Method for preparing aramid fiber fibre composite sheet material

A technology of aramid fibers and composite sheets, which is applied in the direction of papermaking, textiles, papermaking, paper, etc., can solve the problems of increasing costs and increasing procedures, and achieve the effects of simplified manufacturing process, low production cost and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare the blank paper of the special synthetic fiber paper of this embodiment according to the following proportions.

[0017] 70 parts (parts by weight) of poly-m-phenylene isophthalamide amine fiber

[0018] Polyethylene terephthalate fiber 30 parts

[0019] The above-mentioned polym-phenylene isophthalamide fiber has a fineness of 1.5d and a length of 6m / m. The polyethylene terephthalate fiber has a fineness of 1.5d and a length of 6m / m.

[0020] Specific production method:

[0021] The polym-phenylene isophthalamide fiber and the polyethylene terephthalate fiber are respectively decomposed into A and B liquids in a hydraulic decomposer at a concentration of 0.05%. Then mix liquids A and B evenly in the slurry mixing tank and send them to the slurry stabilization box. At the same time, add 5 parts of high molecular weight polyethylene oxide into the pulp stabilization box. According to the conventional method of papermaking and forming, after dehydration and dr...

Embodiment 2

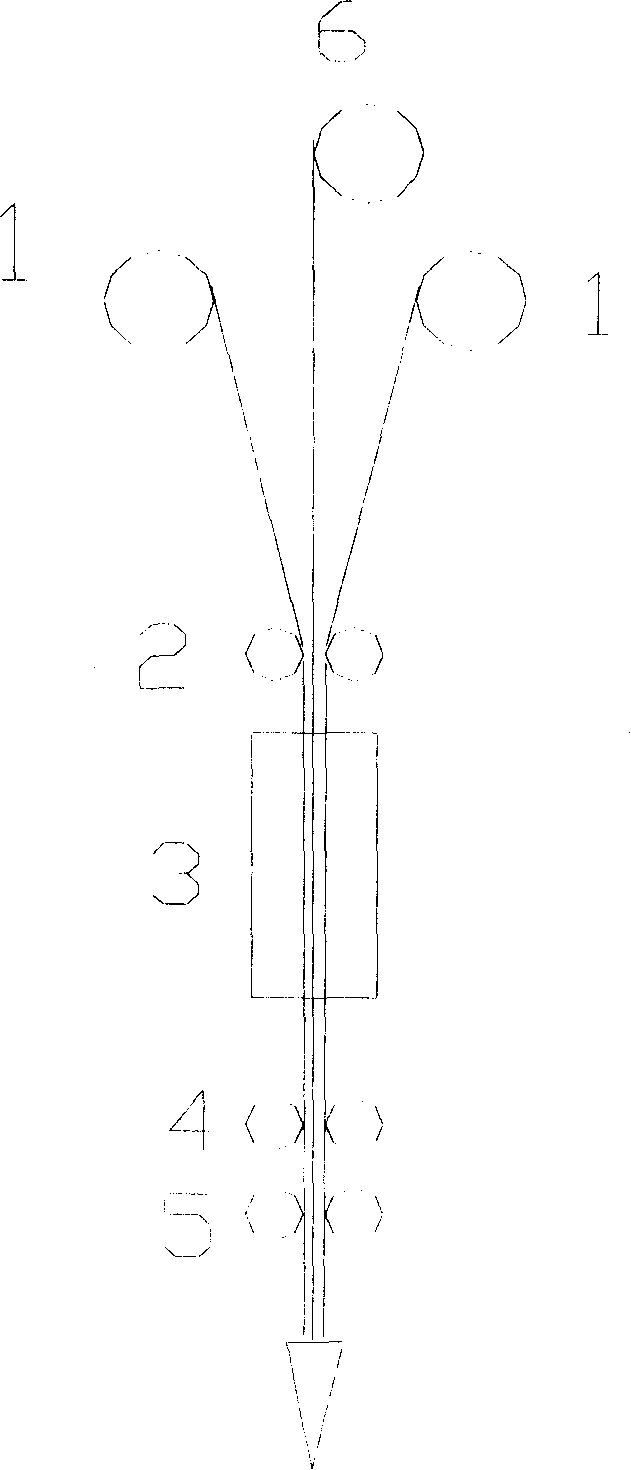

[0022] Embodiment 2: the rough paper produced by the method shown in example 1 is placed on the paper holder (1) of accompanying drawing. Put the polyphenylene sulfide paper on the paper holder (6). The "rough paper" on the roll (1) and the polyphenylene sulfide paper on the paper frame (6) are pre-pressed by the traction roller (2) (temperature 190-200°C, line pressure 200N / cm), and then sent into the In the drying tunnel (3), the paper is preheated to 250-26°C in the drying tunnel and then sent to the hot rolling roller for pressure heat sealing (temperature 280-300°C, line pressure 3000N / cm), and then enters the quenching roller for cooling , Shaped, that is, a sheet with a thickness of 0.3-0.35mm.

Embodiment 3

[0023] Embodiment 3: The production method of the sheet is basically the same as that of Embodiment 1. The difference is that the rough paper is made of polyphenylene sulfide fiber instead of polyethylene terephthalate, and a sheet with a thickness of 0.3-0.35mm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com