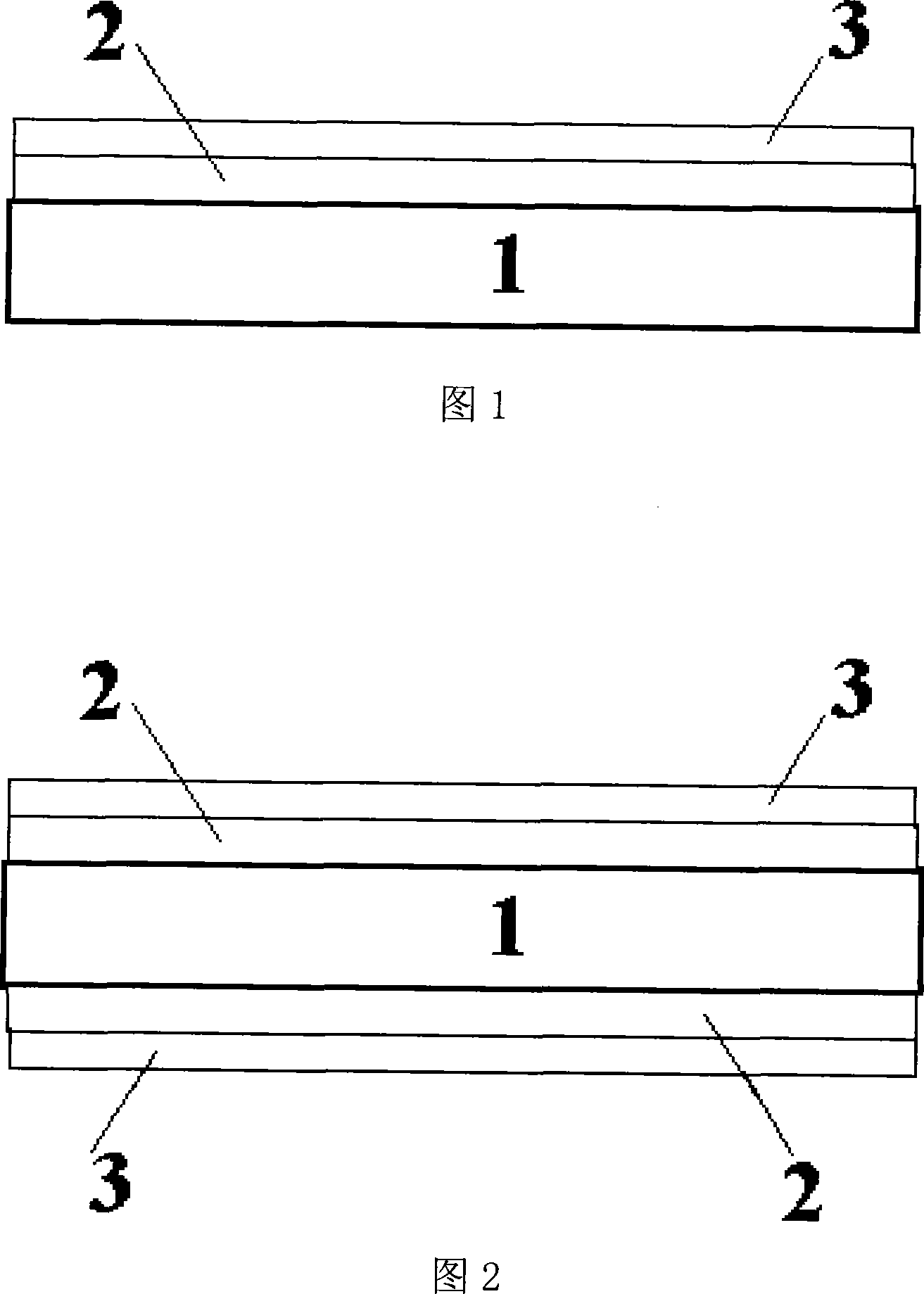

Visible light anti-reflection and ultraviolet radiation cut-off bifunctional coated glass and preparation method thereof

A coated glass and anti-reflection technology, which is applied in the field of visible light anti-reflection and ultraviolet cut-off dual-function coated glass and its preparation, can solve the problems of complex process and difficult control of the amount of cerium ion addition, and achieve simple and flexible process and improve the transmission of visible light The effect of low index and refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of coated glass with both visible light anti-reflection and ultraviolet cut-off dual-functional composite film layers by spraying method includes the following steps:

[0023] 1) First, the glass substrate to be coated is cleaned and dried; the visible light transmittance of the substrate glass is 89%;

[0024] 2) Prepare a spraying solution containing titanium and cerium, the spraying solution is composed of butyl titanate and soluble cerium nitrate, the concentration of titanium and cerium is adjusted with ethanol, and the mass percentage of the two after conversion into titanium oxide and cerium oxide is: Titanium 40%, cerium oxide 60%.

[0025] 3) Prepare a silicon-containing spraying liquid, which is composed of tetraethyl orthosilicate, water and ethanol, using ammonia as a catalyst, and the mass fraction of silicon in the spraying liquid is 3%.

[0026] 4) under normal pressure, first spray the first layer of titanium and cerium-containing spraying l...

Embodiment 2

[0029] Preparation of coated glass with visible light anti-reflection / ultraviolet cut-off dual-functional composite film layer by dipping and pulling method includes the following steps:

[0030] 1) First, the glass substrate to be coated is cleaned and dried; the visible light transmittance of the glass substrate is 89%;

[0031] 2) Prepare an impregnation solution containing titanium and cerium. The impregnation solution is composed of butyl titanate and soluble cerium nitrate. The concentration of titanium and cerium is adjusted with ethanol, and the mass percentage of the two after conversion into titanium oxide and cerium oxide is: Titanium 50%, cerium oxide 50%.

[0032] 3) Prepare a silicon-containing impregnating solution, which is composed of tetraethyl orthosilicate, water and ethanol, using ammonia as a catalyst, and the mass fraction of silicon in the impregnating solution is 4%.

[0033] 4) Under normal pressure, first immerse a 100mm long, 100mm wide, and 3mm th...

Embodiment 3

[0036] Preparation of coated glass with visible light anti-reflection / ultraviolet cut-off dual-functional composite film layer by spraying method, comprising the following steps:

[0037] 1) First, the glass substrate to be coated is cleaned and dried; the visible light transmittance of the substrate glass is 89%;

[0038] 2) Prepare a spraying solution containing titanium and cerium, the spraying solution is composed of butyl titanate and soluble cerium nitrate, the concentration of titanium and cerium is adjusted with ethanol, and the mass percentage of the two after conversion into titanium oxide and cerium oxide is: Titanium 60%, cerium oxide 40%.

[0039] 3) Prepare a silicon-containing spraying liquid, which is composed of tetraethyl orthosilicate, water and ethanol, using ammonia as a catalyst, and the mass fraction of silicon in the spraying liquid is 3%.

[0040] 4) under normal pressure, first spray the first layer of titanium and cerium-containing spraying liquid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com