Polymethyl methacryate and carbon nano-tube compound material electric pole and method for making same

A polymethyl methacrylate and carbon nanotube technology, which is applied in the field of polymethyl methacrylate/carbon nanotube composite material electrodes and the preparation thereof, can solve the problem of the peeling off of the carbon nanotube modified layer and the peeling off of the carbon nanotube modified film , poor signal reproducibility and other problems, to achieve the effect of improving stability and mechanical strength, improving reproducibility, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further describe the present invention below by embodiment and accompanying drawing:

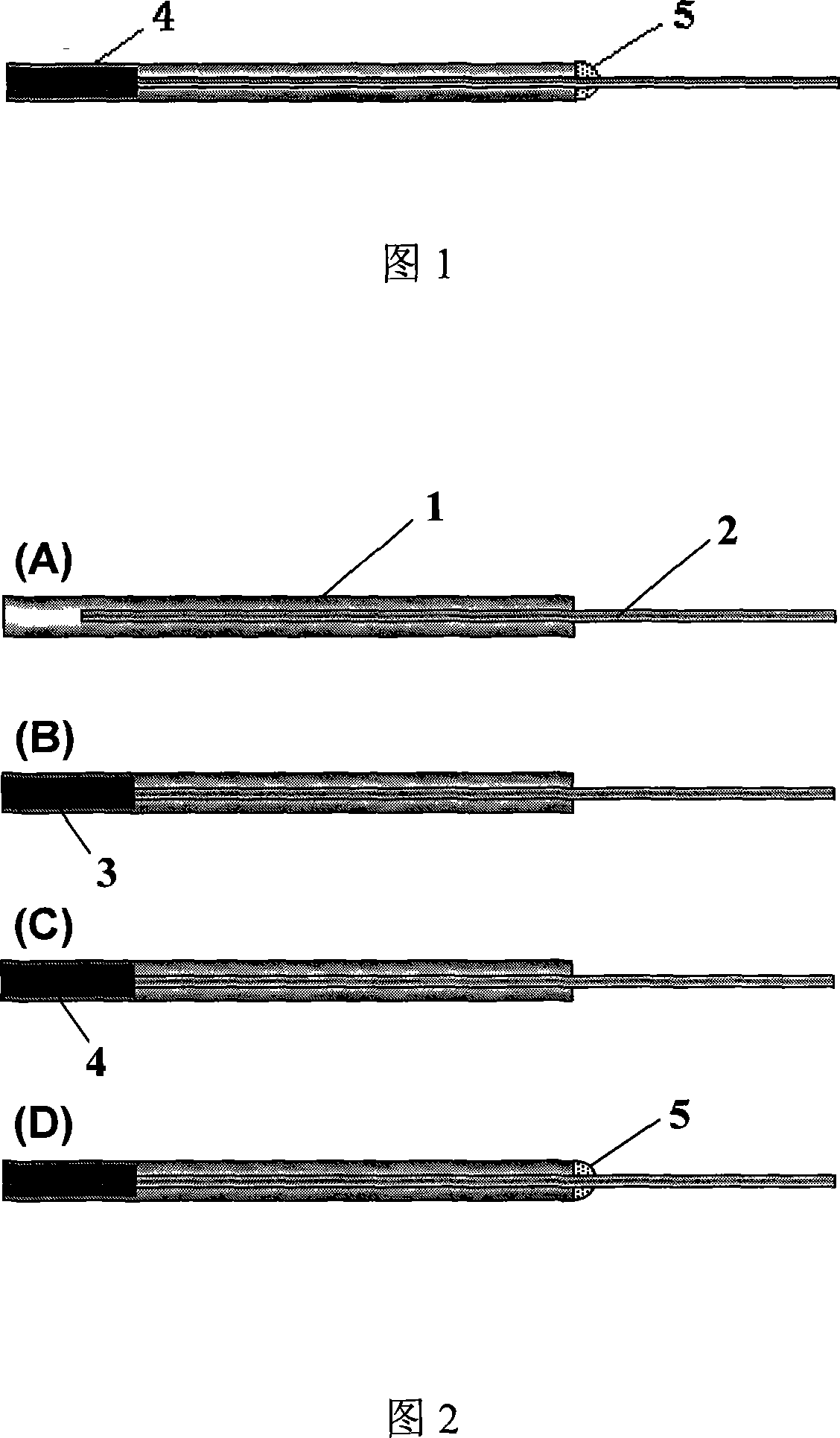

[0021] 1. Preparation of polymethyl methacrylate / carbon nanotube composite electrode for microfluidic chip detection

