Method for preparing micron/submicron metal ring and open-mouth metal ring

A technology of metal rings and microspheres, applied in chemical instruments and methods, separation methods, microstructure technology, etc., can solve the problems of complex micromachining technology, high cost, and long time consumption of equipment, and achieve low equipment requirements and low cost , good effect of monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

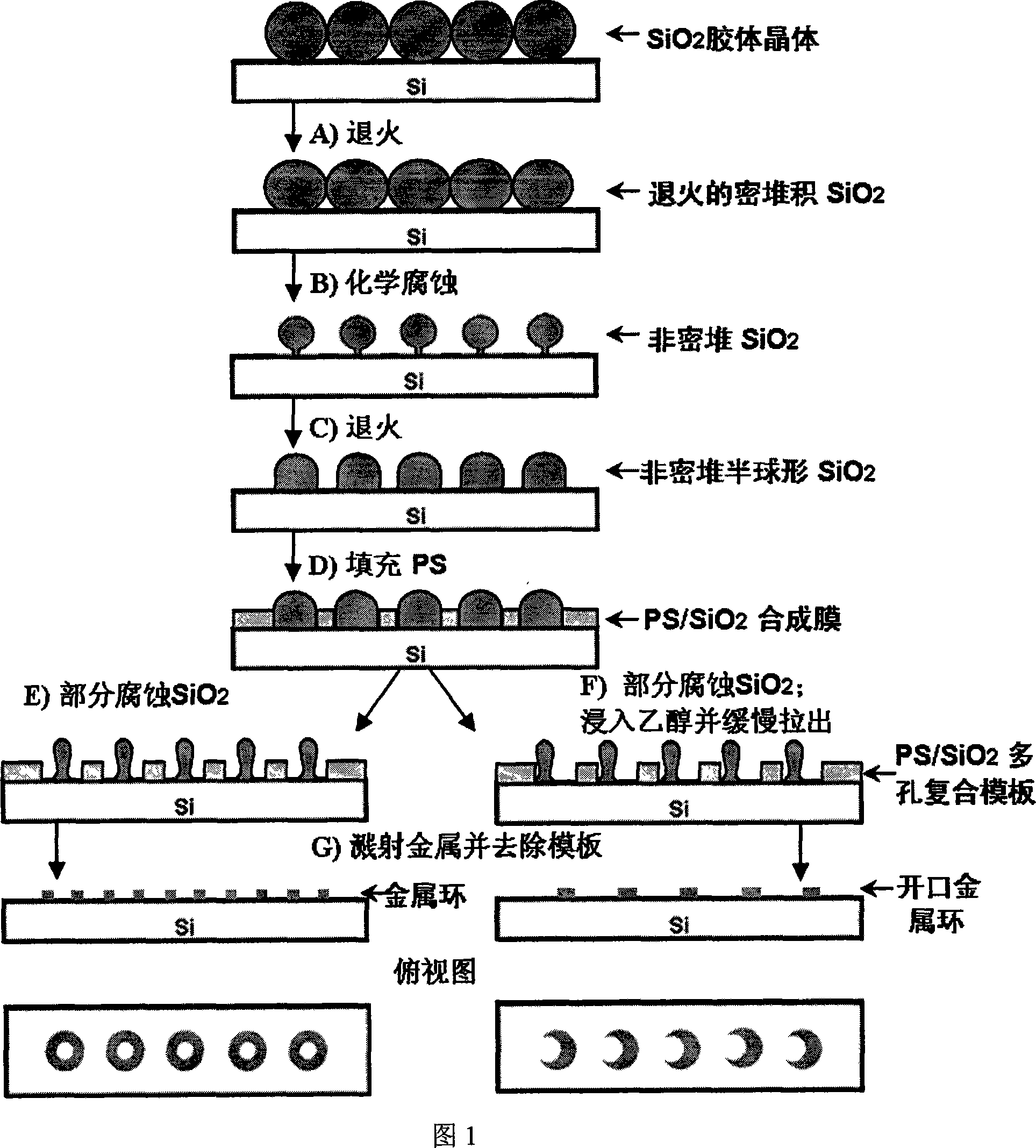

[0018] Example 1: The selected micron / submicron silica microspheres have a diameter of 1550nm (anywhere between 200nm and 10μm), the filled polymer is polystyrene (PS) (or other organic polymers), sputtered metal The material is gold. The preparation method of two-dimensional ordered micron / submicron gold ring is:

