Anti-deforming arrangement of reinforcing wire case tension bourette

An anti-deformation and steel wire technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of response relationship lag, plastic deformation, elongation, etc., to improve the pass rate and aesthetics, deformation The effect of reducing the situation and increasing the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments.

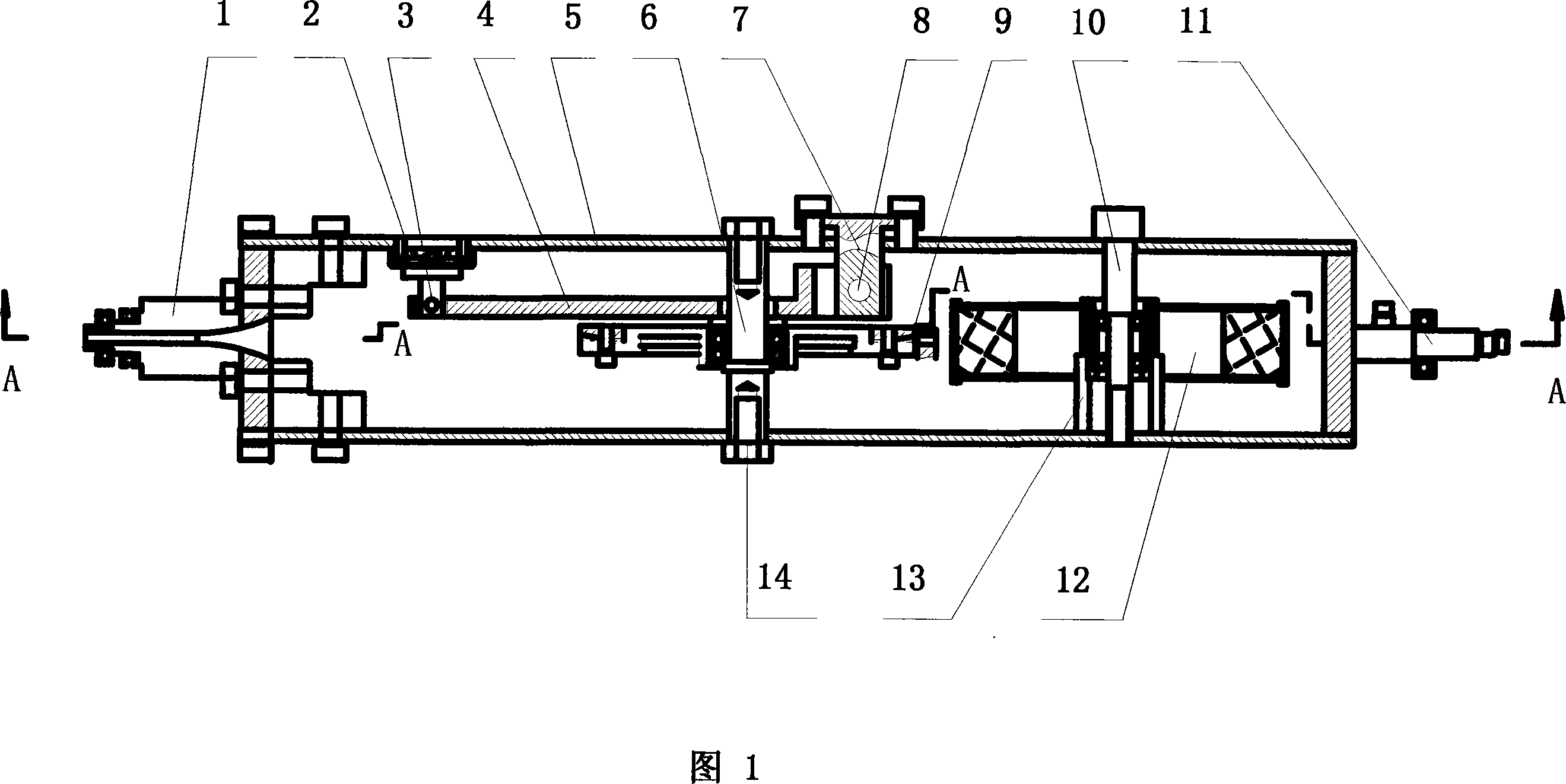

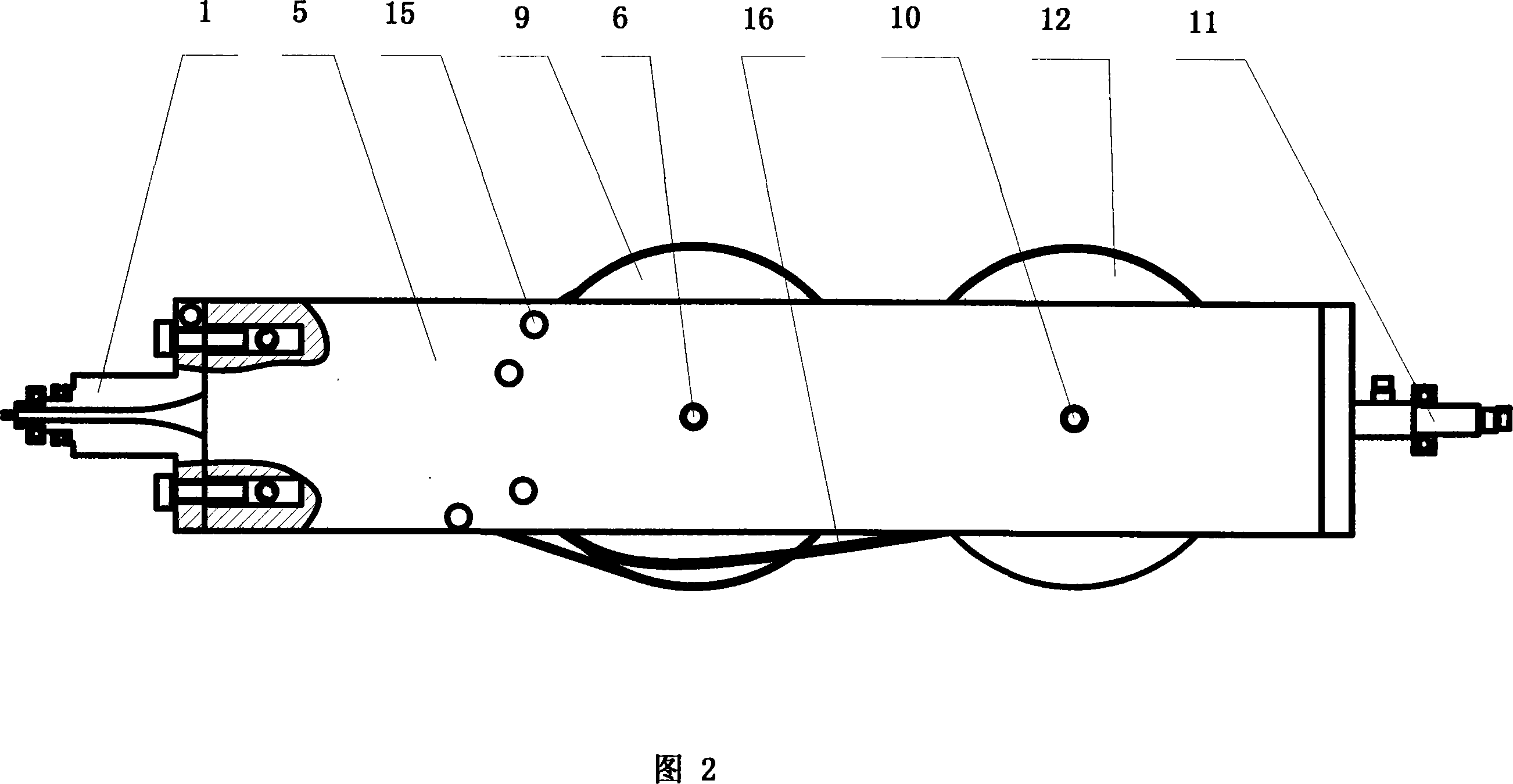

