Preparation method of melamine resin double coated Deca-BDE

A technology of decabromodiphenyl ether and formaldehyde resin, which is applied in the direction of fire-resistant coatings, etc., can solve the problems of hindering the application of brominated flame retardants and the inability to achieve flame-retardant effects, and achieve good compactness, fast curing speed, and coating full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

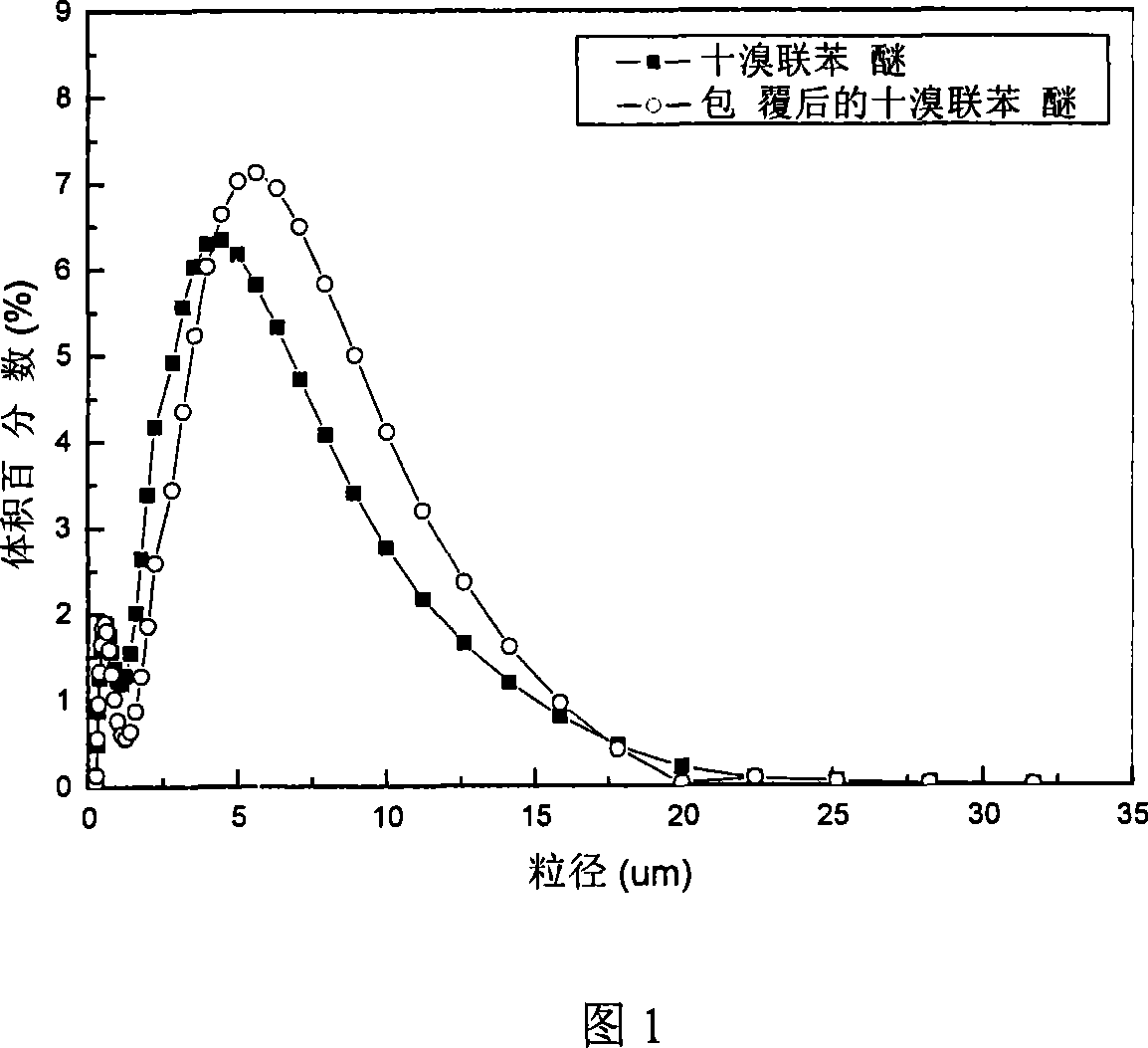

Image

Examples

Embodiment 1

[0024] (1) Add 20kg of decabromodiphenyl ether, 0.5kg of styrene maleic anhydride resin, 0.5kg of Tween 20, and 100kg of water into a reaction kettle with a stirrer and a thermometer, and heat up to 80°C at a stirring speed of 3000rpm. the dispersion;

[0025] (2) 15kg of melamine, 50kg of 37% formaldehyde solution, and 80kg of water are added together in a reaction kettle with a stirrer and a thermometer to stir and mix. When the temperature rises to 80°C, adjust its pH value to 8 with sodium carbonate, and then stir for 10 Obtain transparent melamine formaldehyde resin prepolymer in minutes;

[0026] (3) The melamine-formaldehyde resin prepolymer obtained in the step (2) is divided into two parts on average, one part is added to the dispersion liquid obtained in the step (1) and mixed, and then the pH value is adjusted to 5 with acetic acid. Keep the temperature at 80°C, stir and react at a stirring speed of 3000rpm for 2 hours, then add another part of melamine formaldehyd...

Embodiment 2

[0030] (1) Add 100kg of decabromodiphenyl ether, 10kg of polyvinyl alcohol, 10kg of Tween 60, and 100kg of water into a reaction kettle with a stirrer and a thermometer, and heat up to 70°C at a stirring speed of 1000rpm to disperse them;

[0031] (2) Add 20kg of melamine, 60kg of 37% formaldehyde solution, and 150kg of water together into a reaction kettle with a stirrer and a thermometer and stir and mix them. When the temperature rises to 70°C, adjust its pH value to 9 with sodium hydroxide, and then stir the reaction Obtain transparent melamine formaldehyde resin prepolymer in 30 minutes;

[0032] (3) The melamine-formaldehyde resin prepolymer obtained in step (2) is divided into two parts on average, one part is added to the dispersion liquid obtained in step (1) and mixed, then the pH value is adjusted to 3 with hydrochloric acid. Keep the temperature at 70°C and stir at a stirring speed of 1000rpm for 1 hour, then add another part of melamine-formaldehyde prepolymer, an...

Embodiment 3

[0036] (1) Add 40 kg of decabromodiphenyl ether, 80 5 kg of Tween, 40 7 kg of Tween, and 450 kg of water into a reaction kettle with a stirrer and a thermometer, and heat up to 80 ° C at a stirring speed of 2500 rpm to disperse it;

[0037] (2) Add 5 kg of melamine, 10 kg of 37% formaldehyde solution, and 50 kg of water together into a reaction kettle with a stirrer and a thermometer and stir and mix them. When the temperature rises to 80°C, adjust the pH value to 7 with sodium bicarbonate, and then stir the reaction Obtain transparent melamine formaldehyde resin prepolymer in 10 minutes;

[0038] (3) The melamine-formaldehyde resin prepolymer obtained in step (2) is divided into two parts on average, one of them is added to the dispersion obtained in step (1) and mixed, then the pH value is adjusted to 4 with acetic acid. Keep the temperature at 80°C, stir and react at a stirring speed of 2500rpm for 3 hours, then add another part of melamine formaldehyde prepolymer, and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial thermal decomposition temperature | aaaaa | aaaaa |

| Initial thermal decomposition temperature | aaaaa | aaaaa |

| Initial thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com