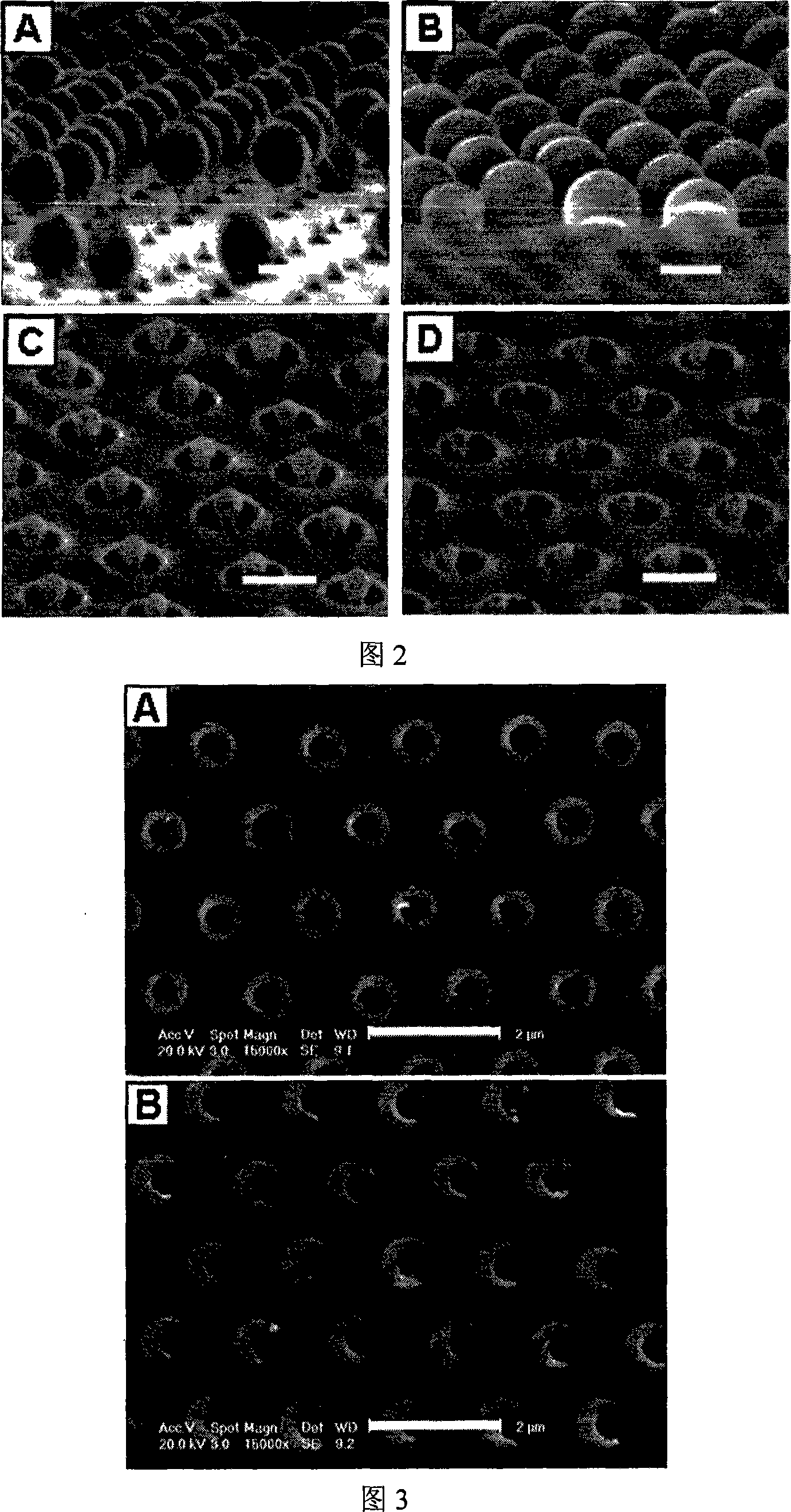

[0019] 1. Non-close-packed hemispherical SiO 2 Preparation of ordered arrays. Aligning SiO on silicon substrates by self-assembly technique 2 , to obtain a large-area highly ordered two-dimensional single-layer microsphere array; then after high-temperature annealing at 1250 ° C for 15 minutes, 40% HF solution steam corrosion for 1 to 3.5 minutes, to obtain non-close-packed SiO 2 Ordered array, see Figure 2(A); then perform a second annealing at 1300°C for 10 minutes to form a non-close-packed hemispherical SiO 2 Ordered array, see Figure 2(B), (the temperature of the high temperature annealing treatment is 1250-1300°C, and the annealing time is within the rang...

Embodiment 2

[0022] Example 2: Preparation of two-dimensional ordered micron / submicron gold split rings: the preparation process is basically the same as in Example 1, but after obtaining PS / SiO 2 After the ring-shaped porous template, it was immersed in alcohol solution, and then the template was slowly taken out by tilting. This process caused the PS porous membrane to move slightly until the boundary of the PS pores touched the SiO in the pores. 2 , thus obtaining the split ring PS / SiO 2 Porous template, see Fig. 2 (D); After sputtering gold on this template and removing template with the method for Example 1, promptly obtain the hexagonal non-close-packed two-dimensional ordered micron / submicron gold open ring array, open metal The outer boundary of the ring is circular, and the inner cavity is a U-shaped structure, as shown in FIG. 3(B). The adjustable range of its size parameters is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com