Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

An iron oxyhydroxide, adsorption material technology, applied in iron oxide/iron hydroxide, alkali metal oxide/hydroxide, chemical instruments and methods, etc., can solve the problems of difficult recovery and difficult operation of adsorbed substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I-1

[0197] Ferric chloride (FeCl 3 ·6H 2 O) dissolved in water to a concentration of 0.1 mol / l. A 2 mol / l NaOH aqueous solution was added to the resulting solution while stirring at room temperature so that the pH of the solution was 4. The precipitated product generated in the solution was left to stand for 24 hours, followed by suction filtration, whereby a precipitate was obtained. The resulting precipitate was dried at 50 °C for 48 hours in an oven to obtain FeOOH.

[0198] The BET specific surface area of FeOOH thus obtained is 50.6m 2 / g, and the average particle diameter as an aggregate is 200 μm. The obtained ferric oxyhydroxide was placed in pure water so that the slurry concentration (weight percentage of dry ferric oxyhydroxide in water) reached 5%, and then the mixture was stirred at room temperature for 5 minutes. After stirring, the resulting mixture was filtered with suction to obtain ferric oxyhydroxide. The obtained iron oxyhydroxide was dried at 55°C for ...

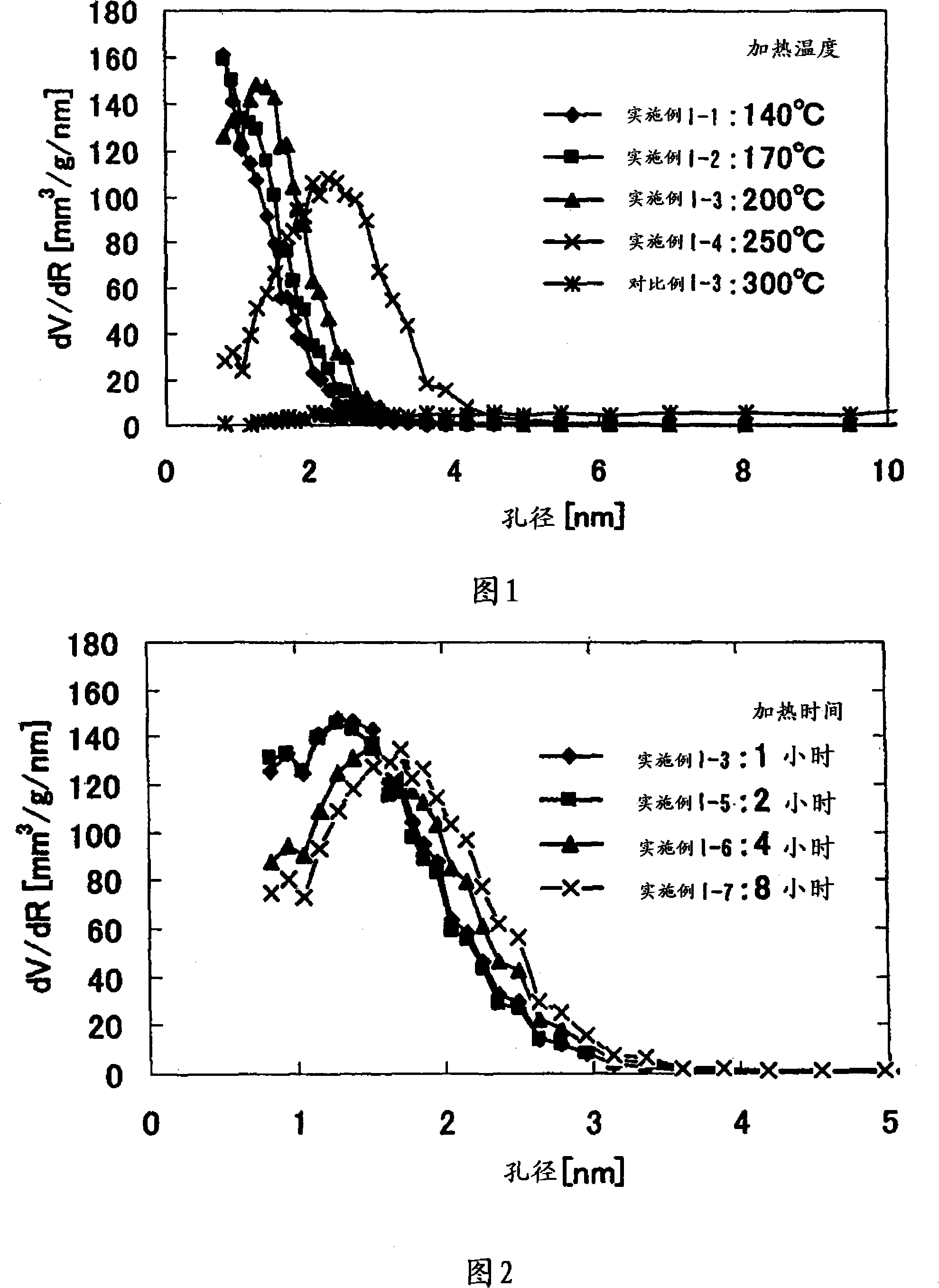

Embodiment I-2~I-7

[0207] The iron oxyhydroxides of Examples I-2 to I-7 were prepared in the same manner as in Example I-1, except that the drying temperature and drying time in step (I-d) were changed as shown in Table 1. Its physical properties are shown in Table 1.

