Fenofibrate pellet and method for preparing the same

A technology of fenofibrate and pellets, which is applied in the field of fenofibrate solid dispersion pellets, can solve the problems of low dissolution rate and achieve the effects of good reproducibility, high yield, and simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

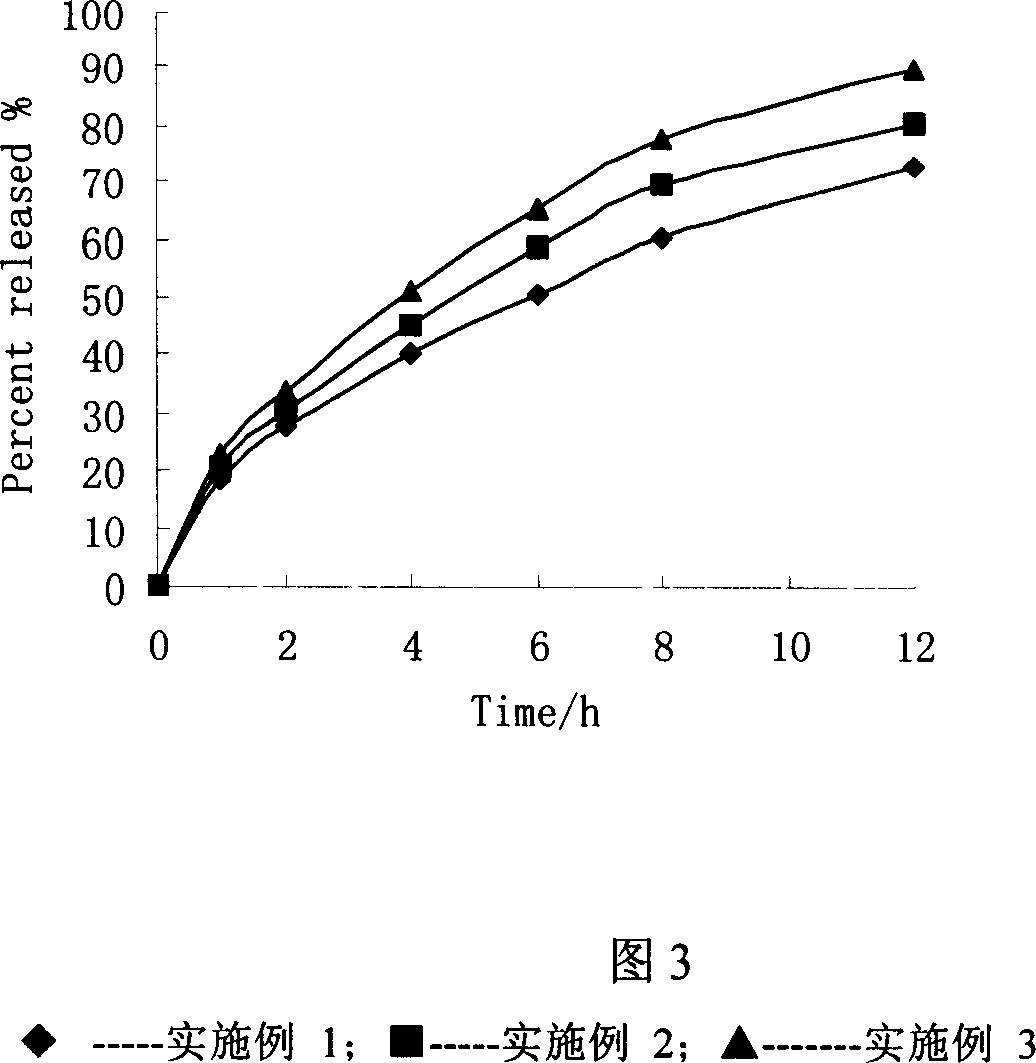

Embodiment 1

[0025] Example 1 Preparation of fenofibrate pellets

[0026] Fenofibrate 2.5g, acrylic resin Euragit 5.0g, micro-powder silica gel 2.5g.

[0027]Put fenofibrate (2.5g) and Eu RS (5.0g) in a 50ml beaker, add 5-30ml of ethanol or methanol and 5-30ml of chloroform or dichloromethane, and stir to dissolve in a quick mixer. After dissolving completely Then add micro-powder silica gel and suspend evenly to make a "drug solution". Place 100-200ml of distilled water in a column-shaped reactor, control the temperature at 20-25°C, and slowly add the "medicine solution" under the stirring of a propeller stirring paddle (300-800rpm) to form O / W half-emulsion droplets. Stir for 20 minutes, add 100-200ml of distilled water, and continue to stir for 40-60 minutes. Under the action of stirring, ethanol or methanol will continue to diffuse into the water, and the drugs and polymer materials in the emulsion will precipitate and deposit on the inner and outer surfaces of the micro-powder silica gel....

Embodiment 2

[0029] Example 2 Preparation of fenofibrate sustained-release pellets

[0030] Fenofibrate 3.0g, acrylic resin Euragit 6.0g, micro-powder silica gel 3.0g.

[0031] Put fenofibrate (3.0g) and Eu RL (6.0g) in a 50ml beaker, add 2.5-15ml of ethanol or methanol and 2.5-15ml of chloroform or dichloromethane, and stir to dissolve in a quick mixer. After it is completely dissolved Then add micro-powder silica gel and suspend evenly to make a "drug solution". Place 100-200ml of distilled water in a column-shaped reactor, control the temperature at 20-25°C, and slowly add the "medicine solution" under the stirring of a propeller stirring paddle (300-800rpm) to form O / W half-emulsion droplets. Stir for 20 minutes, add 100-200ml distilled water containing 0.5% sodium lauryl sulfate as a surfactant, and continue to stir for 40-60 minutes. Under stirring, ethanol or methanol will continue to diffuse into the water and the drug in the emulsion It precipitates with polymer materials and deposits...

Embodiment 3

[0033] Example 3 Preparation of fenofibrate sustained-release pellets

[0034] Fenofibrate 2.0g, ethyl cellulose 4.0g, micro-powder silica gel 2.0g.

[0035] Put 2.0g of fenofibrate and 4.0g of ethyl cellulose in a 50ml beaker, add 2.5-15ml of ethanol or methanol and 2.5-15ml of chloroform or dichloromethane, stir to dissolve in a quick mixer, and add micropowder after it is completely dissolved Silica gel is uniformly suspended to make a "drug solution". Place 120-200ml of distilled water in a cylindrical reactor (with a baffle inside). The temperature is controlled at 20-25℃. Under the stirring of a propeller stirring paddle (300 ~800rpm) Slowly add the "drug solution".

[0036] Place 100-200ml of distilled water in a column-shaped reactor, control the temperature at 20-25°C, and slowly add the "medicine solution" under the stirring of a propeller stirring paddle (300-800rpm) to form O / W half-emulsion droplets. Stir for 20 minutes, add 100-200ml distilled water containing 0.5% T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com