Red-light-emitting glass ceramic and preparation method thereof, and LED/LD light emitting device

A technology of glass ceramics and light-emitting devices, which is applied in the direction of optical elements, lighting devices, and components of lighting devices used to change the spectral characteristics of emitted light, to achieve excellent performance, excellent device performance, and excellent thermal stability of light emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Analytically pure SiO 2 , Al 2 O 3 , MgO and Eu 2 O 3 Powder, according to 40SiO 2 : 35Al 2 O 3 : 24MgO: 1Eu 2 O 3 (molar ratio) is accurately weighed and placed in an agate ball mill, mixed and ground evenly, placed in an alumina crucible, placed in a tube furnace with nitrogen-hydrogen mixed gas, heated to 1450 ° C and kept warm It was melted for 1 hour. The melt is cooled with the furnace to obtain the precursor glass. Still in a mixed atmosphere of nitrogen and hydrogen, the bulk glass was heated to 1100° C. and kept for 20 minutes to crystallize it to obtain a red light-emitting glass-ceramic sample.

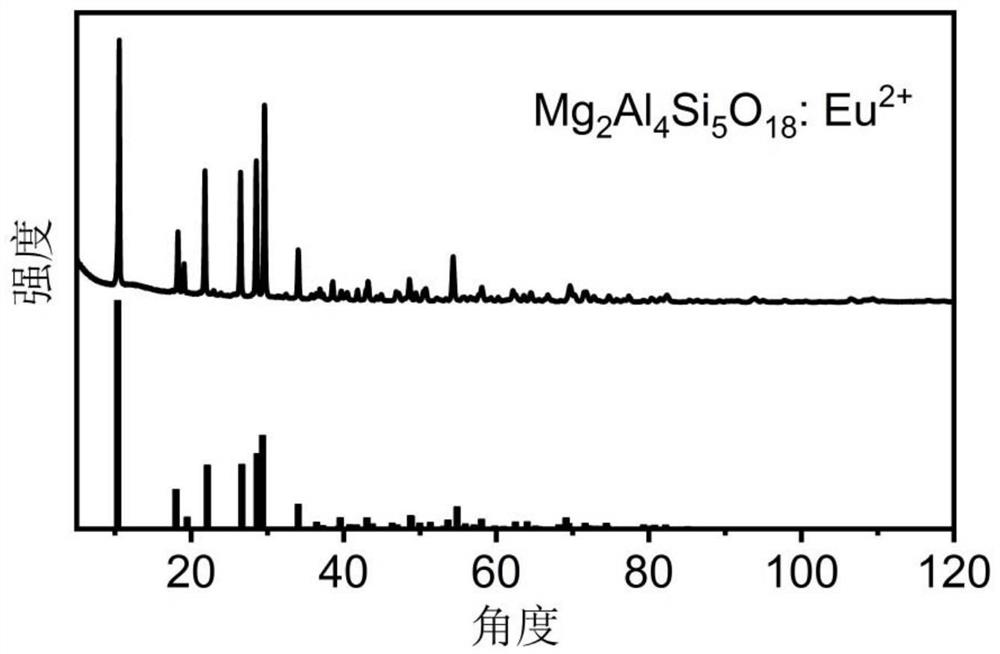

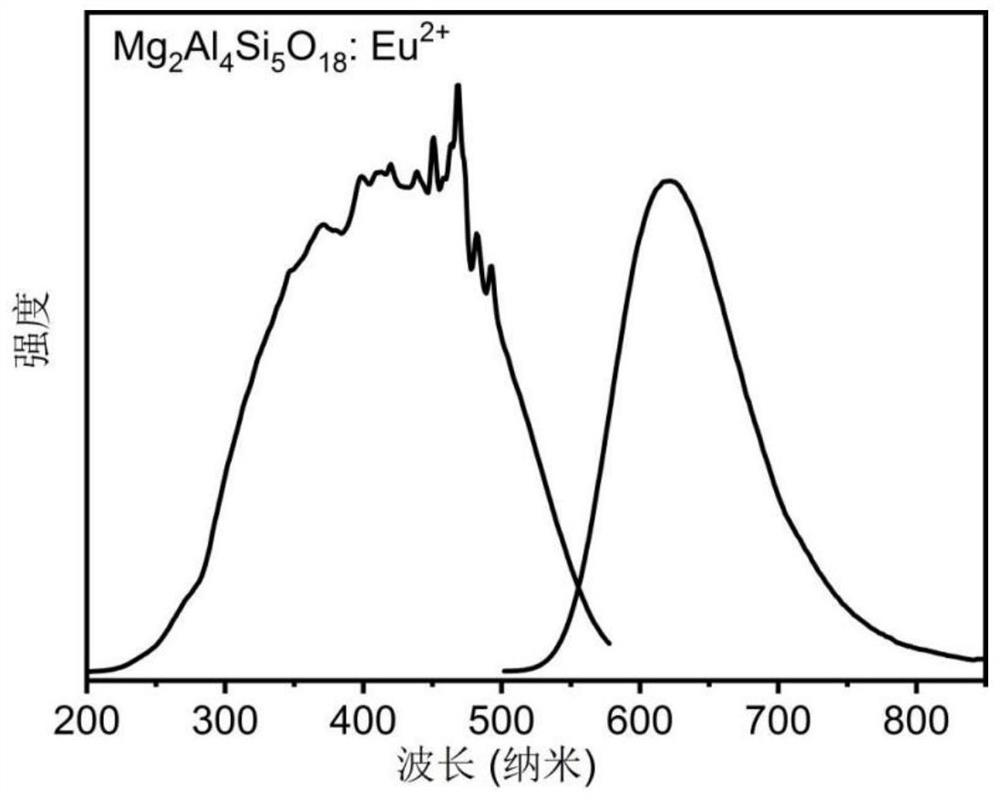

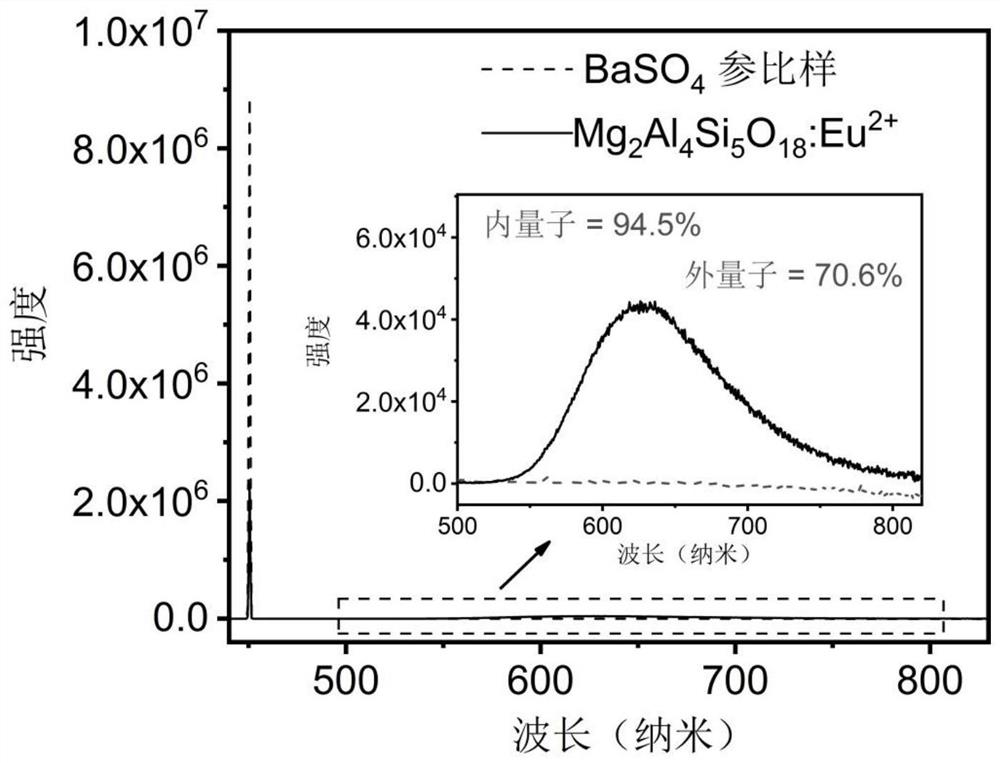

[0049] X-ray diffraction data showed that the prepared Mg 2 Al 4 Si 5 O 18 :Eu 2+ Micron-ceramics (such as figure 1 shown). figure 2 For the excitation and emission spectra of the sample at room temperature, the glass ceramic can emit light in the wavelength range of 500-850 nm under the excitation of near-ultraviolet light and blue light, and the e...

Embodiment 2

