Coking scaling inhibitor and its preparation and application

An inhibitor and coke scale technology, which is applied in the treatment equipment corrosion/fouling inhibition, petroleum industry, cracking and other directions, can solve the problems of general effect and reduce generation, and achieve the effect of enhanced coke inhibition efficiency and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

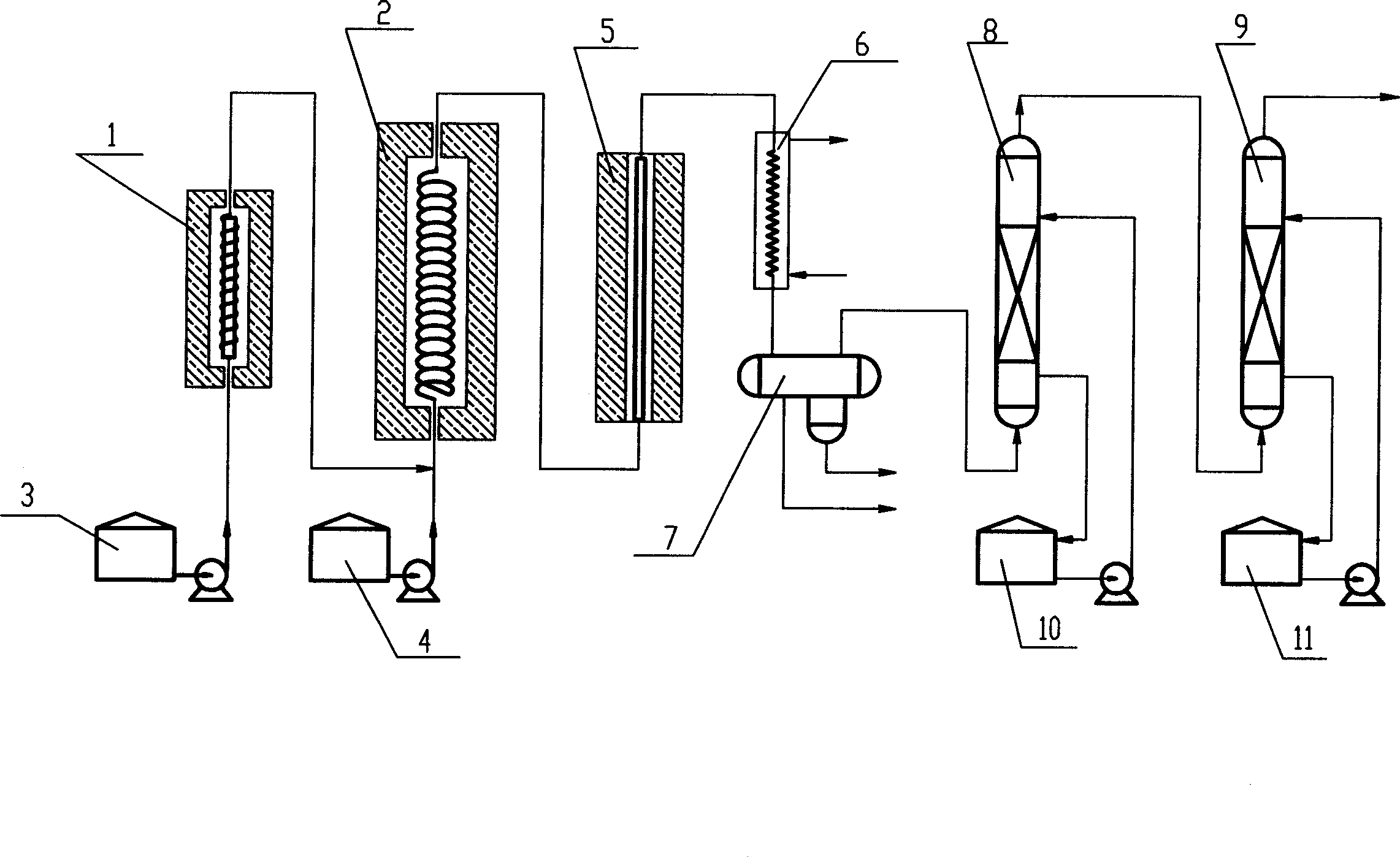

Image

Examples

Embodiment 1

[0036] The structure and preparation method of the new compound A.

[0037] 1. The structure of the new compound A

[0038]

[0039] 2. Preparation method

[0040] 1) First put 260 grams (2mol) of isooctyl alcohol and 100 grams of xylene into a 500ml four-necked flask equipped with a stirrer, a thermometer and a condenser. Start the stirring device and simultaneously turn on the condensed water in the condenser, then slowly add 110 grams (0.5 mol) of phosphorus pentasulfide, and when the temperature rises to 120° C., keep the temperature at a constant temperature of 0.1 MPa for 5 hours.

[0041] 2) the first step reaction product is cooled to 70 ℃, it and 100 gram xylenes are added in the flask that agitator, thermometer, condenser, water separator are housed, then slowly 85 gram (0.33mol) dioxide trioxide Antimony was added, and the reactants were kept at 70°C and 0.1Mpa for 7 hours, until no water came out in the water separator, and 1 mol of the compound of formula (3) w...

Embodiment 2

[0043] The structure and preparation method of the new compound B.

[0044] 1. The structure of the new compound B

[0045]

[0046] 2. Preparation method

[0047] 1) Put 150 grams (2mol) of n-butanol and 70 grams of xylene into a 500ml four-necked flask equipped with a stirrer, a thermometer and a condenser. Start the stirring device and turn on the condensed water of the condenser at the same time, then add 110 (0.5mol) gram of phosphorus pentasulfide, when the temperature rises to 160°C, keep the temperature at a pressure of 0.1Mpa for 4 hours.

[0048] 2) the first step reaction product is cooled to 75 ℃, and it and 70 grams of xylene are added in the flask that agitator, thermometer, condenser, water trap are equipped with, then slowly 37 grams (0.25mol) tin dioxide Adding, keeping the reactant at 75° C., reacting for 4 hours under the condition of 0.1 Mpa, until no water comes out in the water separator, and 1 mol of the compound of formula (4) is generated.

Embodiment 3

[0050] The structure and preparation method of the new compound C.

[0051] 1. The structure of the new compound C

[0052]

[0053] 2. Preparation method

[0054] 1) Put 186 grams (1mol) of dodecanol and 90 grams of xylene into a 500ml four-necked flask equipped with a stirrer, a thermometer and a condenser. Start the stirring device and open the condensed water of the condenser at the same time, then add 27 grams (0.25mol) of phosphorus pentasulfide, and when the temperature is raised to 150° C., keep the temperature at a pressure of 0.1 MPa for 5 hours.

[0055] 2) the first step reaction product is cooled to 80 ℃, it and 90 gram xylenes are added in the flask that agitator, thermometer, condenser, water trap are equipped with, then slowly 46 gram (0.16mol) dioxide trioxide Lanthanum was added, and the reactants were kept at 80° C. and 0.1 Mpa for 6 hours until no water came out in the separator, and 0.5 mol of the compound of formula (5) was generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com