Hybridization material of Nano fiber of titanium oxide / polyaniline, and preparation method

A technology of nanofibers and hybrid materials, applied in the field of nano-hybrid materials and their preparation, can solve the problems of high use cost, poor processability of conductive polymers, low mechanical strength, etc., and achieves low price, components and performance. The effect of easy control and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

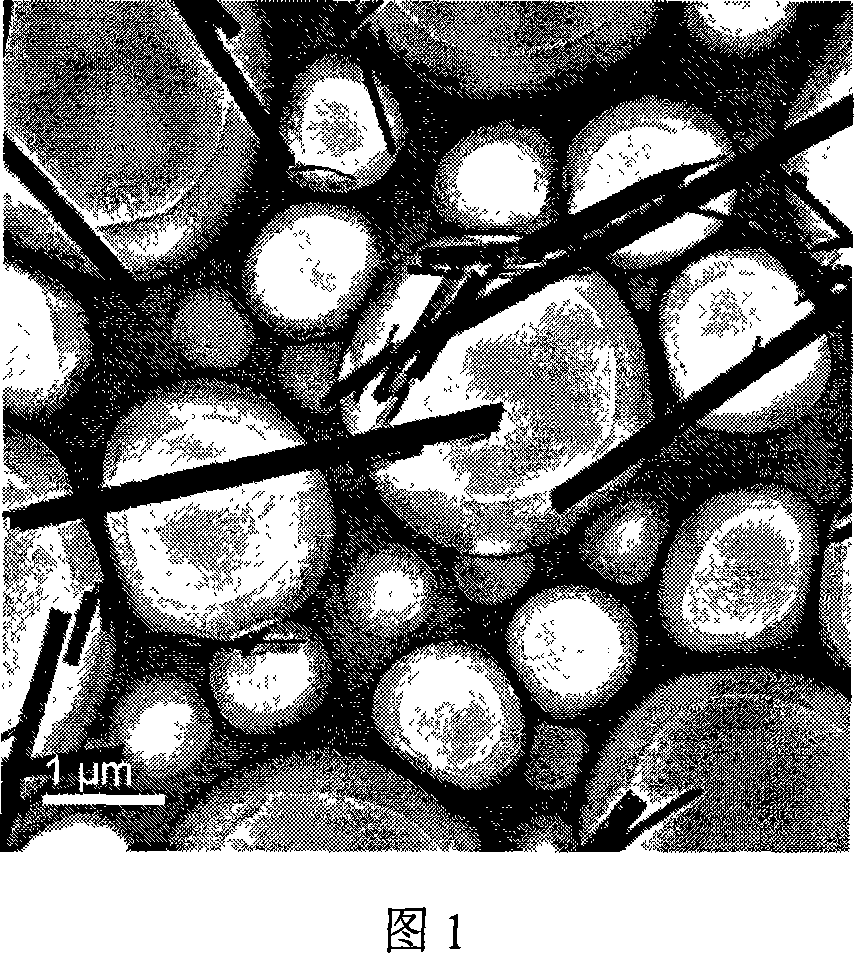

Image

Examples

Embodiment 2

[0024] Example 2 (polyaniline nanofibers)

[0025] 20mmol of aniline monomer and 0.50g of polyvinyl pyrrolidone (PVP) were added to 60ml of 1M hydrochloric acid aqueous solution and stirred, and stirred at room temperature for 24 hours to make the whole system dispersed uniformly; 5.0mmol of ammonium persulfate was added to 60ml of 1M hydrochloric acid solution and stirred well, Then under the condition of rapid stirring, the ammonium persulfate solution was quickly poured into the aniline solution, and the product was filtered after half an hour of polymerization, and repeatedly washed with deionized water until the filtrate was colorless, and the unreacted monomers, initiators, Surfactant, etc.; then transfer the filter cake into a vacuum drying oven, vacuum dry at 80°C for 4 hours, and grind the particles to obtain polyaniline nanofiber particles.