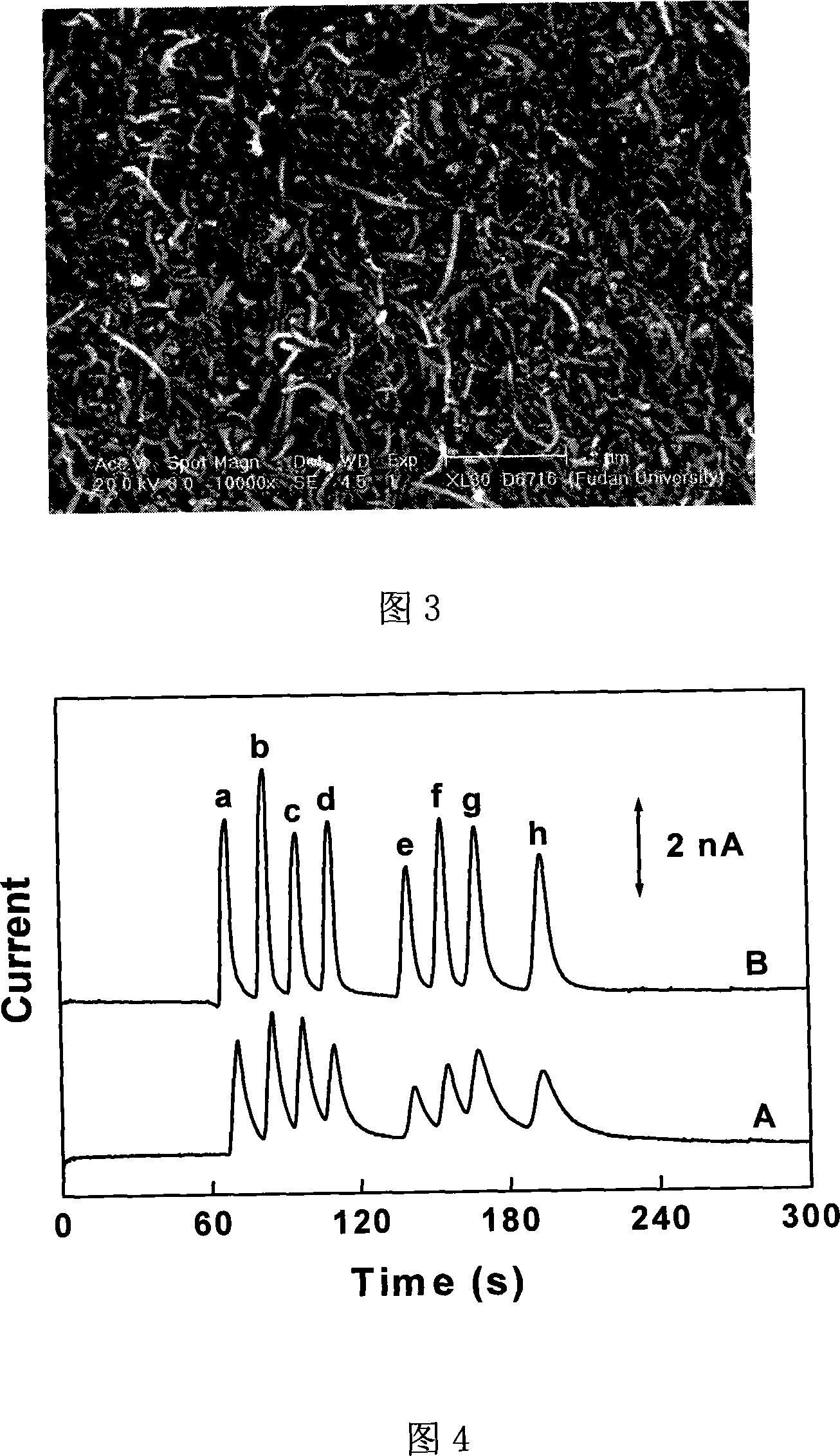

[0022] Mix the monomer methyl methacrylate with a small amount of thermal initiator azobisisobutyronitrile (0.2% of the monomer mass), heat it in a water bath at 50°C to dissolve it, and then heat it in a water bath at 85°C for 15 minutes, every 3 Shake the mixed solution once every minute to prepolymerize the monomer solution into a glycerol-like viscous clear solution. The solution is evenly mixed with carbon nanotubes, wherein the mass percentage of carbon nanotubes is 40%. Since the separation microfluidic channel of the microfluidic chip is small in size and generally has a width of tens of microns, the polymethyl methacrylate / carbon nanotube composite microelectrode can be matched with it. Insert the fused silica capillary (outer diameter 400-500 microns, inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com