Technique for synthesizing tert-butylamine

A synthetic process, the technology of tert-butylamine, applied in the field of fine chemical intermediate production, can solve problems such as difficult industrial production, and achieve the effects of less environmental pollution, loose reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

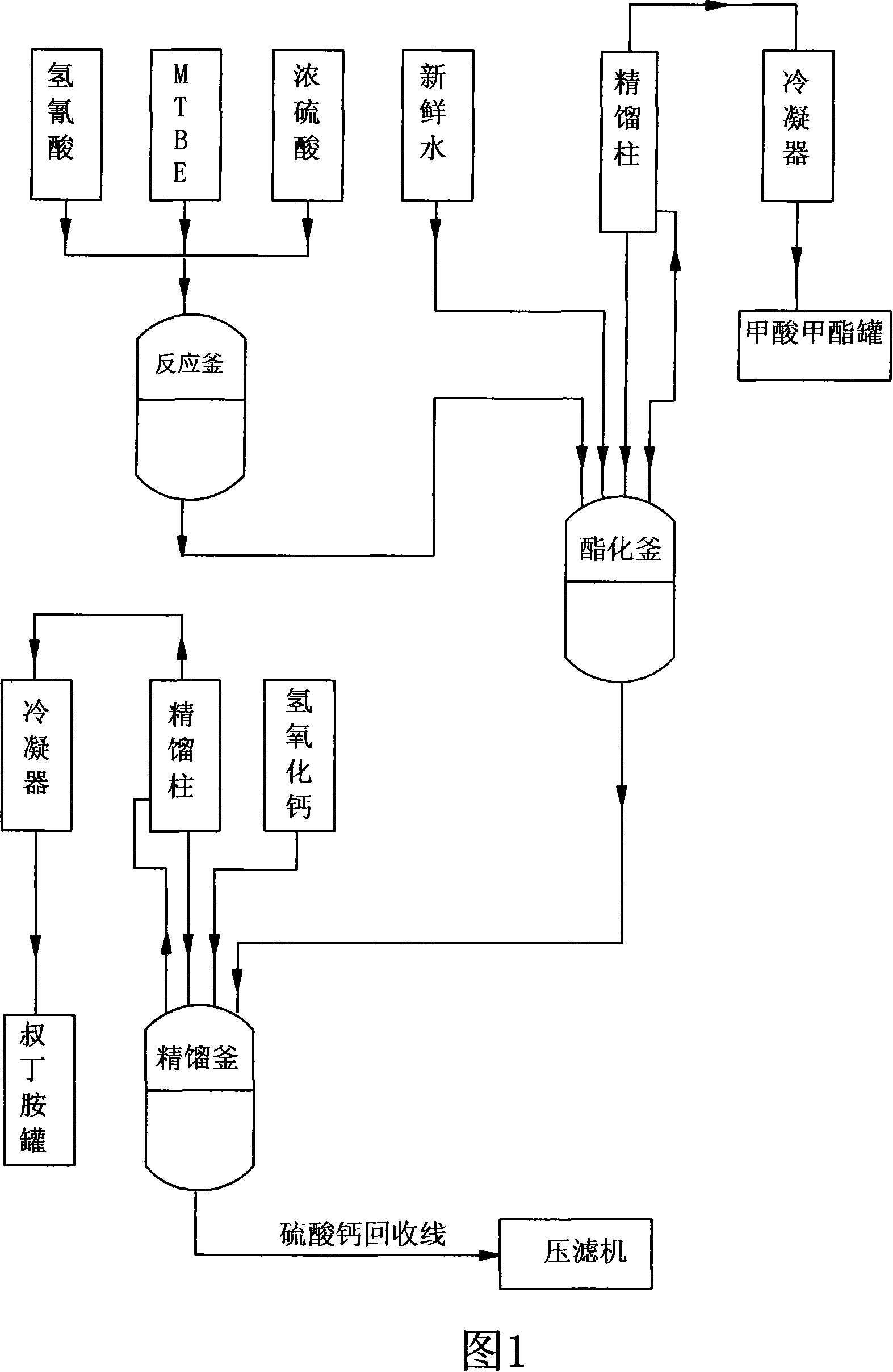

Method used

Image

Examples

Embodiment 1

[0073] (1) The catalytic reaction product is hydrolyzed at 65°C.

[0074] (2) The acid produced by hydrolysis and the alcohol produced by the catalytic reaction undergo esterification reaction to form an ester, and the distillation temperature is controlled at 105° C. to collect corresponding fractions. Simultaneously, incompletely reacted methanol was distilled off.

[0075] (3) Carry out acid-base reaction, adopt the calcium hydroxide solution that mass concentration is 13% to neutralize tert-butylamine sulfate, control distillation temperature 30-100 ℃, then collect the cut of 43 ℃ through rectification and obtain product tert-butylamine. The yield of tert-butylamine is: 90%, and the purity is: >99.5%

[0076] The molar proportion of above each raw material, according to following setting:

[0077] MTBE:hydrocyanic acid=1:1

[0078] MTBE: concentrated sulfuric acid = 1:1

[0079] MTBE:Water=1:3

[0080] MTBE: Calcium Hydroxide = 1: 1.5

[0081] Below is the embodiment...

Embodiment 2

[0084] When methyl tert-butyl ether:concentrated sulfuric acid=1:0.5, the yield of tert-butylamine is 45%, and the purity is 80%.

Embodiment 3

[0086] When methyl tert-butyl ether:concentrated sulfuric acid=1:1, the yield of tert-butylamine is 90%, and the purity is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com