Temperature-evenness loop heat pipe device

A loop heat pipe and thermostat technology, applied in circuits, tubular components, heat transfer modification, etc., can solve problems such as unsatisfactory effects, achieve obvious heat transfer capacity and effect, improve flexibility and accuracy, and be flexible. The effect of improved performance and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

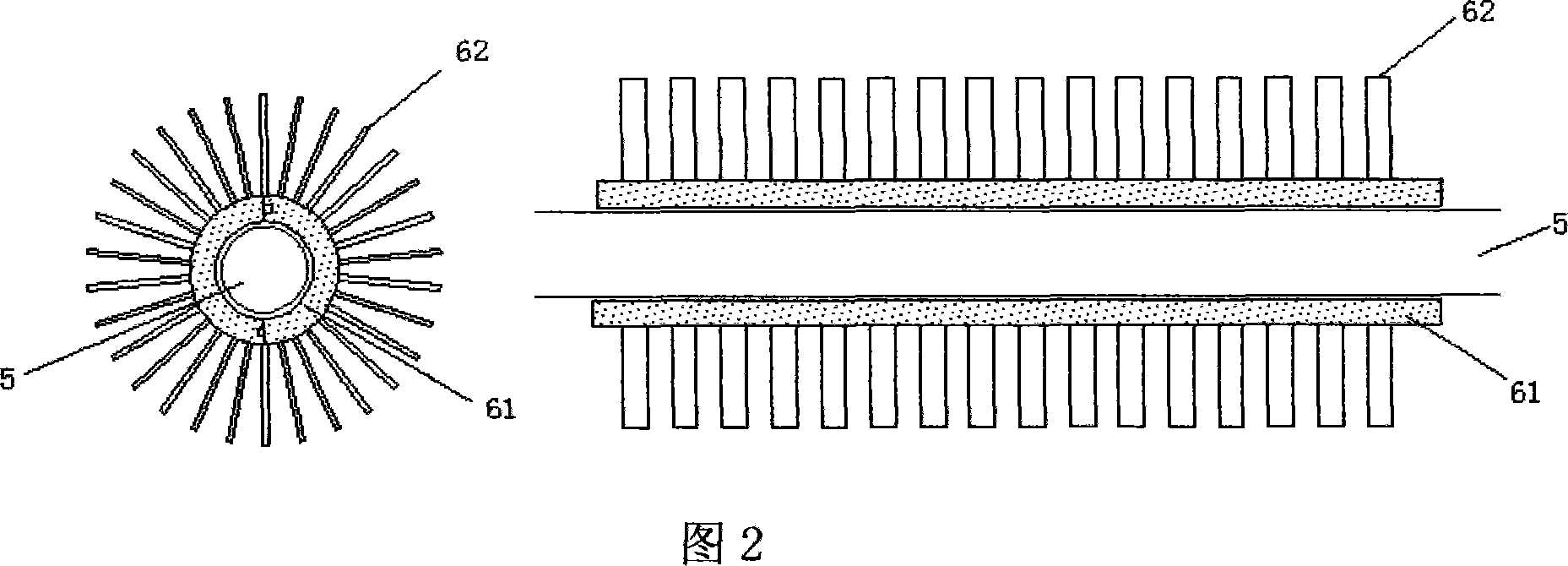

[0022] As shown in Figure 1, a heat pipe device for a uniform temperature circuit includes an evaporator 1, a compensator 2 and a thermostat 3, and the evaporator 1 and the compensator 2 are placed in the same container 7; the condensation end 11 of the evaporator 1 is connected to the The compensator 2 is connected, the evaporating end 12 of the evaporator 1 is connected with the condensing end 35 of the thermostat 3, the evaporator 1 is equipped with a liquid-absorbing core 4, and a steam groove is formed between the channel at the bottom of the liquid-absorbing core 4 and the evaporator 1 Road 41, the steam channel 41 communicates with the steam pipeline 5, the outer surface of the steam pipeline 5 is provided with a condenser 6, and the return pipe of the steam pipeline 5 communicates with the compensator 2; the inner surface of the equalizer 3 is covered with a metal mesh 31, and the metal mesh 31 is covered with a metal plate 32 with ventilation holes, and its upper and l...

