Linear illuminants with special-shaped cross-section

A linear light-emitting, special-shaped cross-section technology, applied in the direction of light guide, electric light source, light source fixation, etc. of the lighting system, can solve the problems of interlayer peeling, light leakage, leakage, etc., and achieve the effect of reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

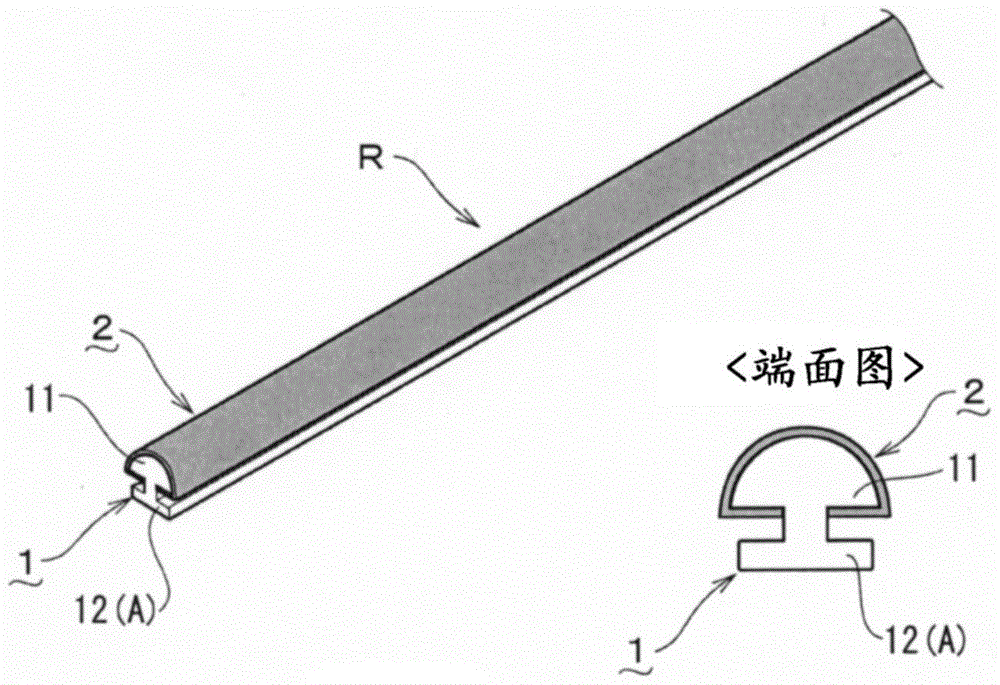

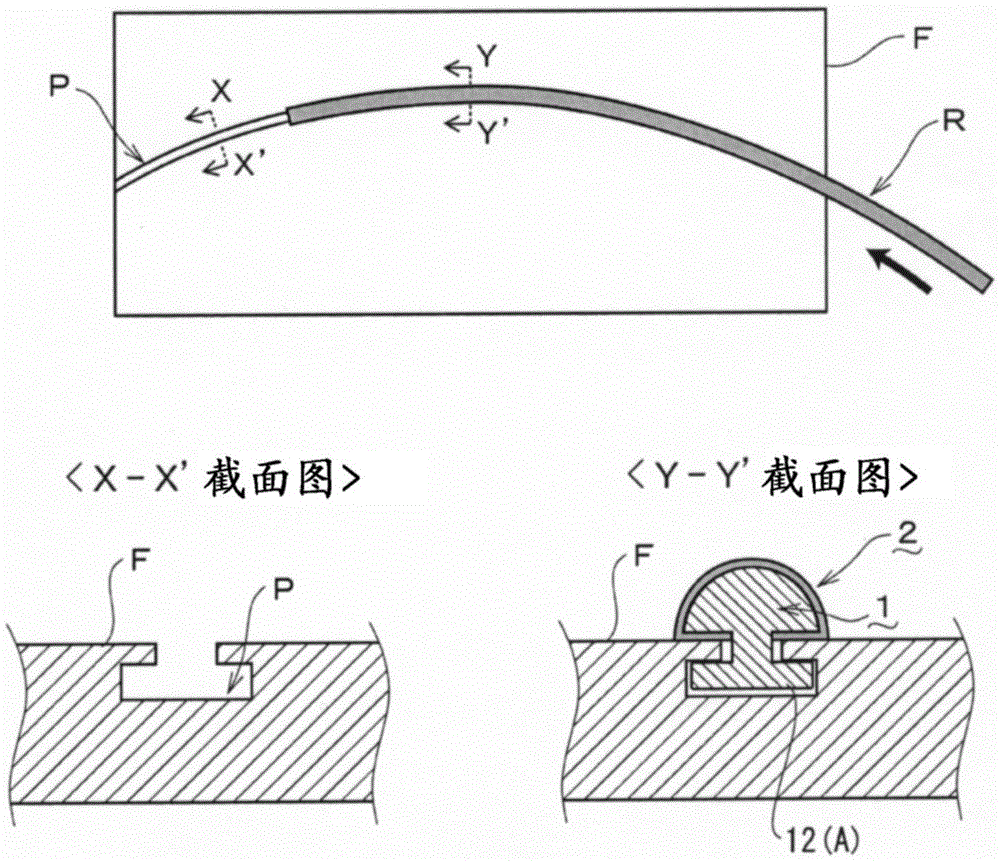

[0041] according to figure 1 and figure 2 Example 1 of the present invention will be described. In addition, in this figure, a portion indicated by reference numeral 1 is a core layer, and a portion indicated by reference numeral 2 is an outer cladding layer.

[0042] Composition of linear illuminants

[0043] First, in Example 1, an outer cover layer 2 made of a translucent resin is formed to cover an arbitrary portion desired to emit light on the surface of a core layer 1 made of a transparent resin, thereby constituting a luminous body R (refer to figure 1 ). In addition, the core layer 1 is formed into a profiled cross-sectional shape, forming a semicircular cross-sectional light-guiding portion 11 and a cross-sectional T-shaped rib-shaped protrusion 12 formed on the planar portion of the light-guiding portion 11 .

[0044]In addition, in this embodiment, PMMA (polymethyl methacrylate) with a refractive index of 1.49 is used for the material of the core layer 1, and t...

Embodiment 2

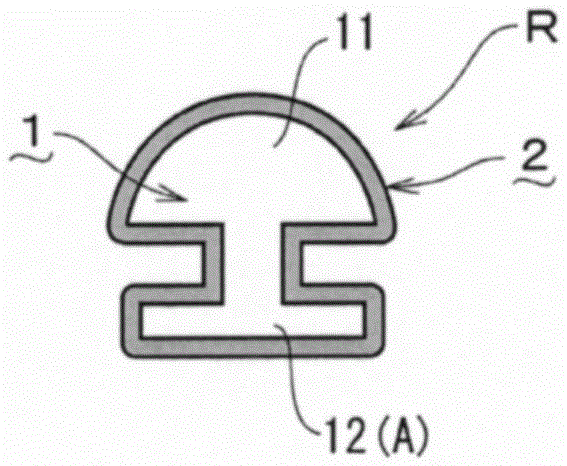

