Method for preparing nano-crystalline and amorphous composite structure yttrium oxide stabilization zirconium oxide spherical powder

A technology for stabilizing zirconia and composite structure, which is applied in the field of preparing high-performance thermal barrier coating by plasma spraying, and preparing nanocrystalline and amorphous composite structure yttria-stabilized zirconia spherical powder, achieving easy mass production, high technical content, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 100kg of zirconium oxychloride and 4.86kg of yttrium chloride crystal powder, add 2000kg of deionized water, and stir evenly to obtain a uniform solution. Add 700kg of ammonia solution with a concentration of 5wt% to the solution, co-precipitate to obtain a gel and perform 2h aging treatment, and obtain about 350kg of stable gel after filtration and washing.

[0040] According to the weight ratio of 1:1, add 350kg of absolute ethanol, after stirring ball milling for 2 hours, and ultrasonically dispersing for 1 hour, a uniform and stable slurry is obtained.

[0041] The uniform and stable gel slurry is spray-dried and granulated by centrifugal spray drying. The inlet temperature is 330°C, the outlet temperature is 170°C, the rotational speed of the centrifugal atomizing disc is 9000r / min, and the cyclone separator is used to collect the granulated product. powder material.

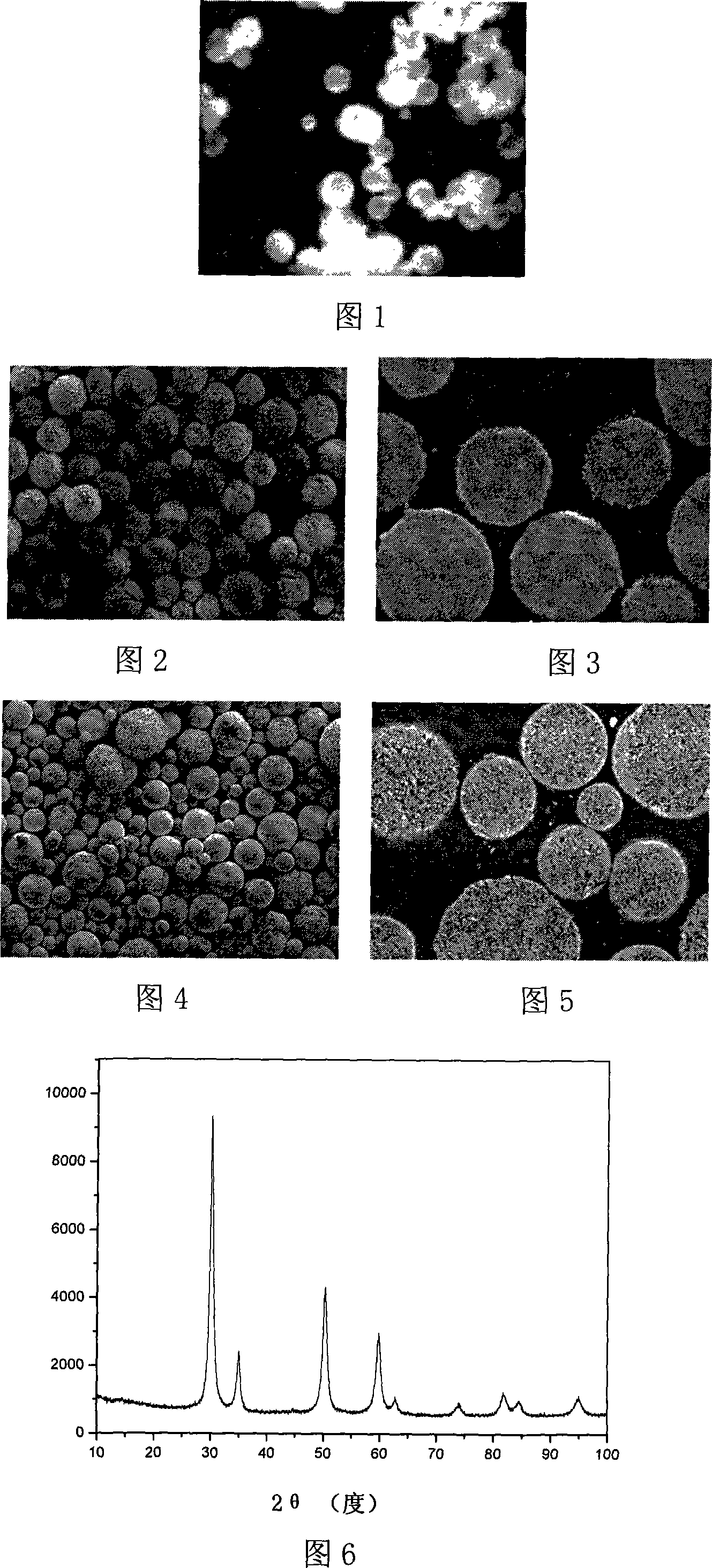

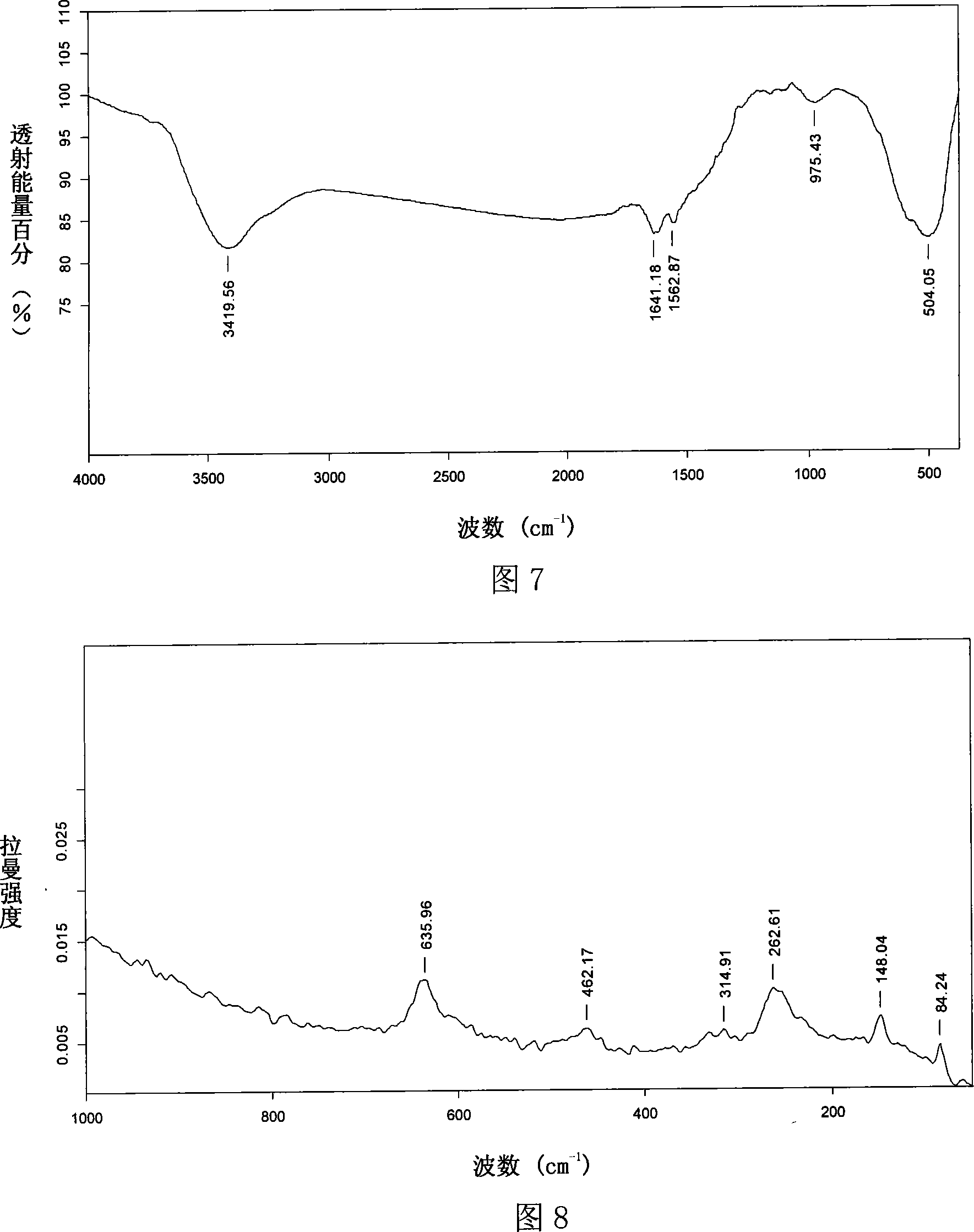

[0042] The granulated powder material was sintered in a muffle furnace at 650°C for 4h. Th...

Embodiment 2

[0045] Take 100kg of zirconium carbonate and 7.61kg of yttrium carbonate crystal powder, add 2000kg of deionized water, and stir evenly to obtain a uniform solution. Add 900kg of ammonia solution with a concentration of 5wt.% to the solution, co-precipitate to obtain a gel and perform 2h aging treatment, and obtain about 390kg of stable gel after filtration and washing.

