Microorganism catalytic synthesis process for mesoporous nano powder body hydroxyapatite

A technology of nano-hydroxyapatite and hydroxyapatite, applied in the direction of fermentation, etc., can solve the problems of complex preparation process, low activity, high cost, etc., achieve strong hydrophobicity and bio-affinity, simple preparation process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

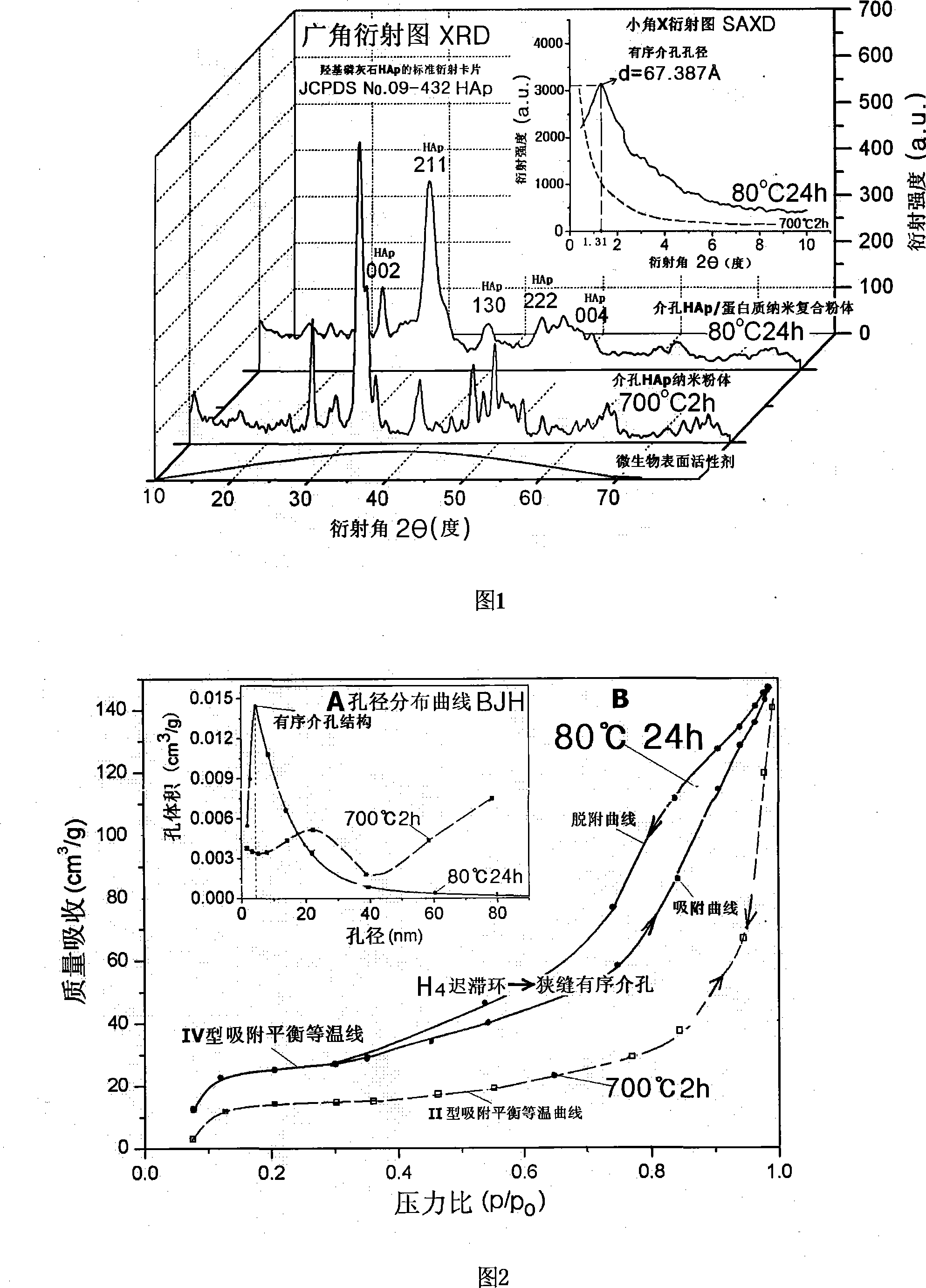

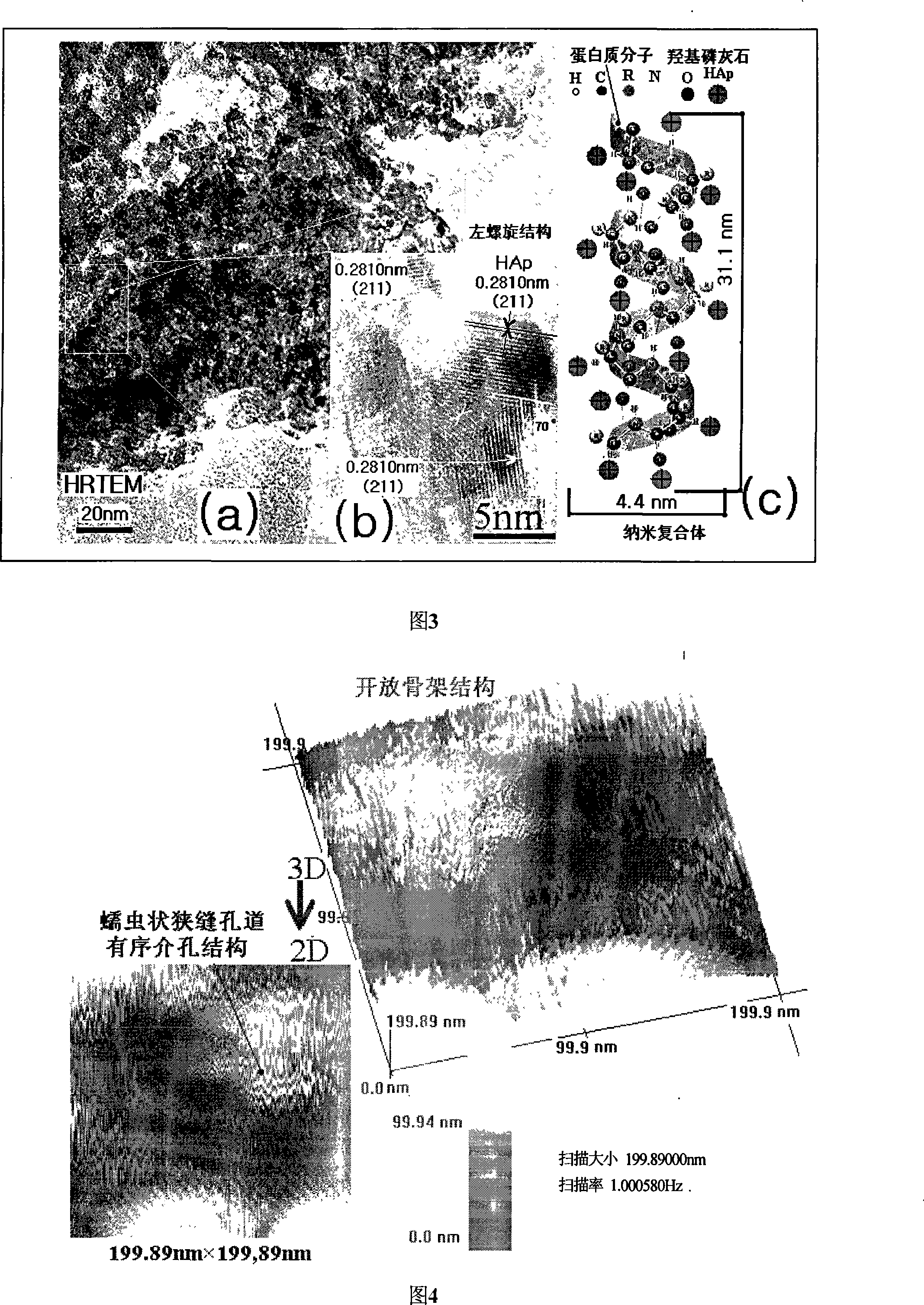

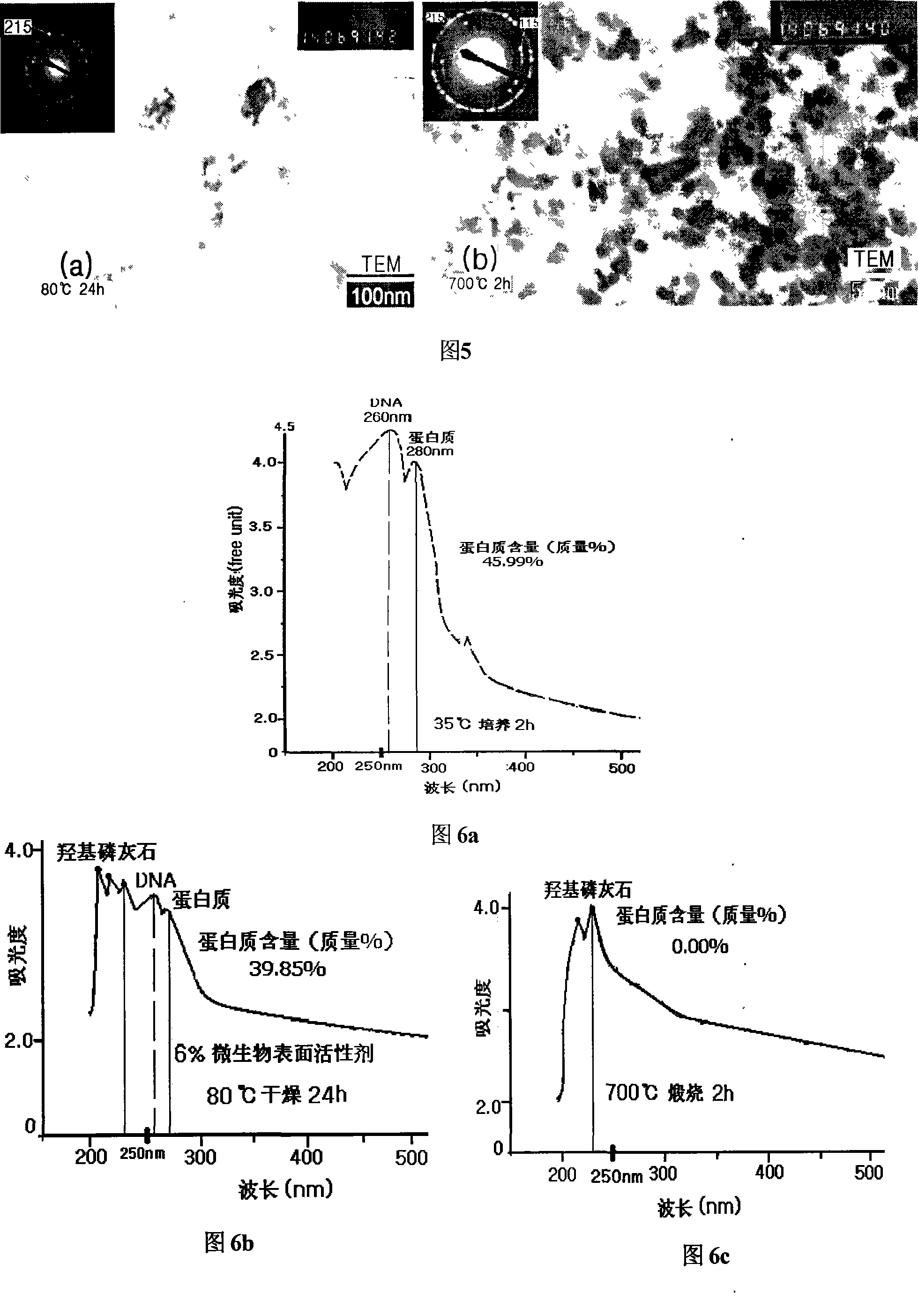

Embodiment 1

[0027] Example 1: 150 ml of 25 g / L glycolipid-based biosurfactant Coccidia sophorolipid aqueous solution was added at room temperature with 6 g of sugar additives, stirred at room temperature for 20 minutes, and emulsified at 25 ° C for 50 minutes to obtain fermented emulsion A , and then, 50ml of 0.5mol / L CaCl 2 The solution was added to emulsion A, and magnetic stirring was continued for 30 minutes to allow Ca 2+ It can be fully adsorbed in the nanovesicle structure of microbial cells. Slowly add 0.5 mol / L phosphoric acid solution dropwise at a rate of 10 drops per minute, and make Ca / P (molar ratio) = 1.67, adjust pH = 10 with 5 mol / L NaOH solution, continue