[0051] Analytically pure SiO 2 , Al 2 O 3 , MgO, CaO and Eu 2 O 3 Powder, according to 40SiO 2 : 30Al 2 O 3 : 20MgO: 9CaO: 1Eu 2 O 3 (molar ratio) is accurately weighed and placed in an agate ball mill, mixed and ground evenly, placed in an alumina crucible, placed in a tube furnace with a nitrogen-hydrogen mixture, heated to 1700 ° C and kept warm It was melted for 8 hours. The melt is cooled with the furnace to obtain the precursor glass. Still in the mixed atmosphere of nitrogen and hydrogen, the lower block glass was heated to 700° C. and kept for 12 hours to crystallize it to obtain a red light emitting glass ceramic sample.

[0052] After testing, Mg was prepared 1.5 Ca 0.5 Al 4 Si 5 O 18 :Eu 2+ Nanocrystalline glass ceramics, the luminous internal / external quantum efficiency is 90% / 70% respectively. The device performance was tested by coupling the red-emitting sample to a blue-light laser, and the maximum luminous flux and lumen efficiency were ~250 lu...

Embodiment 3

[0054] Analytically pure SiO 2 , Al 2 O 3 , MgO, BaO and Eu 2 O 3 Powder, according to 40SiO 2 : 30Al 2 O 3 : 20MgO: 9BaO: 1Eu 2 O 3 (molar ratio) is accurately weighed and placed in an agate ball mill, mixed and ground evenly, placed in an alumina crucible, placed in a tube furnace with a nitrogen-hydrogen mixture, heated to 1700 ° C and kept warm 30 minutes to melt. The melt is cooled with the furnace to obtain the precursor glass. Still in the mixed atmosphere of nitrogen and hydrogen, the lower block glass was heated to 1000° C. and kept for 4 hours to make it crystallized to obtain a red light emitting glass ceramic sample.

[0055] After testing, Mg was prepared 1.5 Ba 0.5 Al 4 Si 5 O 18 :Eu 2+ Microcrystalline glass ceramics, the luminous internal / external quantum efficiency is 96% / 75% respectively. The device performance was tested by coupling the red-emitting sample to a blue-light laser, and the maximum luminous flux and lumen efficiency were ~260 lu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com