Amorphous mobile tape-making production process

A production method and mobile technology, applied in the field of amorphous mobile tape production, can solve the problems of difficult control of the production process, long production process and high production cost, and achieve short production process, short production process and high production cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

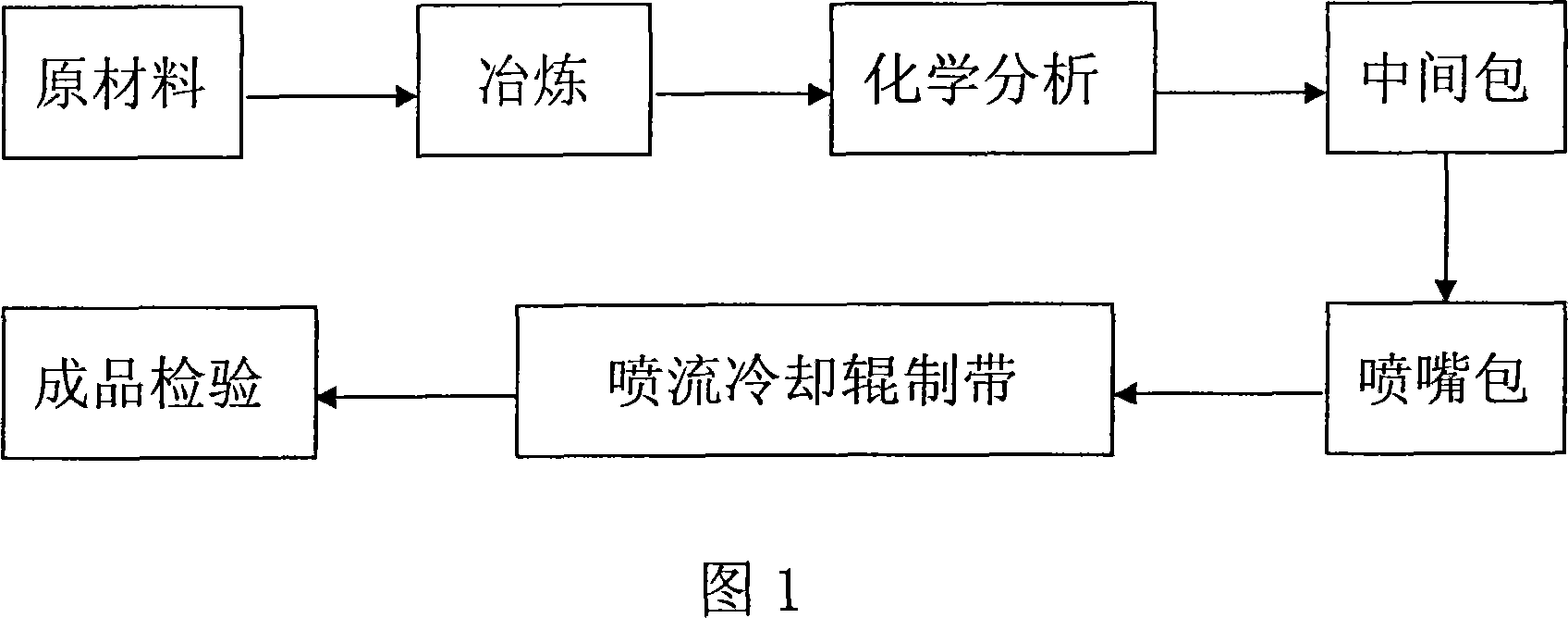

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] The iron-based amorphous raw materials are smelted into alloy ingots, chemically analyzed, and the molten steel is poured into the tundish (about 1300°C), and the molten steel enters the nozzle pack (about 1200°C) from the tundish, and then flows into the high-speed rotating cooling roll from the nozzle pack On, rapidly cooling to form an amorphous thin strip, finished product inspection.

[0010] in,

[0011] 1. The chemical composition of molten steel when tapping is completed by chemical analysis before the furnace. Tapping temperature control is controlled by fast thermocouple.

[0012] 2. The stability of the liquid level of the nozzle package affects the thickness and density of the amorphous strip. The closed-loop control of steel replenishment from the tundish to the nozzle package makes the liquid level of the nozzle package fluctuate at about ±2mm.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com