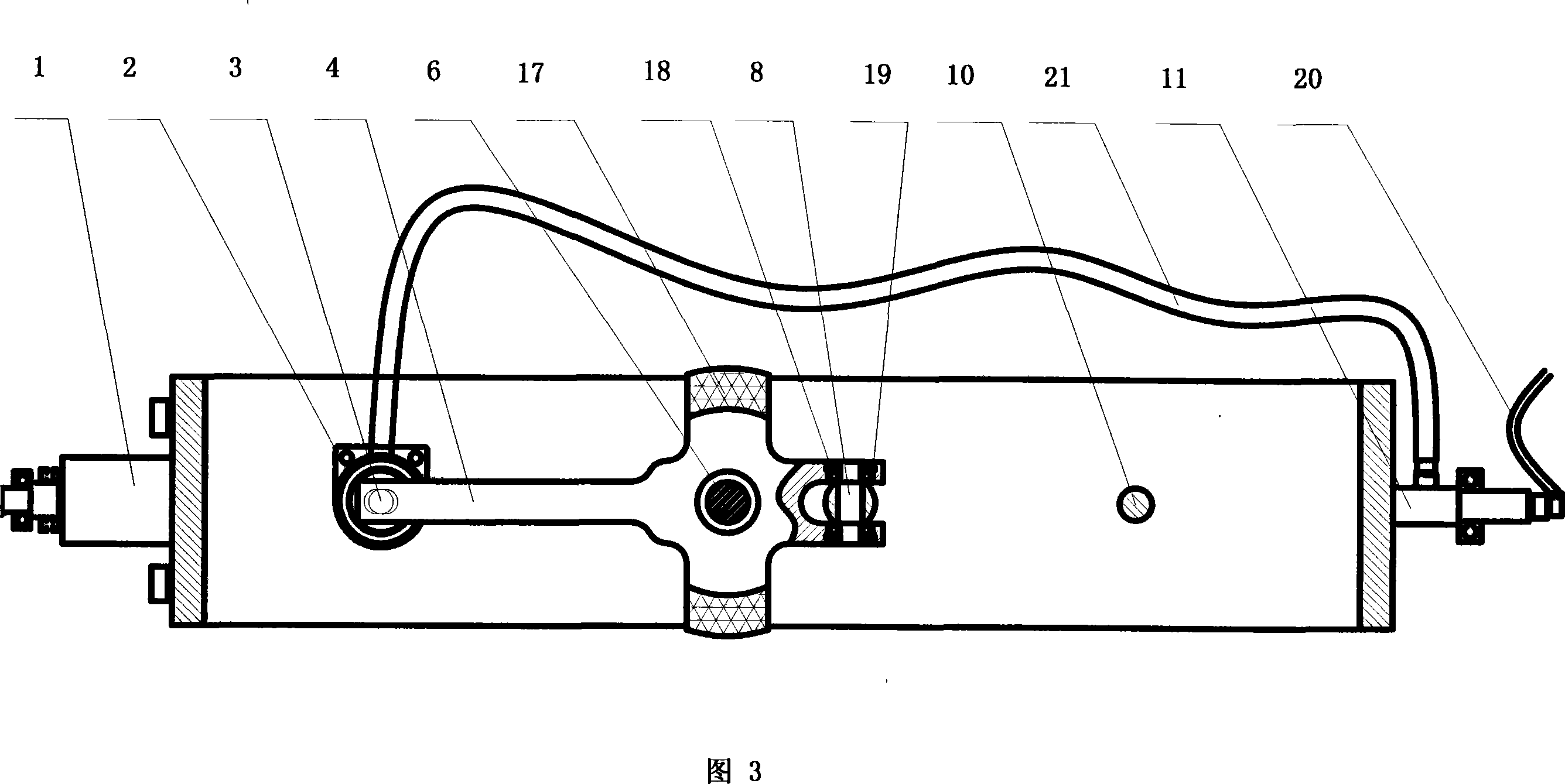

[0020]As shown in Figures 1 to 3, an anti-deformation device for wire box tension drawing mainly includes a compressed air delivery system, a resistance drawing system, a steel wire winding system, a steel wire traction guide part 1 and a steel wire box 5, etc. The compressed air conveying system is made up of intake pipe 20 , rotary joint 11 and air delivery pipe 21 . The resistance spinning system is mainly composed of cylinder 2, push rod 3, brake pad lever 4, friction plate 17, base 7, resistance disc shaft 6 and resistance disc 9. The wire winding system is mainly composed of a winding reel 12, a reel shaft 10 and a wire positioning pin 15. The steel wire traction guide part 1 is affixed to one end of the steel wire box 5 with a fastening screw, and the rotary joint 11 of the compressed air delivery system is fastened to the other end of the steel wire box 5 by thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com