Mounting structure of electronic component

A technology for electronic components and mounting structures, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., which can solve the problems of high cost, complex formation of insulating covering film 55, large insulating substrate 51, etc., and achieve narrow width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

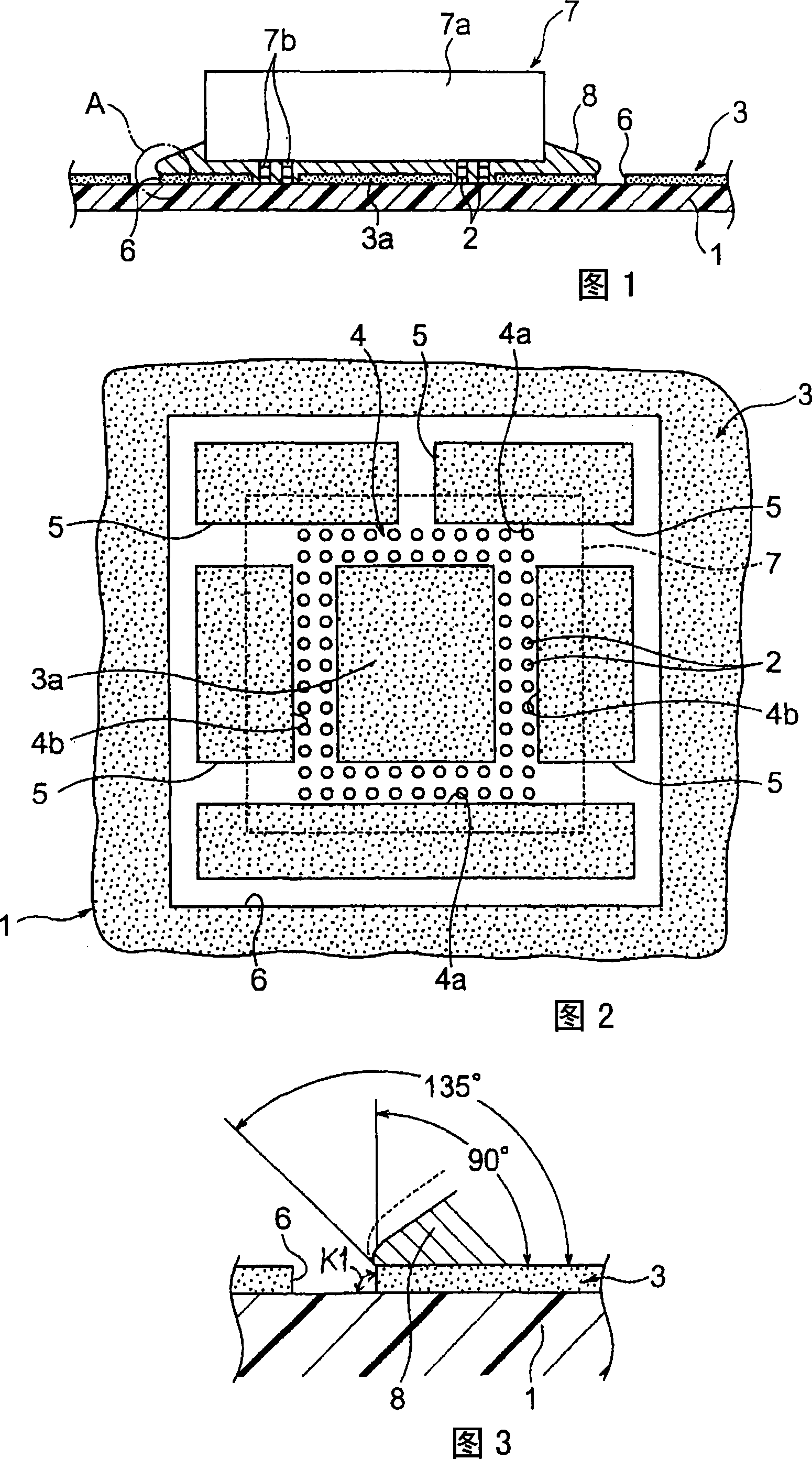

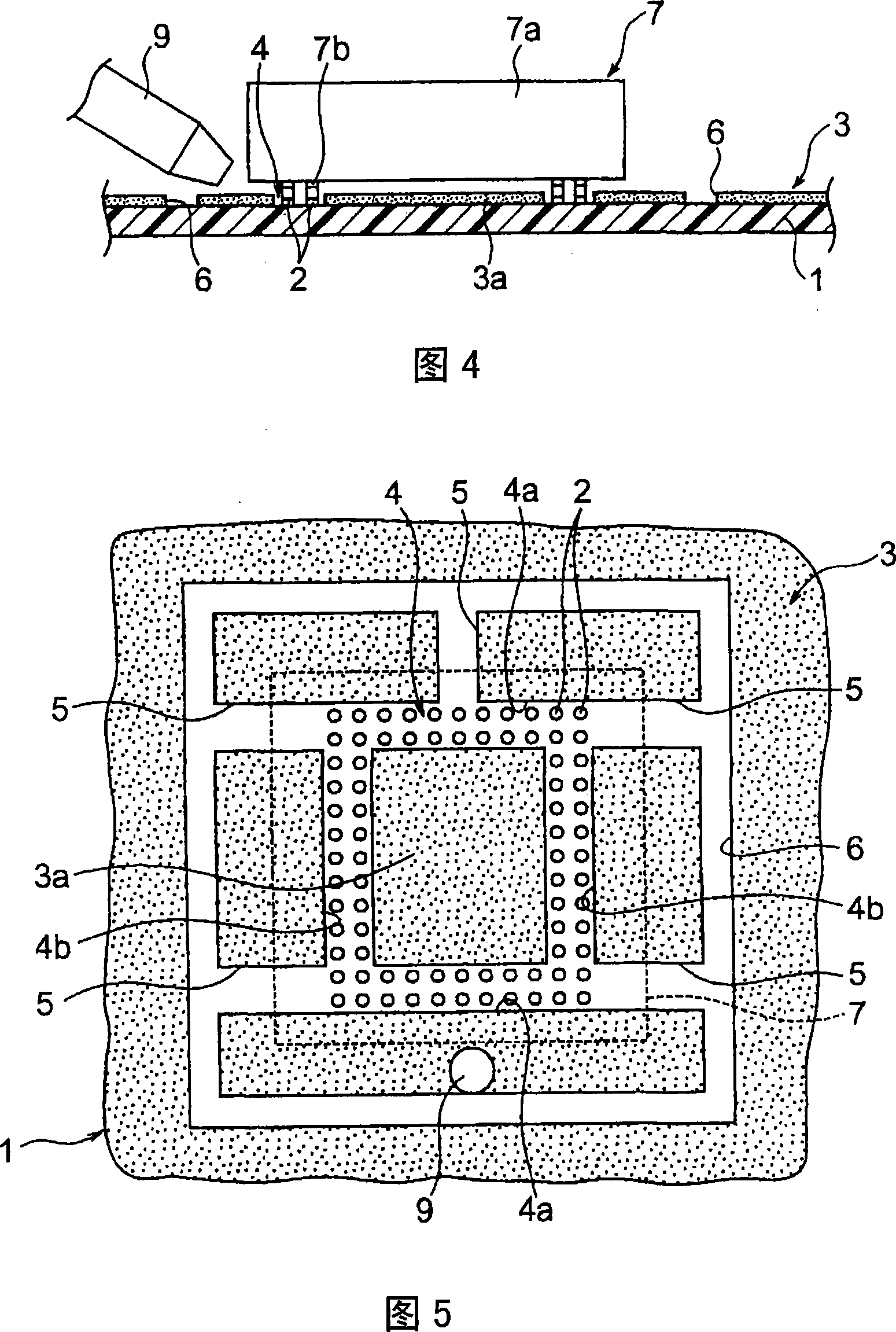

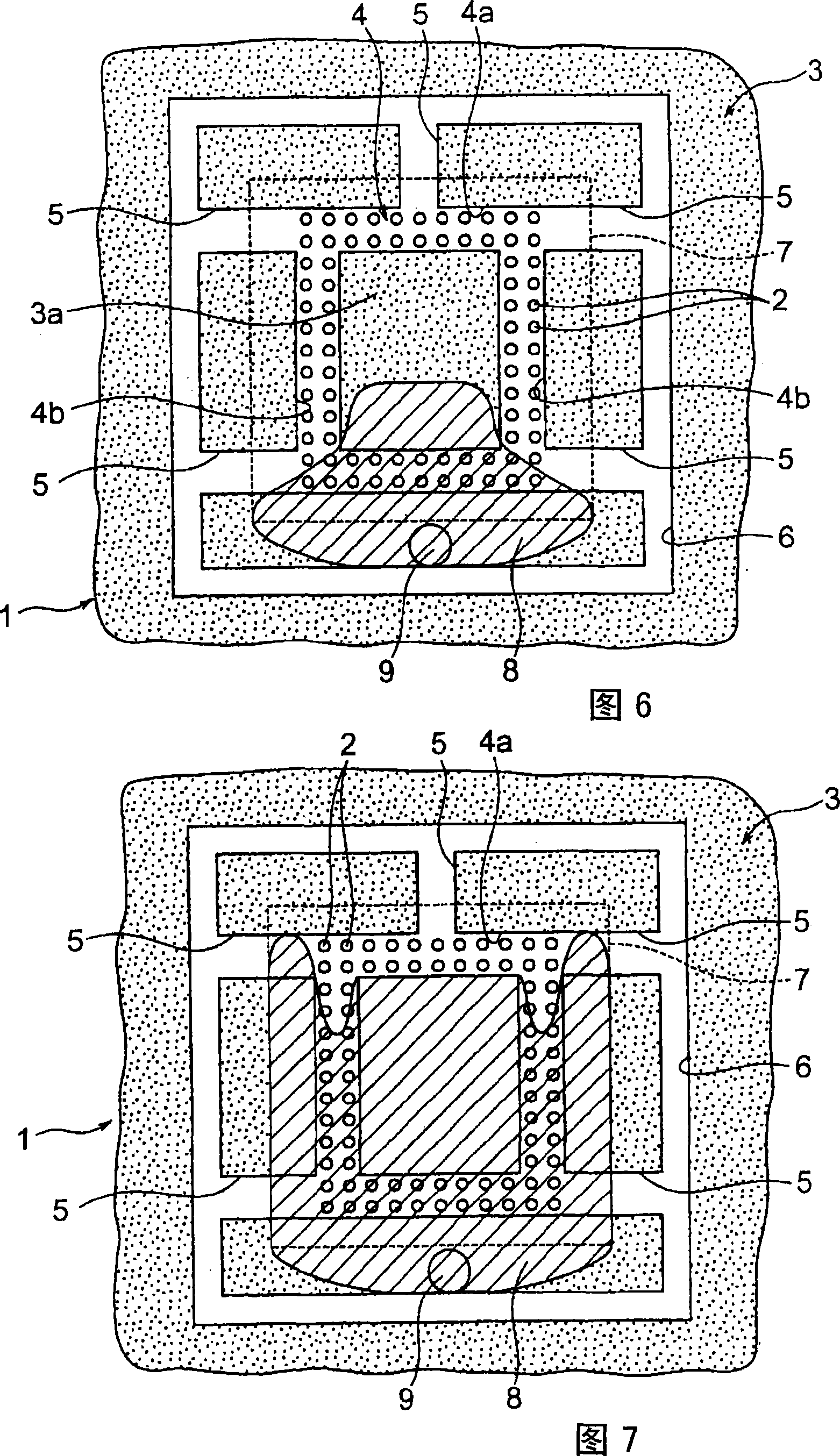

[0032] Hereinafter, embodiments of the invention will be described with reference to the drawings. 1 is a cross-sectional view of a main part of a mounting structure of an electronic component according to the present invention, FIG. 2 is a plan view of an insulating substrate of the mounting structure of an electronic component according to the present invention, FIG. 3 is an enlarged view of part A of FIG. 1 , and FIG. 4 It is a front view showing the mounting method of the electronic component of the present invention, FIG. 5 is a plan view showing the mounting method of the electronic component of the present invention, and FIG. 6 relates to the mounting method of the electronic component of the present invention and shows a liquid underfill In the explanatory diagram of the first flow state of the glue, FIG. 7 relates to the mounting method of the electronic component of the present invention, and is an explanatory diagram showing the second flow state of the liquid underf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com