[0056] Below, according to image 3 Example 2 of the present invention will be described. In this Example 2, the overcoat layer 2 is formed on the entire surface of the core layer 1 having a shaped cross-section similar to that of the Example 1, thereby constituting the main body R of the luminous body. Thereby, the cover layer 2 of the attachment part A can be formed thinner than the conventional one, and therefore, the leakage of light from the mounting surface side of the luminous body main body R can be suppressed.

[0057] In addition, by forming the outer cover layer 2 in a cylindrical shape over the entire surface of the core layer 1 as described above, since the outer cover layer 2 has a ring shape, there is no problem that the outer cover layer 2 peels off from the end. Also, even when the luminous body R is attached to the fixed object F in a bent state, since the load is not applied only to the outer cover layer 2, delamination is less likely to occur.

Embodiment 3

[0059] Below, according to Figure 4 and Figure 5 Embodiment 3 of the present invention will be described. In this embodiment 3, the core layer 1 protrudes from the semicircular cross-sectional shape of the main light-emitting portion 11 with an arrow-shaped tendon-shaped protruding portion 12 to form the attachment portion A of the luminous body R ( Figure 4 reference). Thus, if Figure 5 (a) As shown in (b), the attachment part A can be pushed into the recess P of the fixed object F in the depth direction of the groove, and the luminous body R can be fixed on the fixed object F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com