Tubing pump deivce

A technology of tube pumps and limit devices, which is applied in pumps, liquid variable displacement machines, pumps with flexible working elements, etc., can solve problems such as cracks and cracks, and achieve the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described with reference to the drawings.

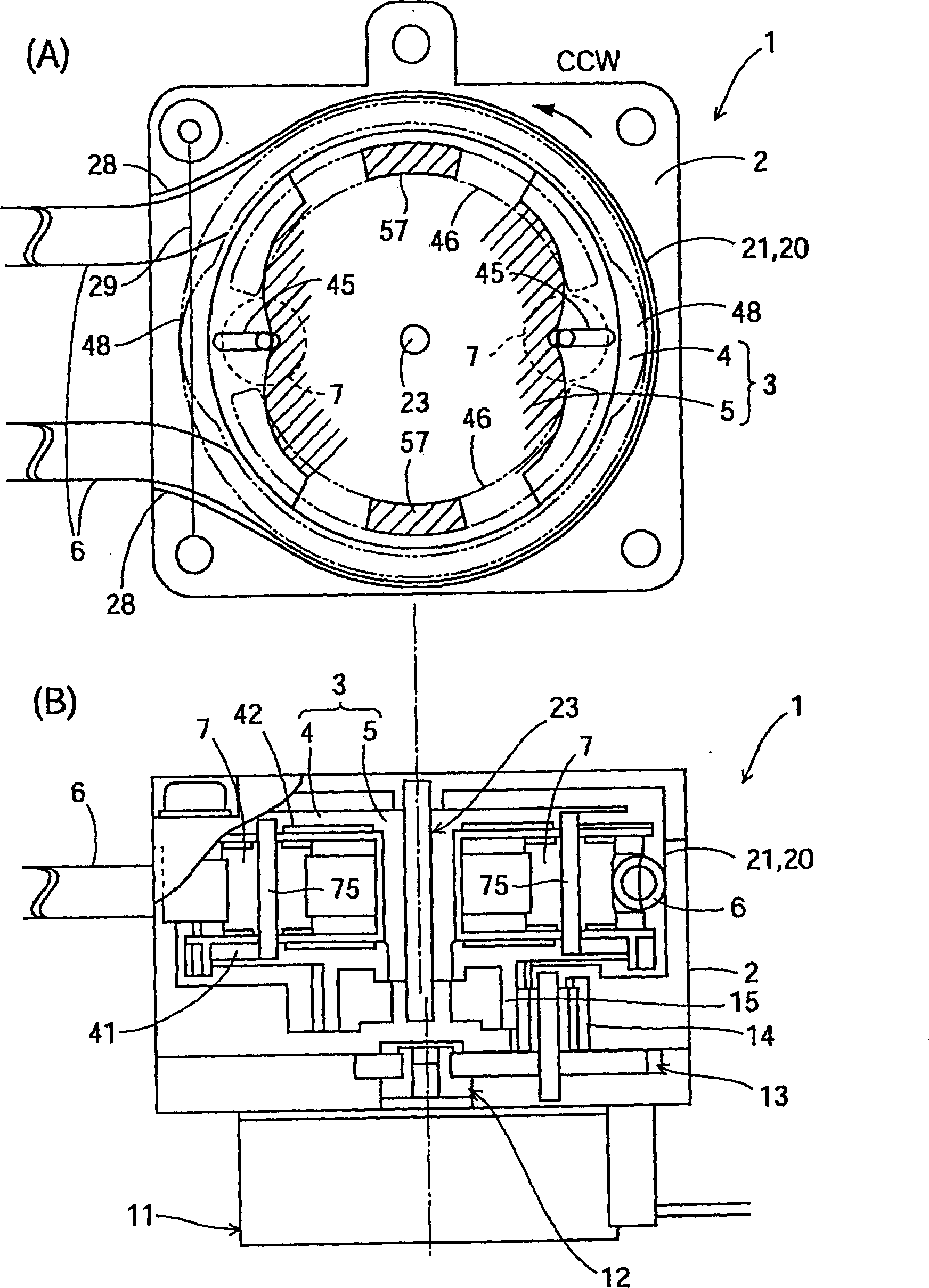

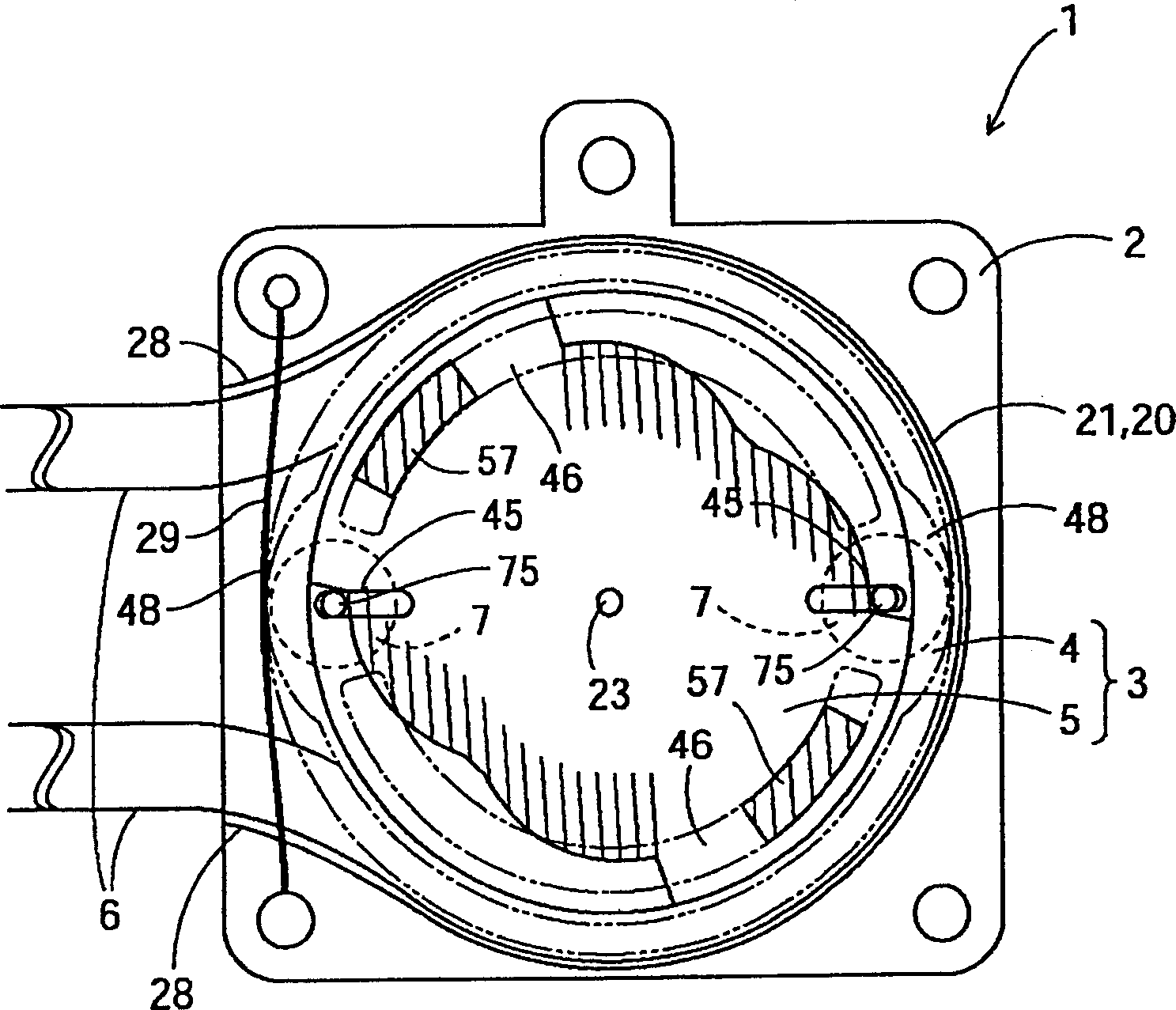

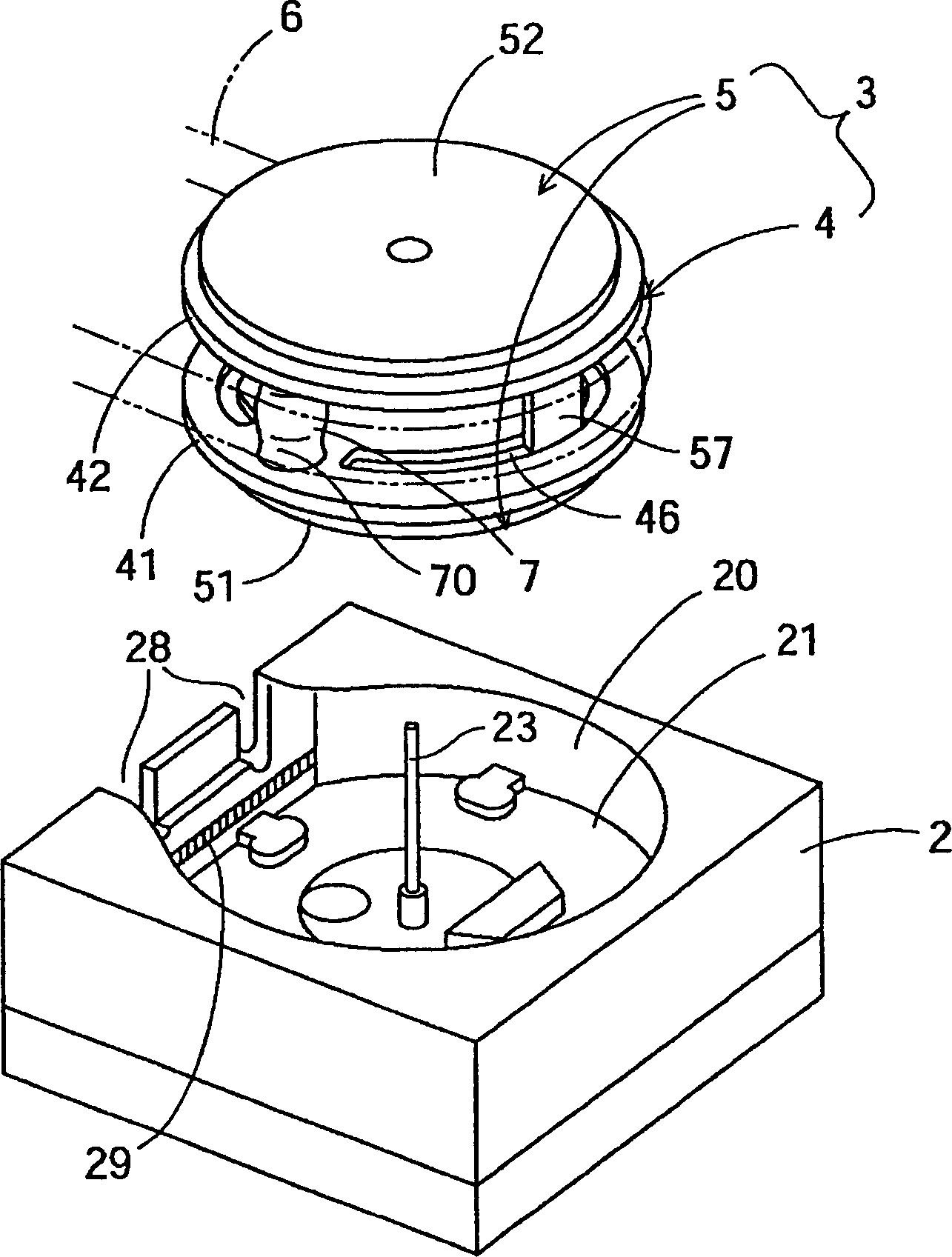

[0027] figure 1 (A) and (B) are explanatory plan views showing main parts of a tube pump device in an applied form and a cross-sectional view of the pump device. figure 2 From figure 1 An explanatory diagram of the timing at which liquid delivery starts in the state shown in (A). image 3 It is a perspective view which shows the state which disassembled the tube type pump apparatus of this form into a casing and a rotating body. Figure 4 (A) and (B) represent the image 3 The shown rotating body is disassembled into a perspective view of a roller support body, a pair of end plates, and rollers for crushing a pipe, and a perspective view of a pair of support plates viewed from obliquely below the lower support plate. Figure 5 (A), (B), and (C) are a plan view, an A-A' sectional view, and a bottom view of the roller support, respectively. Image 6 (A) and (B) are the front vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com