Hydrogel and method for preparing same

A technology of hydrogel and water-soluble monomers, which is applied in the field of polymers, can solve the problems of cumbersome weighing of cross-linking agents and initiators to prepare buffer solutions, long duration of the preparation process, and energy-consuming problems, so as to achieve good mechanical properties, The method is simple and the effect is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

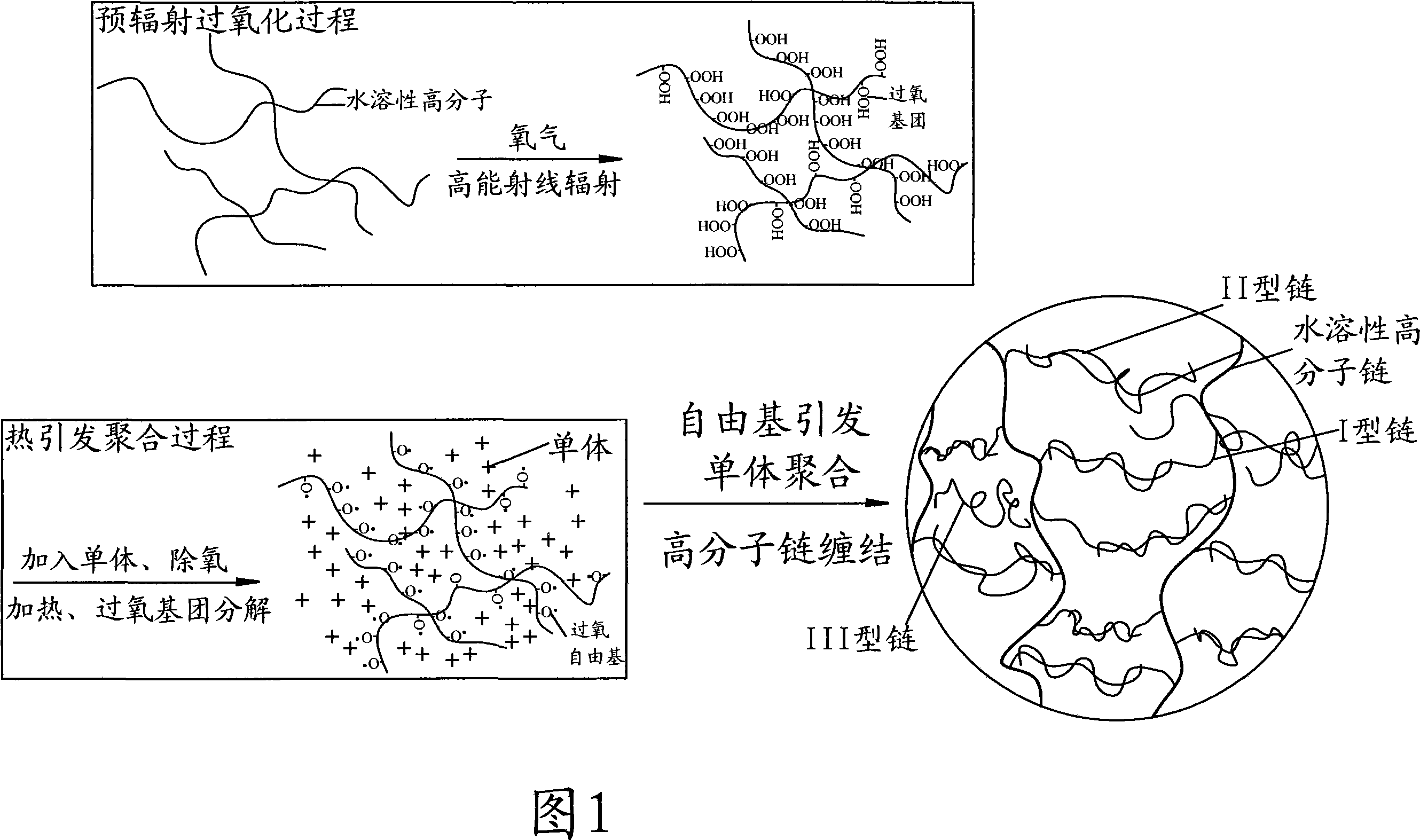

Method used

Image

Examples

Embodiment 1

[0049] Before the pre-irradiation, oxygenate the polyvinylpyrrolidone PVP (K30) powder for 1 hour, and irradiate it with a cobalt source for 4 hours. The temperature during the irradiation is 100 ℃, and the dose rate is 200 grays per minute. The PVP powder and water are prepared into a solution, and the solution is mixed with acrylic acid. The mass percentage of PVP in the mixed solution is 0.25%, and the mass percentage of acrylic acid is 74.75%. The container will hold the mixed solution after 15 minutes of nitrogen flow. Seal and heat, the reaction temperature is 70℃, and the product will be obtained after 12 hours of reaction. Under the condition of 25℃, the compressive strength of the electronic universal testing machine is tested, and the beam speed is controlled to 10mm / min. The measurement shows that the water content of the sample is 80%, and its compressive strength is 1.45MPa.

Embodiment 2

[0051] Prepare a solution of polyvinyl alcohol (dealcoholization degree above 90%) with water at a mass ratio of 1 / 3, and use a cobalt source to irradiate for 1 hour with a temperature of 40°C and an irradiation dose rate of 300 Gray every minute, after the end of the irradiation, mix the solution with acrylamide. The mass percentage of polyvinyl alcohol in the mixed solution is 15%, and the mass percentage of acrylamide is 40%. After 30 minutes of argon, The container containing the mixed solution is sealed and heated. The reaction temperature is 35℃. The product will be obtained after 24 hours of reaction. At 25℃, the compressive strength of the electronic universal testing machine is tested, and the beam speed is controlled to 5mm / min. . The measurement shows that when the water content of the sample is 90%, the compressive strength is 24.36MPa.

Embodiment 3

[0053] The carboxymethyl chitosan is mixed with water in a mass ratio of 1 / 20 to form a solution, and the cobalt source is used for oxygen irradiation for 3 hours, the temperature is 0°C during the irradiation, and the irradiation dose rate is 250 grays per minute. After the irradiation, the solution was mixed with N-vinylpyrrolidone, the mass percentage of carboxymethyl chitosan in the mixed solution was 2.4%, the mass percentage of N-vinylpyrrolidone was 49.6%, and helium gas After 10 minutes, the container containing the mixed solution was sealed and heated. The reaction temperature was 50°C. The product was obtained after 3 hours of reaction. At 25°C, the compression strength was tested with an electronic universal testing machine to control the beam speed It is 10mm / min. The measurement shows that when the water content of the sample is 80%, the compressive strength is 9.41 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com