Technique method of treatment for modifying surface of ferrous material

A technology of iron and steel materials and processing technology, which is applied in the direction of metal material coating technology, coating, solid diffusion coating, etc., and can solve problems such as environmental pollution, slow cooling rate, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this embodiment, the piston component used in the automobile brake system is used as the test object, and the piston is made of 10# steel material.

[0016] The processing steps of piston steel surface are as follows:

[0017] (1) First, the surface of the piston steel is vacuum cleaned, and then placed in a furnace for pre-oxidation at a temperature of 400°C. Pre-oxidation can form a layer of Fe on the surface of the workpiece 3 o 4 , It is beneficial to the nitriding process, and it can also play a role in preheating to reduce the deformation of the workpiece.

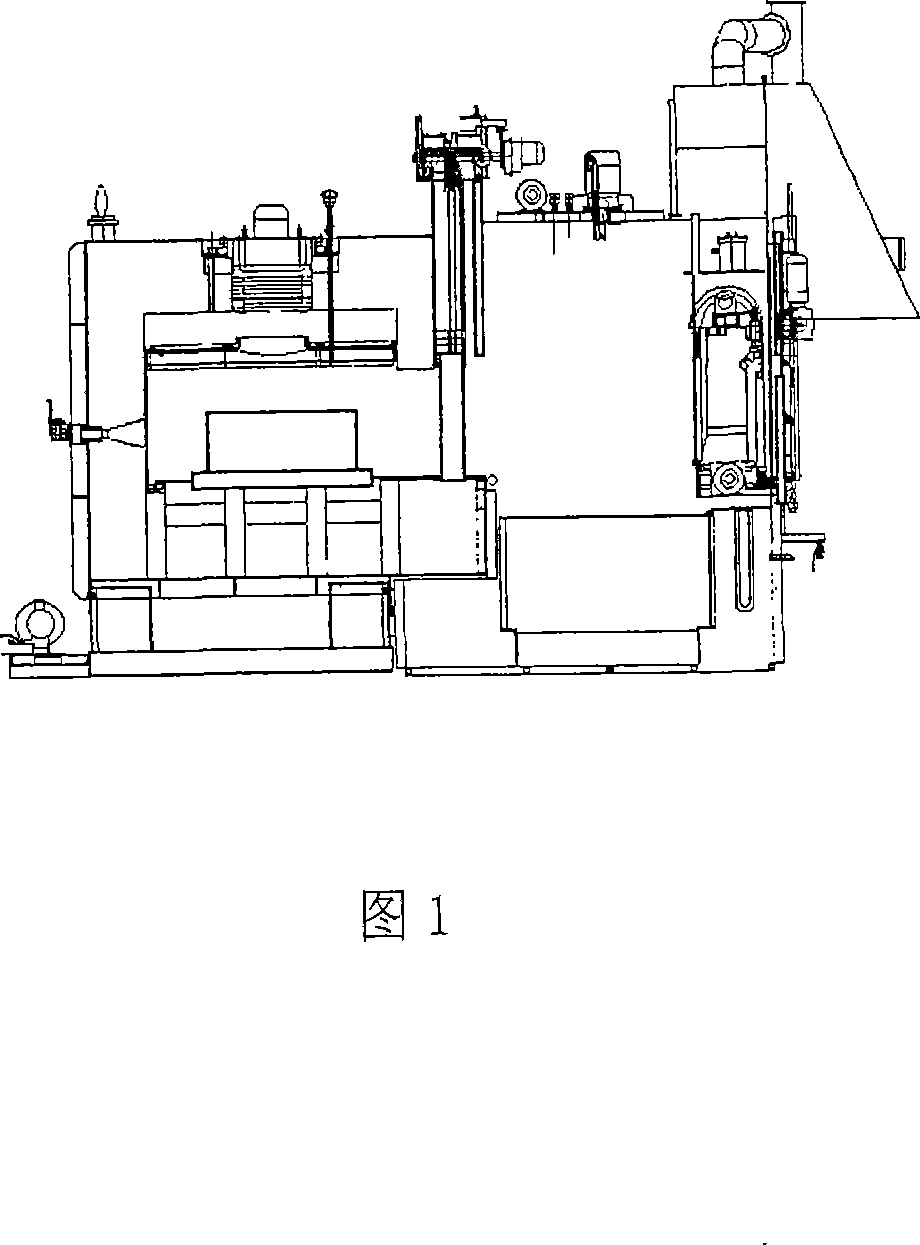

[0018] (2) Put the piston into the existing Aichelin box-type nitrocarburizing heat treatment furnace (see Figure 1), and input NH into the furnace 3 , N 2 and CO 2 The mixed gas; the volume flow ratio of the mixed gas is: NH 3 :N 2 :CO 2 =50:45:5; heating to a reaction temperature of 560° C., a reaction time of 4 hours, and oil cooling after the reaction.

[0019] (3) Polish the cooled piston part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com