Photovoltaic cell using catalyst-supporting carbon nanotube and method for producing the same

A technology of carbon nanotubes and carbon nanotube layers, applied in the field of manufacturing them, can solve the problems of low conversion efficiency of photovoltaic cells and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

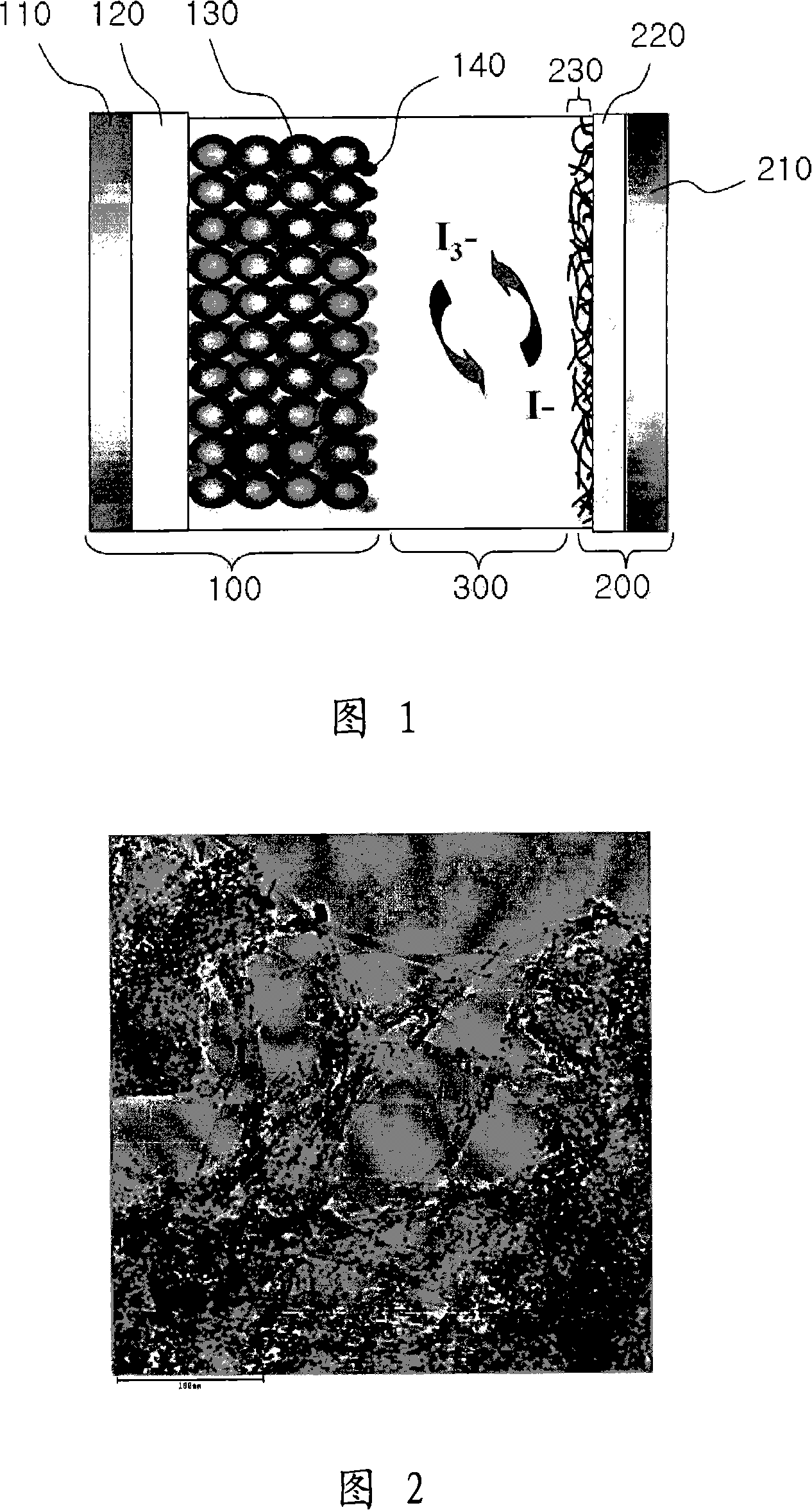

[0043] The preparation of the photoelectrode 100 of the dye-sensitized photovoltaic cell may include: forming a metal oxide film 130 by coating a porous metal oxide on the conductive material 120 placed on the transparent substrate 110, firing the substrate 110, and baking the substrate 110 110 is immersed in a solution containing dissolved dye 140 for a period of time, so that the dye 140 is adsorbed on the surface of the metal oxide film 130 .

[0044] The transparent substrate 110 may be the same as disclosed above in the description about the cathode.

[0045] The metal oxide 130 is selected from titanium oxide, niobium oxide, hafnium oxide, tungsten oxide, tin oxide, zinc oxide, and combinations comprising at least one of the foregoing, but is not limited thereto. In addition, metal oxides can be applied by coating methods such as screen printing or spin coating.

[0046] As for the dye 140, the material used therefor is not limited as long as it is photosensitivity and ...

preparation example 1

[0052] Preparation Example 1: Preparation of Pt-loaded carbon nanotubes

[0053] 0.9422g of H 2 PtCl 6 Soluble in about 20g ethylene glycol. Individually, about 0.25 g of single-walled carbon nanotubes were dispersed in a mixture of about 100 g of water and about 80 g of ethylene glycol. The prepared carbon nanotube solution was added into the Pt solution, and the pH value of the mixture was adjusted to 11 with NaOH. Thereafter, the mixture was allowed to stand at about 105° C. for 2 hours. Then heating at about 110° C. for about 1 hour reduces the platinum to metallic platinum and deposits it on the surface of the carbon nanotubes. After the reaction, the reaction mixture was centrifuged to separate the Pt-loaded carbon nanotubes. The Pt-loaded carbon nanotubes thus isolated are washed with water and subjected to freeze-drying or freeze-drying. Figure 2 shows a transmission electron microscope (TEM) image of a representative sample of the Pt-loaded carbon nanotubes pr...

preparation example 2

[0054] Preparation example 2: preparation of cathode

[0055] About 0.55g of Pt-loaded carbon nanotubes prepared in Preparation Example 1, about 0.5g of glass frit, about 14g of binder, and about 15g of terpineol were mixed and uniformly dispersed for 30 minutes with a 3-roll mill to form paste. Then, the FTO-coated glass substrate was coated with the paste prepared above and dried at about 70° C. for about 30 minutes. Next, the glass substrate was baked at 430° C. for about 20 minutes under a nitrogen atmosphere for surface treatment to prepare a cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com