Quartz products and heat treatment apparatus

A product and quartz technology, which is applied in the field of quartz products and heat treatment devices, can solve the problems such as the inability to effectively prevent wafer contamination, and achieve the effects of reducing copper contamination and inhibiting the reduction of yield

Inactive Publication Date: 2007-12-26

TOKYO ELECTRON LTD

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, only the number of atoms on the surface of the quartz product is used to evaluate the copper contamination of the quartz product, which cannot effectively prevent the contamination of the wafer.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0050] Next, the results of carrying out the specific baking method for obtaining quartz products according to the present invention will be described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to control of copper contamination to semiconductor substrates upon operation of a heat treatment apparatus which is a semiconductor manufacturing apparatus and which is constructed with quartz products having been contaminated with copper when machined. The quartz product is placed in a heating atmosphere on the stage where it is not still used for a heat treatment for semiconductor substrates. Baking gases including a hydrogen chloride gas and a gas for enhancing activity of the hydrogen chloride gas, for example, an oxygen gas, are then supplied to the quartz product. Consequently, the copper concentration in the region from the surface to the 30 mum depth of the quartz product can be controlled below 20 ppb, preferably below 3 ppb. The baking process may be carried out before or after assembling the quartz product into the heat treatment apparatus.

Description

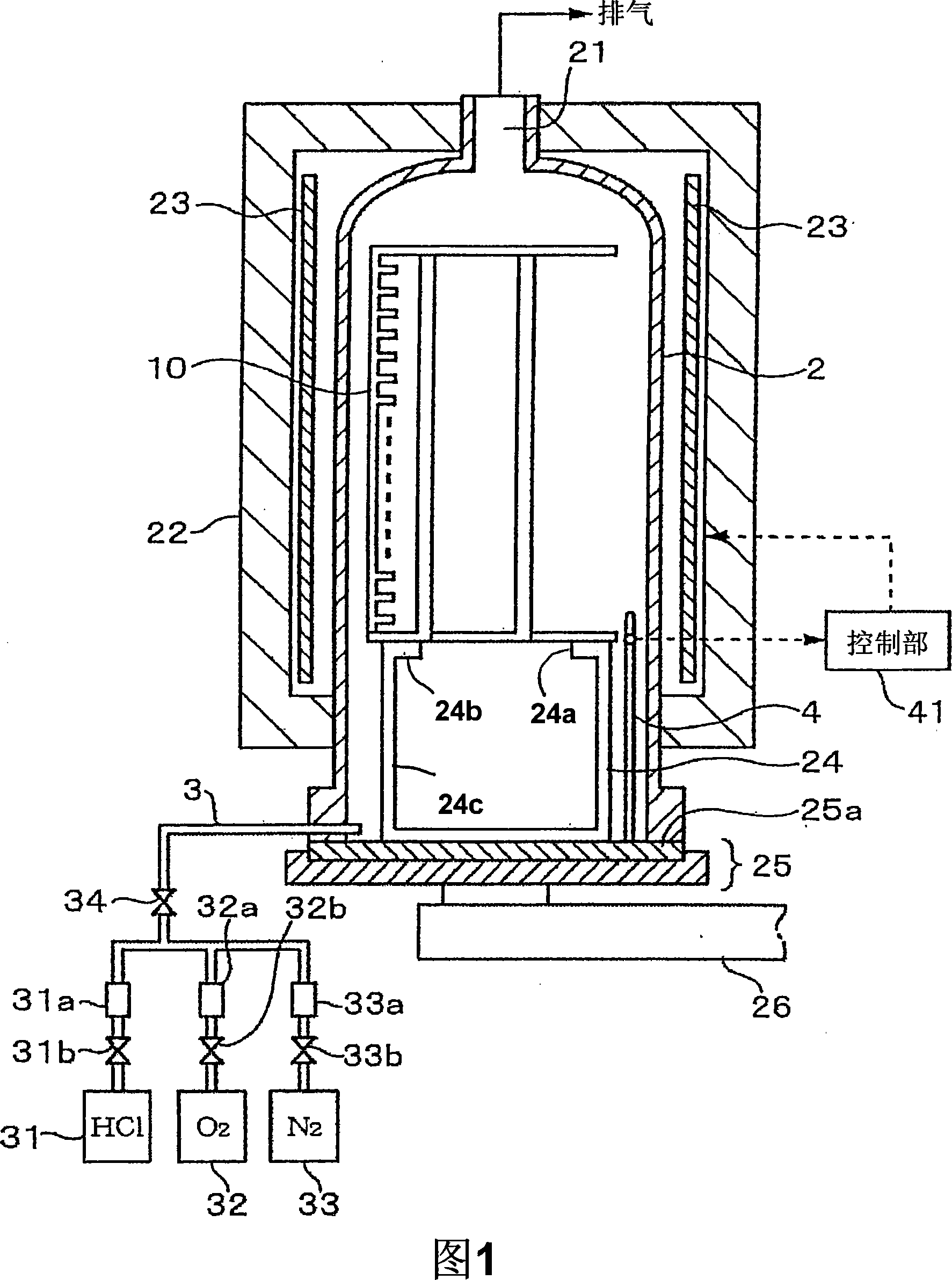

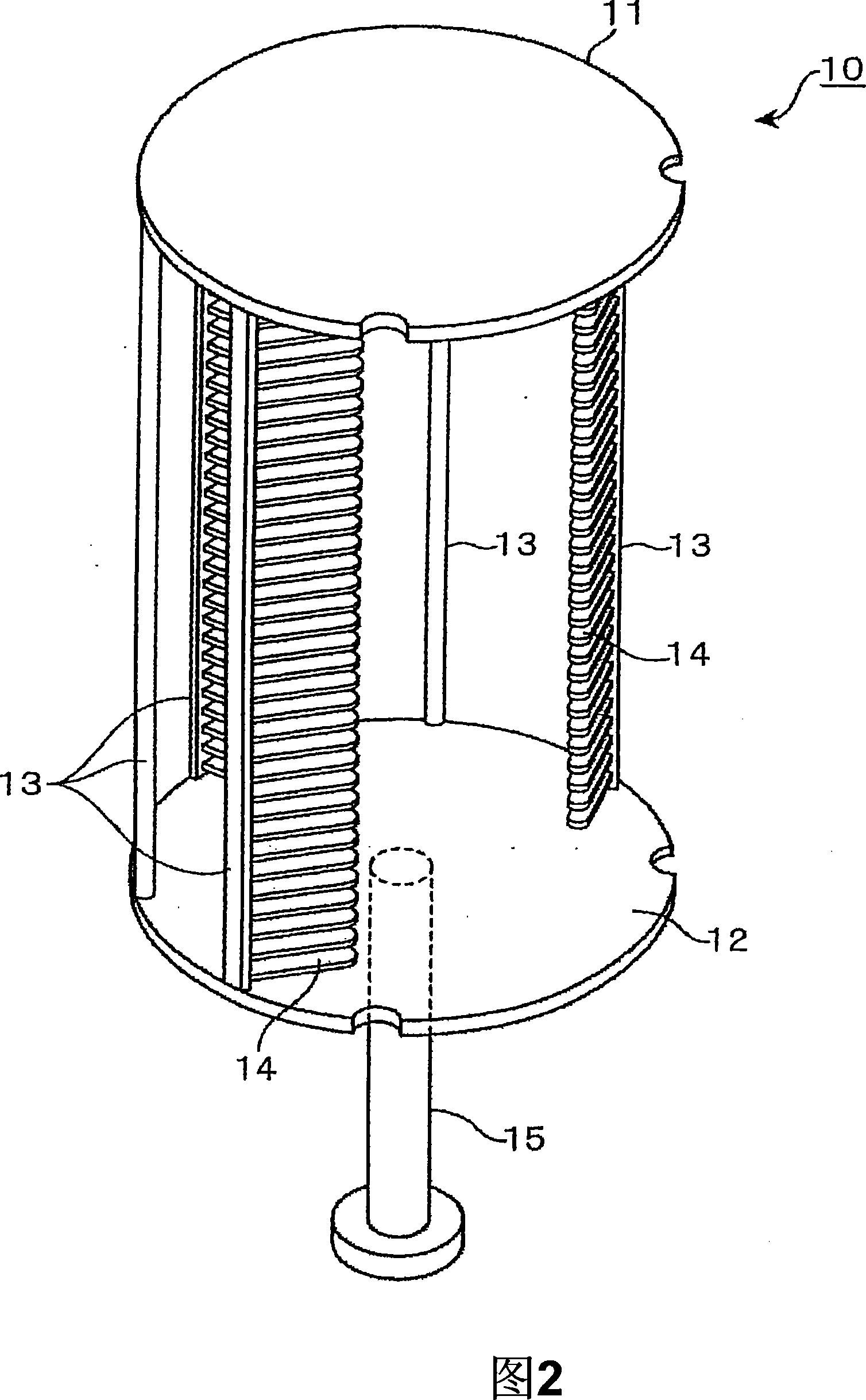

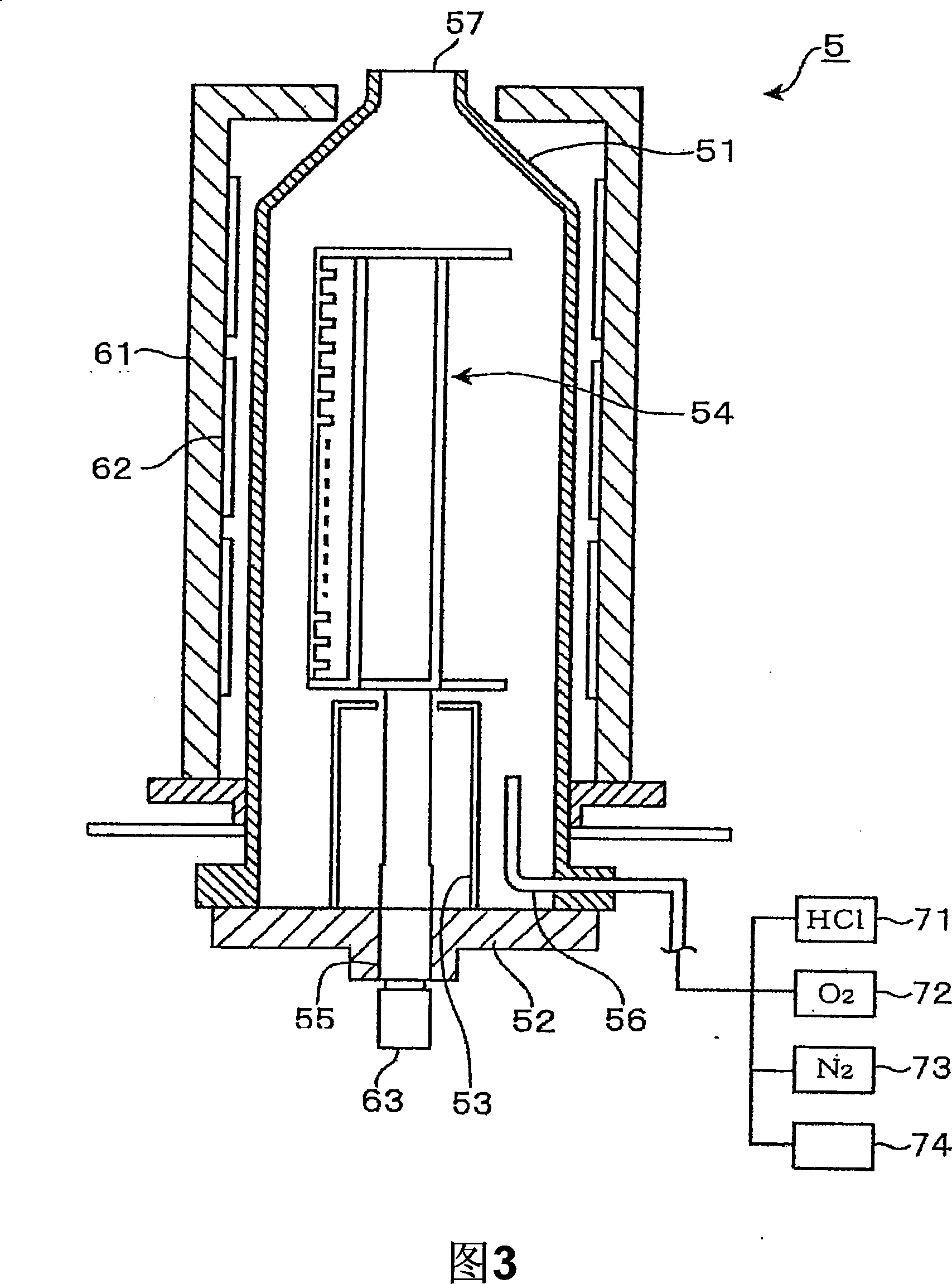

technical field [0001] The present invention relates to a technique for removing metal contained in a quartz product by baking the quartz product as a component of a heat treatment apparatus for heat-treating a semiconductor substrate. Background technique [0002] As one of the heat treatment equipment used in the semiconductor manufacturing process, there is a vertical heat treatment equipment which is a batch type heat treatment equipment. This vertical heat treatment apparatus includes a heating furnace having a vertical reaction tube opened at the bottom and a heat source provided so as to surround the outside of the reaction tube. A plurality of semiconductor wafers (hereinafter referred to as wafers) are held in a wafer holder called a wafer boat in the shape of a partition, and are carried in from the lower side of the reaction tube, and are subjected to oxidation treatment, diffusion treatment, or formation by CVD in the reaction tube. Membrane treatment etc. [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B20/00

CPCC23C16/4404C23C16/4581H01L21/324H01L21/67098H01L21/67306

Inventor 安倍胜彦及川雅之柴田哲弥谷裕一

Owner TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com