Method for preparing chitin/chitosan from rind and shell of silkworm chrysalis and fly maggot

A chitin and chitosan technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low quality of chitin products, difficulty in preparing chitin, and excessive fat in the skin , to achieve beneficial quality control, excellent stability, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

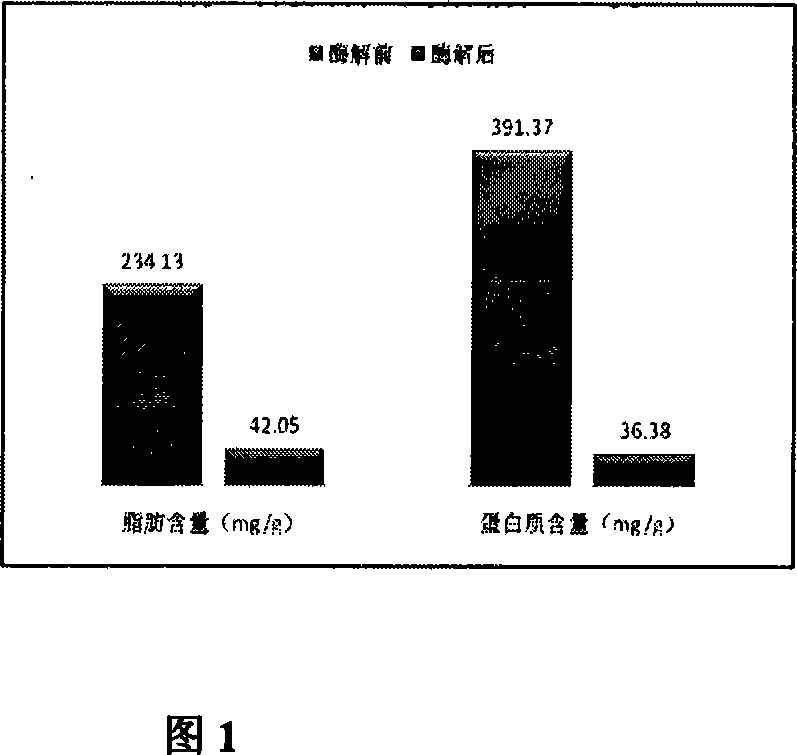

[0060] Embodiment 1: the preparation of silkworm chrysalis chitin

[0061] a. Pretreatment: Collect 10kg of fresh silkworm chrysalis, wash and remove impurities, fully drain, and then use a meat grinder to mechanically break the skin, squeeze out the contents with a pressing method (hydraulic or screw press) (to be processed separately), and collect the skin The shells are dried until the water content is less than 10%, and pre-frozen at below 0°C for 6 hours. After agglomeration, the shells are crushed to a fine powder with an average particle size of 150-250 μm (60-100 mesh) with a centrifugal impact crusher.

[0062] b. The obtained fine powder is first soaked in hot water at 65°C for 30 minutes, poured out, and then mixed with clean warm water at 40°C and an equal volume of lipase and protease at a ratio of solid:liquid=1:4. Enzyme solution, at a constant temperature of 40°C, slowly mix the leather shell fine powder and crude enzyme solution in a reaction kettle, and carry...

Embodiment 2

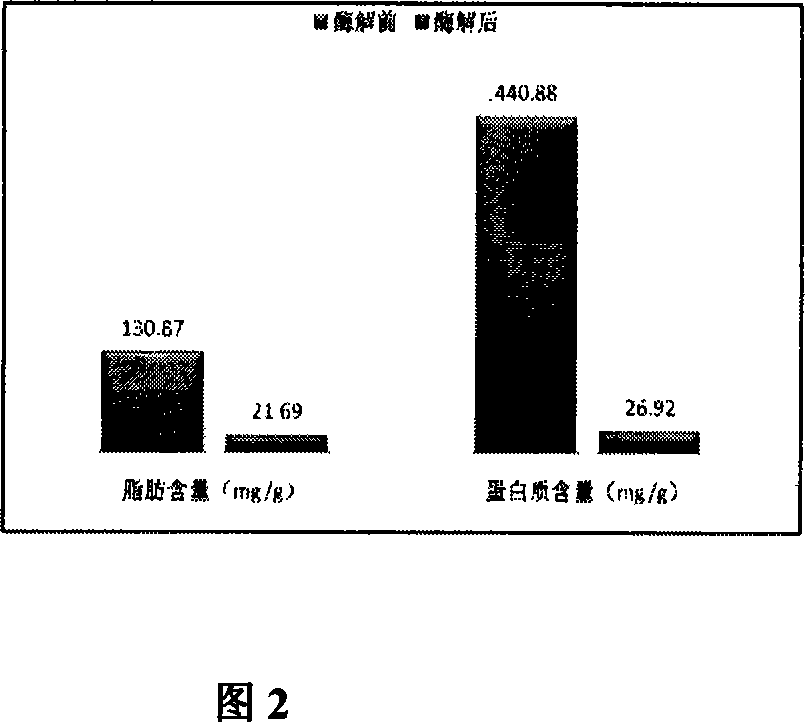

[0065] Embodiment 2: the preparation of fly maggot chitosan

[0066] a. Pretreatment: collect 10kg of fresh fly maggots, wash and remove impurities, fully drain, and then use a meat grinder to mechanically break the skin, squeeze out the contents with a pressing method (hydraulic or screw press) (to be processed separately), and collect the skin The shells are dried until the moisture content is less than 10%, pre-frozen at below 0°C for 6 hours, and after hardening, crush them with a centrifugal impact mill to a fine powder with an average particle size of 150-250 μm (60-100 mesh).

[0067] b. The obtained fine powder is first soaked in hot water at 65°C for 30 minutes, poured out, and then mixed with clean warm water at 40°C and an equal volume of lipase and protease at a ratio of solid:liquid=1:4. Enzyme solution, at a constant temperature of 40°C, slowly mix the leather shell fine powder and crude enzyme solution in a reaction kettle, and carry out a co-enzyme hydrolysis d...

Embodiment 3

[0072] Embodiment 3: Lactobacillus fermentation prepares chitooligosaccharides

[0073] a. Pretreatment: 10 kg of silkworm pupae are cleaned and removed, and the skin is broken, and the content is extruded by pressing, and the skin is collected, dried until the moisture content is less than 10%. It is crushed to a fine powder with an average particle size of 150-250 μm (60-100 mesh).

[0074] b. Soak the fine powder in hot water at 65°C for 30 minutes, pour it off, then add clean warm water at 40°C and an equal volume of lipase and protease mixed crude enzyme solution at a ratio of solid:liquid=1:4 , at a constant temperature of 40°C, slowly mix in the reactor, stir intermittently, and perform a co-enzymatic degreasing and deproteinizing reaction. The reaction time is 18 hours. After the reaction is terminated, centrifuge (2500r / min) for solid-liquid separation.

[0075] c. Collect the solid material, wash it three times with warm water at 40°C, drain it, and wash it with 5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com