Dew-point humididier and temperature control for corresponding gas

A technology of humidifier and wet gas, which is applied in the direction of humidity control, control/regulation system, non-electric variable control, etc. It can solve the problems of difficult precise control of humidity and achieve the effect of accurate temperature measurement and thermal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

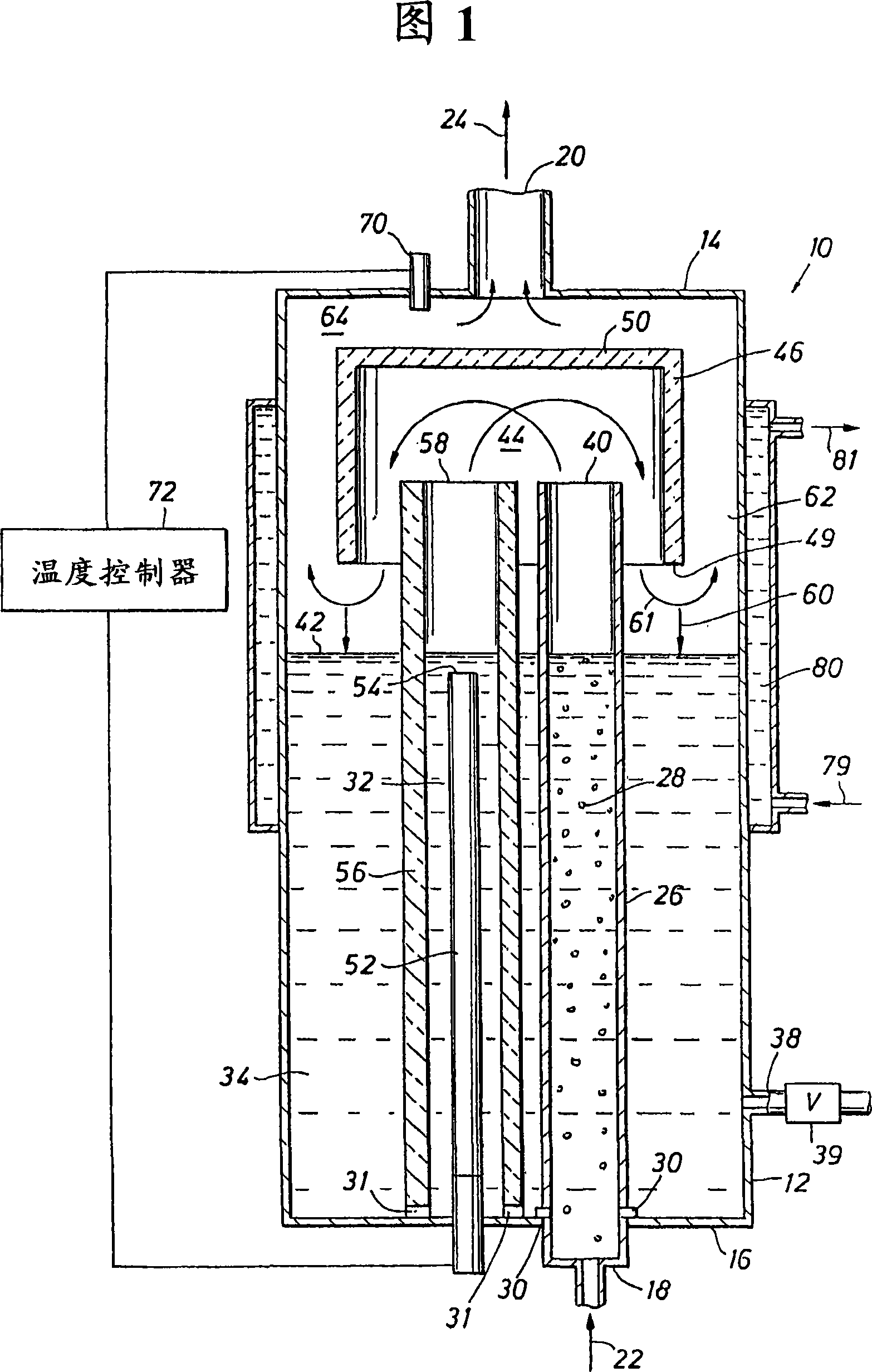

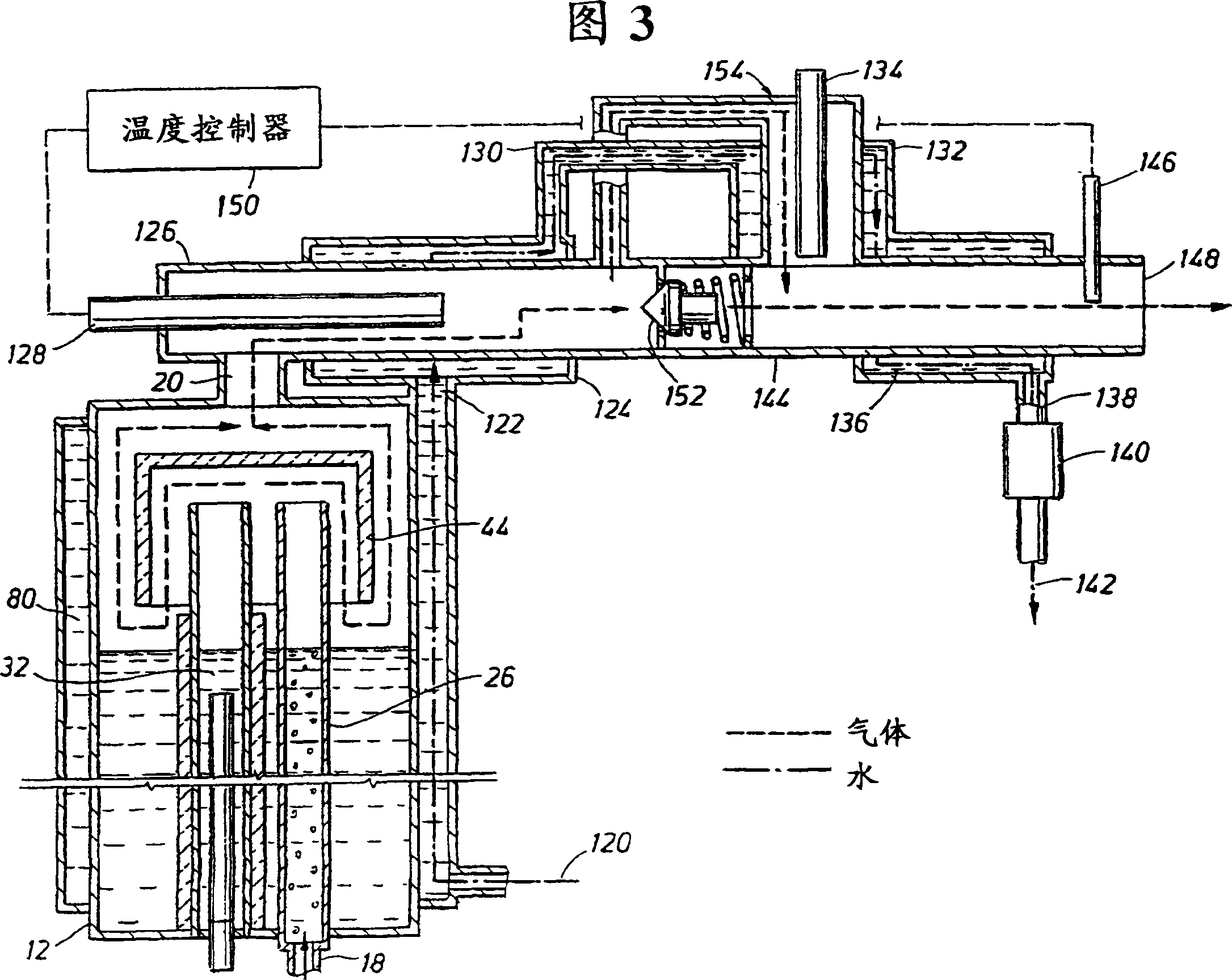

[0031] Figure 1 shows the core structure of a humidifier 10 of the present invention and the method of humidifying gas. Humidifier 10 basically includes a container 12 having a top 14 and a bottom 16, which is preferably cylindrical. Inlet line 18 introduces drying gas into vessel 12 and outlet 20 directs humidified gas from the vessel. The entry of drying gas into the container is shown by arrow 22 and the exit of humidified gas from the container is shown by arrow 24 .

[0032] The drying gas 22 having a temperature below the set dew point temperature begins to be humidified by passing through the pre-humidifier 26 . The dry gas 22 is bubbled through the pre-humidifier 26 to form water bubbles 28, which rise through the pre-humidifier, picking up some moisture and being heated to a higher temperature by the water in the pre-humidifier column. The pre-humidifier 26 is formed as an elongated container such as a tube with an opening 30 preferably along the bottom of the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com