[0046] According to the weight ratio of 1:1, 390 kg of absolute ethanol was added, and after stirring ball milling for 2 hours and ultrasonic dispersion for 2 hours, a uniform and stable slurry was obtained.

[0047] The uniform and stable gel slurry is spray-dried and granulated by centrifugal spray drying. The inlet temperature is 330°C, the outlet temperature is 170°C, the rotational speed of the centrifugal atomizing disc is 9000r / min, and the cyclone separator is used to collect the granulated product. powder material.

[0048] The granulated powder material is subjected to high-temperature rapid sinter...

Embodiment 3

[0051] Take 100kg of zirconium nitrate and 1.9kg of yttrium nitrate crystal powder, add 2000kg of deionized water, and stir evenly to obtain a uniform solution. Add 600kg of ammonia solution with a concentration of 5wt.% to the solution, co-precipitate to obtain a gel and perform 2h aging treatment, and obtain about 330kg of a stable gel after filtration and washing.

[0052] According to the weight ratio of 1:1, add 330kg deionized water, 30ml ethylene glycol 600 or ethylene glycol 800, 2000ml PVA or CMC, after stirring ball milling for 3 hours, and ultrasonic dispersion for 1 hour, a uniform and stable slurry is obtained.

[0053] The uniform and stable gel slurry is spray-dried and granulated by centrifugal spray drying. The inlet temperature is 330°C, the outlet temperature is 170°C, the rotational speed of the centrifugal atomizing disc is 9000r / min, and the cyclone separator is used to collect the granulated product. powder material.

[0054] The granulated powder mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com