magnetic stirring for 0.5 h, let the cell structure part Mineralize the sediment, then let it stand for 20 hours, centrifuge at 5000 rpm for 5 minutes, wash twice with water and wash once with alcohol to remove Cl - 、Na + and H 2 O. Finally, the precipitate was dried in a drying oven at 70°C for 20 hours to obtain ...

Embodiment 2

[0028] Example 2: 150ml of 50g / L glycolipid-based biosurfactant rhamnolipid aqueous solution was added at room temperature with 4.5g of sugar additives, stirred at room temperature for 50 minutes, and emulsified at 35°C for 30 minutes to obtain fermented emulsion A. Then 1.65g Ca(OH) 2 Add the powder to the emulsion A, continue magnetic stirring for 50 minutes, let the Ca 2+ It can be fully adsorbed in the nanovesicle structure of microbial cells. Slowly add 0.3 mol / L ammonium dihydrogen phosphate solution dropwise at a speed of 20 drops per minute, and make Ca / P (molar ratio) = 1.67, continue magnetic stirring for 1 h, allow the mineralization and deposition of the cell structure part, then let stand for 15 h, and Centrifuge at 5000 rpm for 3 minutes, wash 3 times with water and wash 2 times with alcohol to remove OH- and NH 4 + and H 2 O. Finally, dry the precipitate in a drying oven at 80°C for 24 hours to obtain a mesoporous HAp / protein nanocomposite powder sample with ...

Embodiment 3

[0035] Example 3: 150ml of 20g / L glycolipid-based biosurfactant trehalose lipid aqueous solution was stirred at room temperature with 9g of sugar additives, stirred at room temperature for 30 minutes, and emulsified at 20°C for 1 hour to obtain emulsion A, and then 40ml of 0.6mol / L Ca(NO 3 ) 2 Add the solution to Emulsion A and continue magnetic stirring for 1 hour to allow Ca 2+ It can be fully adsorbed in the nanovesicle structure of microbial cells. Slowly add 0.6mol / L sodium phosphate solution dropwise at a speed of 15 drops per minute, and make Ca / P (molar ratio)=1.8, adjust pH=12 with 5mol / L NaOH solution, continue magnetic stirring for 45 minutes, let the cell structure Partially mineralize and deposit, then stand still for 18 hours, high-speed centrifuge (5000 rpm, 10 minutes), wash twice with water and wash once with alcohol to remove NO 3 - and Na + and H 2 O. Finally, the precipitate was dried in a drying oven at 90°C for 30 hours to obtain a mesoporous HAp / p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| deformity rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com