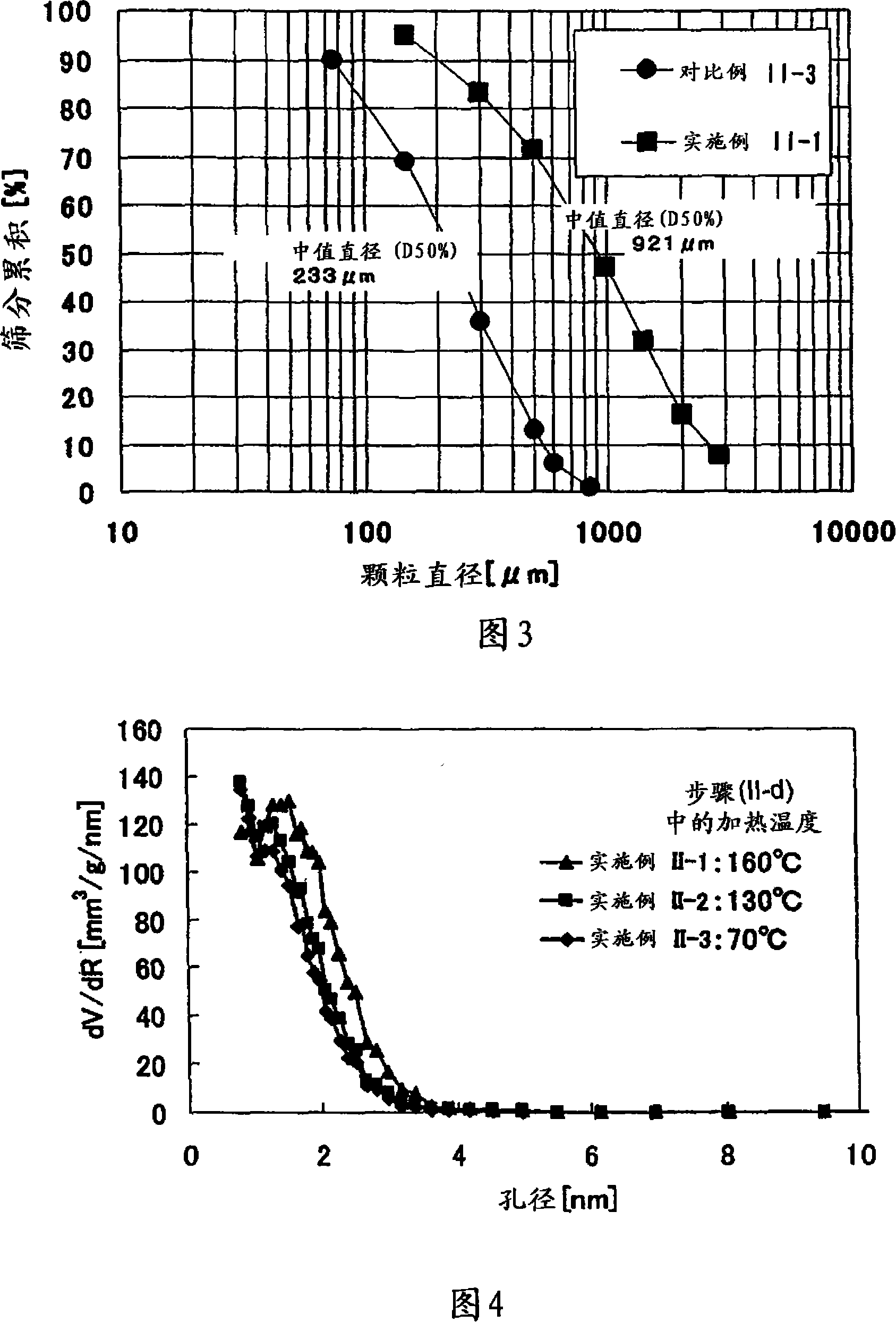

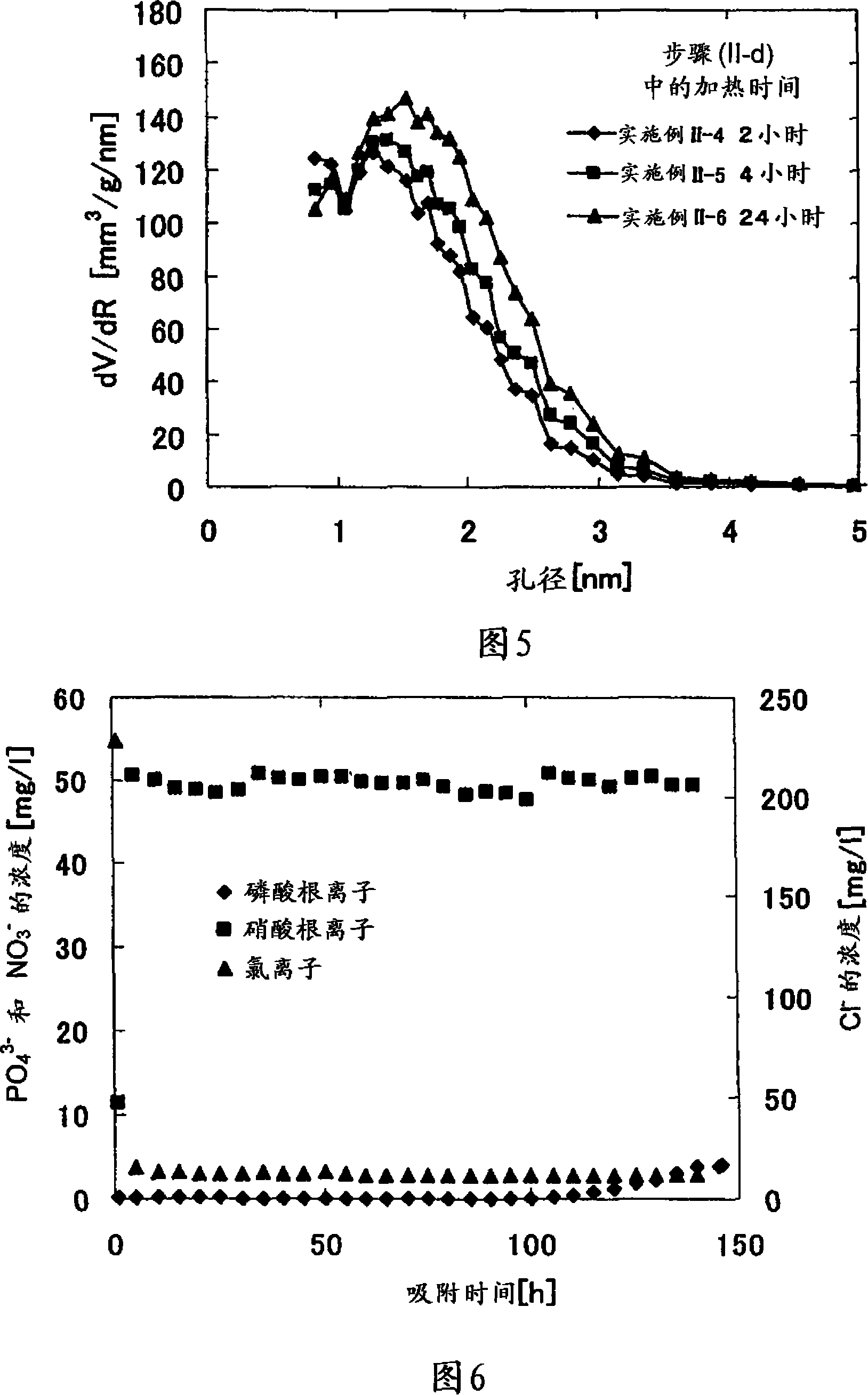

Embodiment II-1

[0224]Ferric chloride (FeCl 3 ·6H 2 O) dissolved in water to a concentration of 0.1 mol / l. A 2 mol / l NaOH aqueous solution was added to the resulting solution under stirring at room temperature so that the pH of the solution was 4. The precipitated product produced in the solution was then allowed to stand for 24 hours and then filtered with suction, whereby a precipitate was obtained. The obtained precipitate was dried in a constant temperature oven at 50° C. for 48 hours in a 100% carbon dioxide atmosphere to obtain FeOOH.

[0225] The obtained ferric oxyhydroxide was placed in pure water so that the slurry concentration (weight percentage of dry ferric oxyhydroxide in water) reached 5%, and then the mixture was stirred at room temperature for 5 minutes. After stirring, the resulting mixture was filtered with suction to obtain ferric oxyhydroxide. The obtained iron oxyhydroxide was dried at 55°C for 24 hours. After drying, the iron oxyhydroxide was heat-treated at 160° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com