A device for retaining molten matter outside the nuclear power plant after an accident

A technology for core melt and nuclear power plants, applied in nuclear power generation, emergency protection devices, nuclear engineering, etc., can solve problems such as IVR powerlessness, and achieve the effects of improving high safety, preventing a large amount of radioactivity from leaking, and preventing direct heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

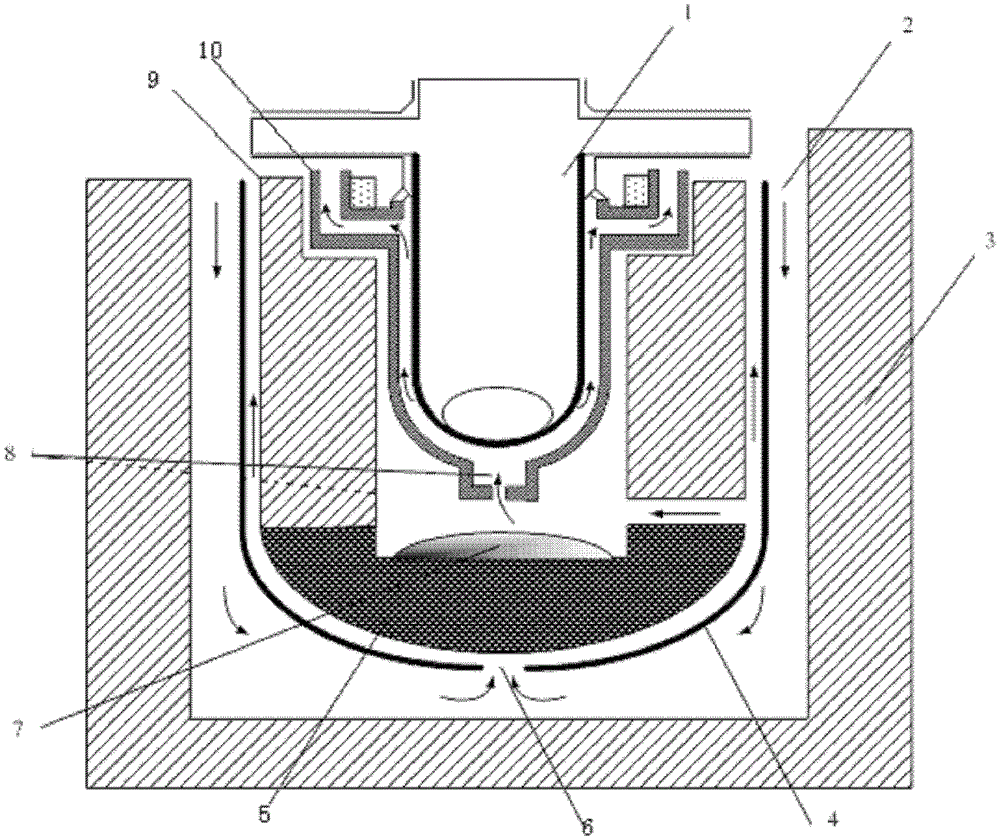

[0019] The present invention includes a pressure vessel 1 , an outer wall 3 , an inner wall 9 , a reactor core melt retention device 5 , and a deflector 4 .

[0020] The inner wall 9 is closed around and open up and down, and the inner side of the inner wall 9 is poured with concrete to fix the steam channel wall 10 with the bottom opening. The pressure vessel 1 is supported by pipes in the vapor channel wall 10 . A steam rising channel 8 is formed between the pressure vessel 1 and the steam channel wall 10 .

[0021] The core melt retention device 5 is fixed on the bottom of the inner wall 9 by pouring concrete. A coolant channel is provided between the inner wall 9 and the core melt retention device 5 . The core melt retention device 5 is composed of inorganic non-metallic refractory materials that can withstand the upper limit temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com