Post processing method for fluorescent powder of luminescent diode

A technology of light-emitting diodes and phosphors, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low luminous brightness and efficacy of phosphors, difficult semiconductor lighting applications, etc., to achieve improved luminous performance, improved emission intensity, and improved crystallization degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

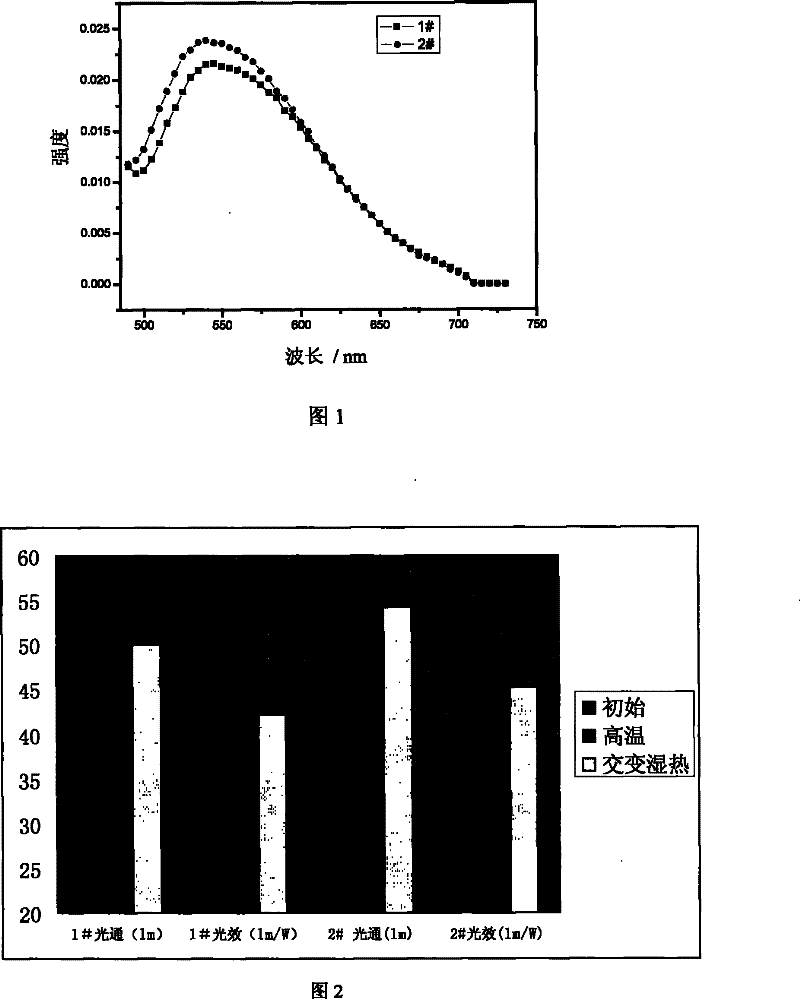

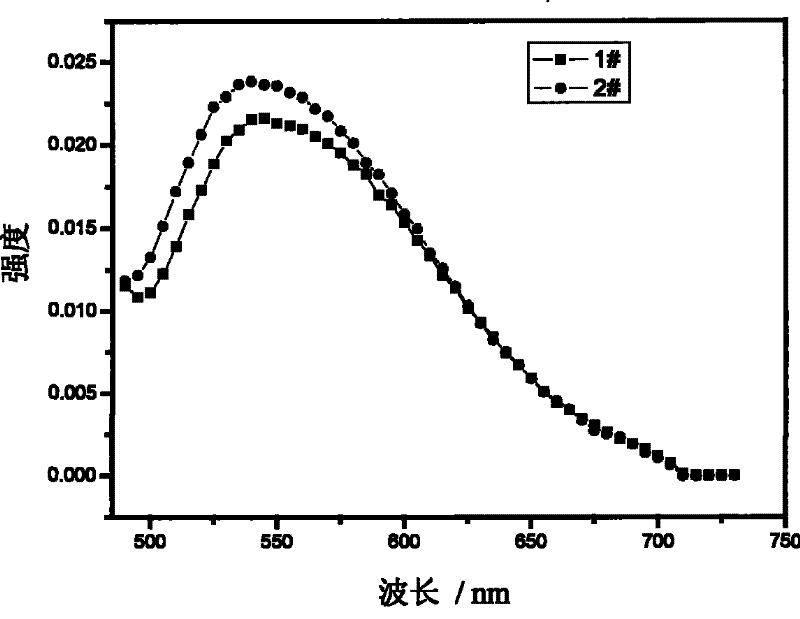

Embodiment 1

[0029] 10gY 2.93 Al 5 o 12 : Ce 0.07Yellow light-emitting fluorescent powder, uniformly dispersed in 10ml of HF aqueous solution with a concentration of 0.5M, stirred at room temperature for 45min, centrifuged, washed with deionized water for 3 times until the pH value is neutral, and then dispersed in HNO with a concentration of 0.5M 3 15ml aqueous solution, stirred at 25°C for 30min, after centrifugation, washed 4 times with deionized water until the pH value was neutral, washed 2 times with absolute ethanol, dried at 110°C; put the dried fluorescent powder in a corundum crucible Inside, under the protection of N2-H2 reducing atmosphere, heat to 1400°C, keep warm for 10h, then cool to room temperature with the furnace and release from the furnace, after crushing, pass through a 400 mesh sieve; take 10ml of absolute ethanol, 0.05g of aminopropyltriethoxy Silane and 10g of fluorescent powder after recovery treatment were prepared into a 50% suspension; while stirring, drop ...

Embodiment 2

[0031] Take 10gY 2.93 Al 5 o 12 : Ce 0.07 Yellow light-emitting phosphor, uniformly dispersed in 10ml of HF aqueous solution with a concentration of 1M, stirred at room temperature for 45min, centrifuged, washed with deionized water for 4 times to neutral pH, and then dispersed in 0.5M HNO 3 15ml aqueous solution, stirred at 25°C for 60min, after centrifugation, washed 4 times with deionized water until the pH value was neutral, washed 2 times with absolute ethanol, dried at 110°C; put the dried fluorescent powder in a corundum crucible Inside, under the protection of N2-H2 reducing atmosphere, heat to 1500 ° C, keep warm for 5 hours, cool to room temperature with the furnace, and take out after being crushed, and pass through a 400-mesh sieve; take 10ml of absolute ethanol, 0.05g of vinyl (2-methoxy ethoxy) silane and 10g of fluorescent powder after recovery treatment are prepared into a 50% suspension; while stirring, drop 0.02g of deionized water accounting for the weigh...

Embodiment 3

[0033] Take 10g of CaS:Eu red light-emitting phosphor, uniformly disperse in 10ml of HF aqueous solution with a concentration of 0.8M, stir at room temperature for 100min, centrifuge, wash with deionized water 4 times until the pH value is neutral, and then disperse in HNO with a concentration of 1.2M 3 15ml aqueous solution, stirred at 25°C for 60min, after centrifugation, washed 4 times with deionized water until the pH value was neutral, washed 2 times with absolute ethanol, dried at 110°C; put the dried fluorescent powder in a corundum crucible Inside, under the protection of the air, heat to 900 ° C, keep warm for 5 hours, cool to room temperature with the furnace, and take out the furnace, after crushing, pass through a 400-mesh sieve; take 10ml of absolute ethanol, 0.05g of thiopropyl trimethoxy silicon and restore The treated 10g phosphor powder was prepared into a 50% suspension; while stirring, drop 0.02g of deionized water accounting for the weight of the phosphor po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com