Embodiment 2

[0025] Embodiment 2 Elastic and diversified cooling module system

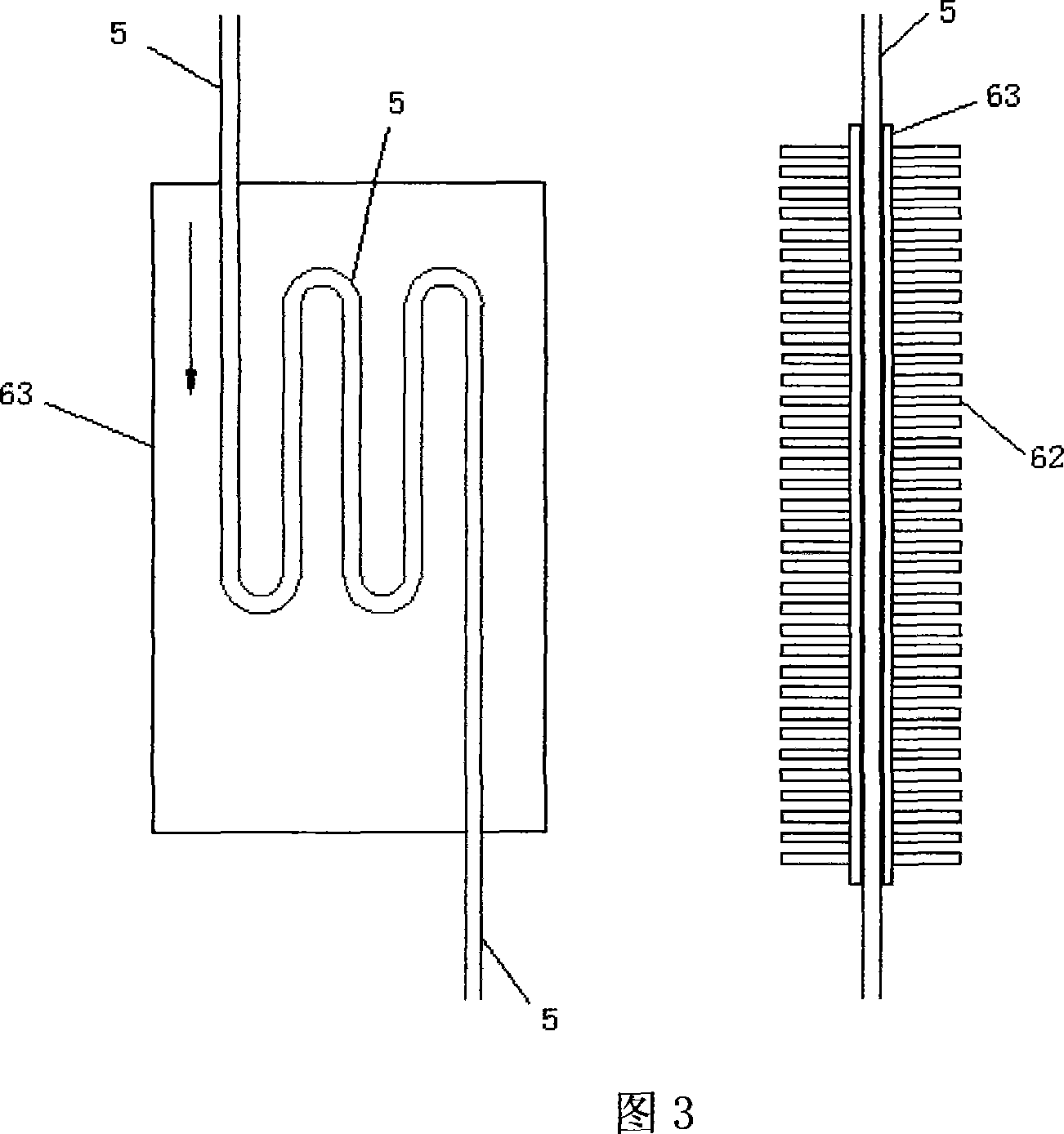

[0026] Figure 3 is a schematic diagram of the structure of a splint condenser. The splint condenser 6 is composed of a splint 63 and a large number of fins 62 . The splint 63 is a double-sided or single-sided splint.

[0027] Fig. 4 is a schematic diagram of the integrated structure of the condensing fin and the temperature control fin. In order to improve the flexibility and accuracy of the system's temperature control, it can meet the requirements of the maximum heat transfer capacity of the system. The condensing splint 63 can be extended to the entire temperature equalizing circuit heat pipe device, and the temperature control fin 8 and the condensing fin 62 are arranged on the other side of the condensing splint 63, so that the temperature control fin 8 and the condensing fin 62 are integrated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com