Preparation method of spherical charcoal-aero gel

A carbon aerogel and spherical technology, applied in the field of preparation of spherical carbon aerogel, can solve the problems of high price, poor sphericity, limited commercial application prospects, etc., and achieve the effect of shortening the synthesis process and broadening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Synthetic method of the present invention comprises the steps:

[0023] (1) Mix the various components constituting the organogel to form a sol monomer, and perform pre-polymerization at an appropriate temperature for 0-10 hours.

[0024] (2) Prepare an organic solvent containing a certain concentration of surfactant. Add 10 to 50 times the volume of the sol volume of the organic solvent into the reactor, raise the temperature to 60°C to 85°C, stir at a speed of 50 to 400 rpm, add an appropriate volume of sol after prepolymerization, and stir at a constant temperature and speed 3~24h. The spherical hydrogel can be obtained by further aging at room temperature to 85°C.

[0025] (3) replacing the water in the hydrogel with an organic solvent to obtain an organogel.

[0026] (4) Put the organogel in an autoclave and fill it with petroleum ether, and dry it under supercritical conditions at 240-300°C and 4.5-12Mpa for 1-3 hours, or use carbon dioxide as the drying medium...

Embodiment 1

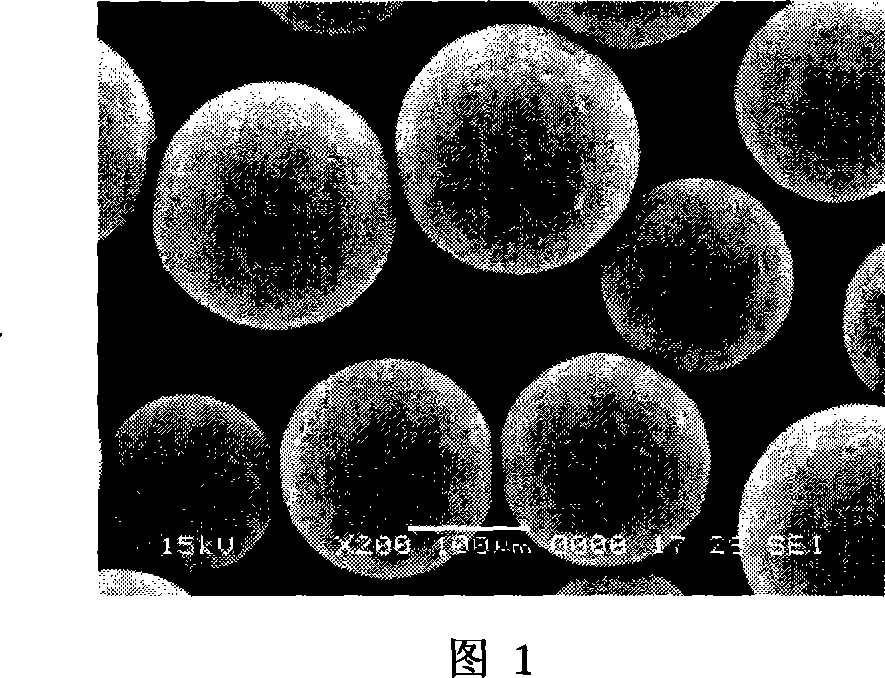

[0034] Mix phenol, melamine and formaldehyde in a molar ratio of 1:0.4:3, add catalyst NaOH with 1% of the total mass of the reactant, then add a certain amount of deionized water to make the total concentration of the reactant 18g / 100ml, and react at 85°C for 5 Hours. Then 20 ml of the reaction solution was poured into 500 ml of cyclohexane containing 0.1 ml of Span80, and stirred at 67° C. at a stirring speed of 400 rpm for 4 h. Continue heating for 72 hours after stopping stirring, and centrifuge to obtain hydrogel balls. Acetone was used to replace the water in the gel to obtain a spherical ketone gel. Put the ketone gel in an autoclave and fill it with petroleum ether, raise the temperature to 250°C, and keep the pressure in the autoclave at 8Mpa, supercritically dry for 3 hours, then slowly release the pressure at a constant temperature and cool naturally to obtain a spherical organic aerogel; Put the obtained airgel into a high-temperature cracking furnace, raise the ...

Embodiment 2

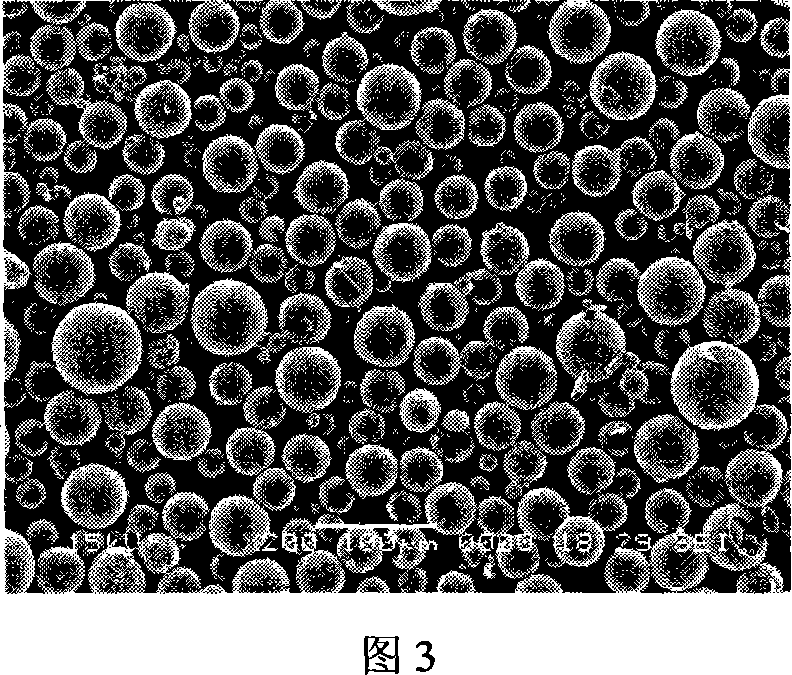

[0036] Mix phenol, melamine and formaldehyde in a molar ratio of 1:0.2:3, add catalyst NaOH with 1% of the total mass of the reactant, then add a certain amount of deionized water to make the total concentration of the reactant 18g / 100ml, and react at 85°C for 5 Hours. Then 20 ml of the reaction solution was poured into 500 ml of cyclohexane containing 0.1 ml of Span80, and stirred at 67° C. at a stirring speed of 400 rpm for 4 h. Continue heating for 72 hours after stopping stirring, and centrifuge to obtain hydrogel balls. Acetone was used to replace the water in the gel to obtain a spherical ketone gel. Put the ketone gel in an autoclave and fill it with petroleum ether, raise the temperature to 250°C, and keep the pressure in the autoclave at 8Mpa, supercritically dry for 3 hours, then slowly release the pressure at a constant temperature and cool naturally to obtain a spherical organic aerogel; Put the obtained airgel into a high-temperature cracking furnace, raise the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com