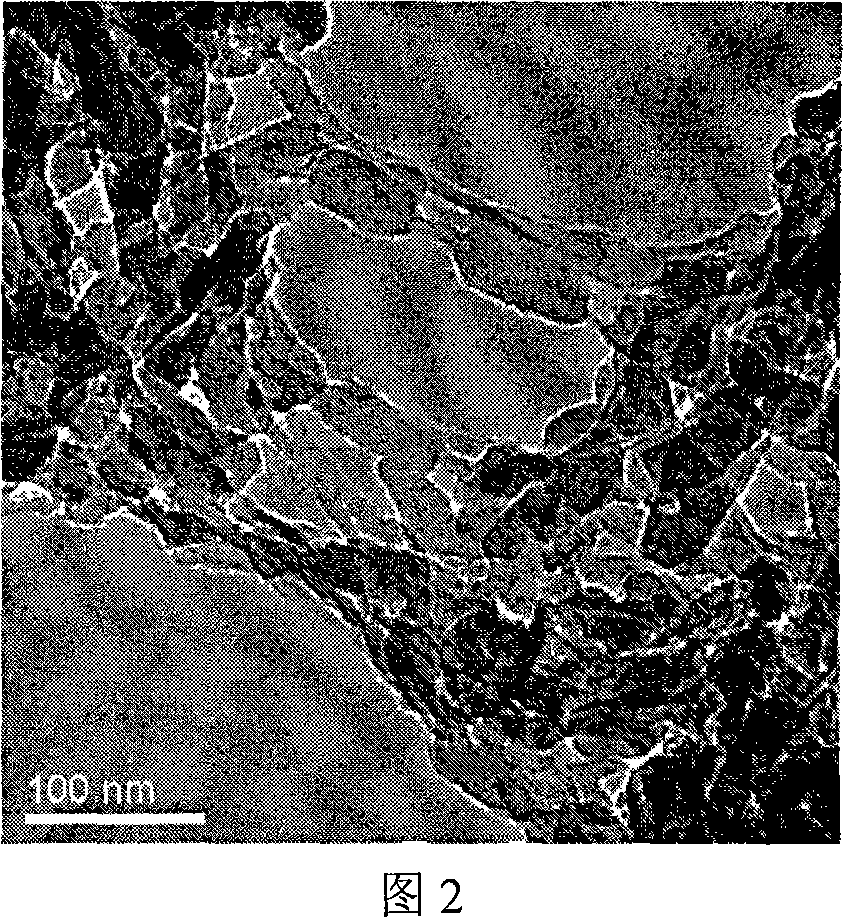

[0026] The lens photo of the polyaniline nanofiber particles is shown in Figure 2. The diameter of the nan...

Embodiment 3

[0027] Example 3 (titanium oxide / polyaniline nanofiber hybrid material)

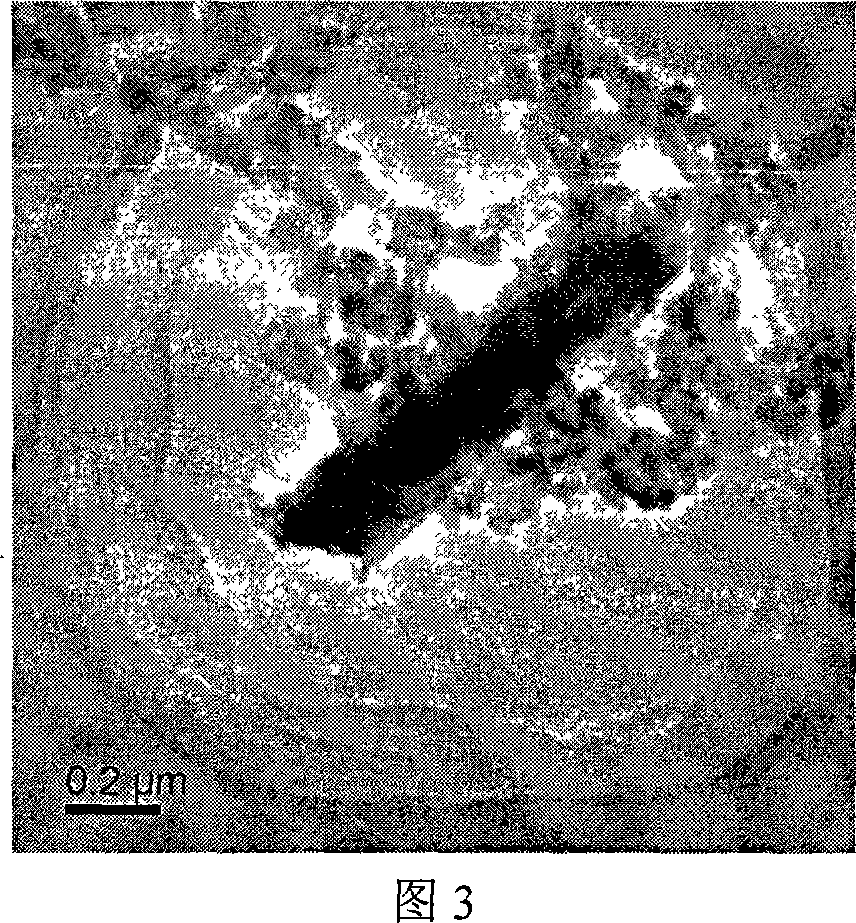

[0028] First, 0.5g of titanium oxide powder was added to 30ml of 10M potassium hydroxide solution, stirred at room temperature for half an hour, all transferred to a hydrothermal kettle with a polytetrafluoroethylene lining, heated in a closed state, and maintained at 180 ° C for reaction For 48 hours, the product was repeatedly washed and filtered with 0.1M hydrochloric acid solution and deionized water until the pH value of the filtrate was less than 7. The filter cake was transferred to a vacuum drying oven, and vacuum-dried at 80 ° C for 4 hours to obtain titanium oxide nanorods. Then add the titanium oxide nanorods of 0.2g in the 1M hydrochloric acid aqueous solution of 60ml and stir, then add 20mmol aniline monomer, and continue to stir at room temperature for 24 hours to make the whole system uniformly dispersed; 5mmol ammonium persulfate is added to the 1M hydrochloric acid solu...

Embodiment 4

[0029] Embodiment 4 (titanium oxide / polyaniline nanofiber hybrid material):

[0030] First, 0.5g of titanium oxide powder was added to 30ml of 10M potassium hydroxide solution, stirred at room temperature for half an hour, all transferred to a hydrothermal kettle with a polytetrafluoroethylene lining, heated in a closed state, and maintained at 180 ° C for reaction For 48 hours, the product was repeatedly washed and filtered with 0.1M hydrochloric acid solution and deionized water until the pH value of the filtrate was less than 7. The filter cake was transferred to a vacuum drying oven, and vacuum-dried at 80 ° C for 4 hours to obtain titanium oxide nanorods. ; Add the titanium oxide nanorods of 0.2g to the 1M aqueous hydrochloric acid solution of 60ml and stir evenly, then add 20mmol of aniline monomer and 0.50g of polyvinyl pyrrolidone (PVP), and continue to stir at room temperature for 24 hours to make the whole system uniformly dispersed; 5mmol of ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com