Crosslinking-type rubber-base damping material and preparing method thereof

A damping material and rubber-based technology, applied in the field of cross-linked rubber-based damping materials and their preparation, can solve the problems of unsatisfactory sound wave damping effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

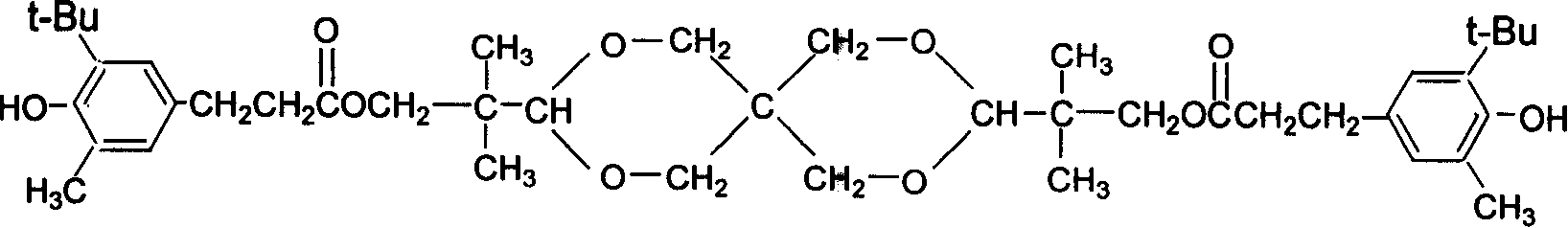

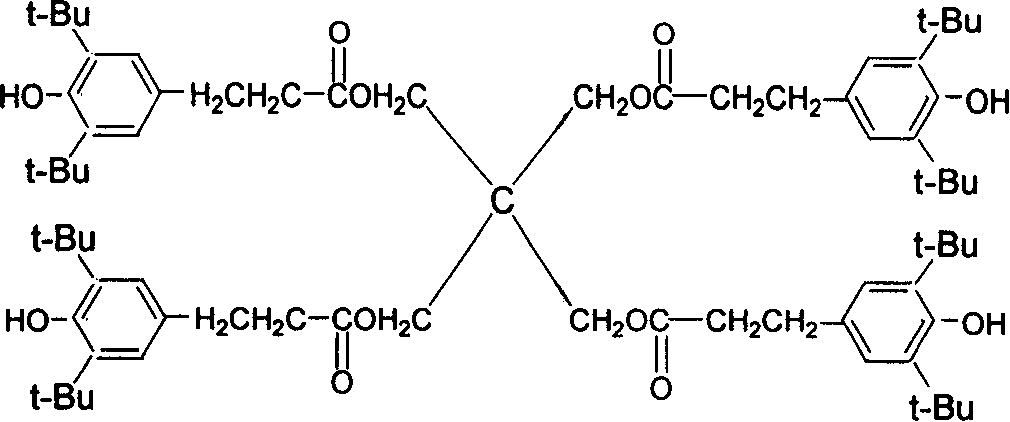

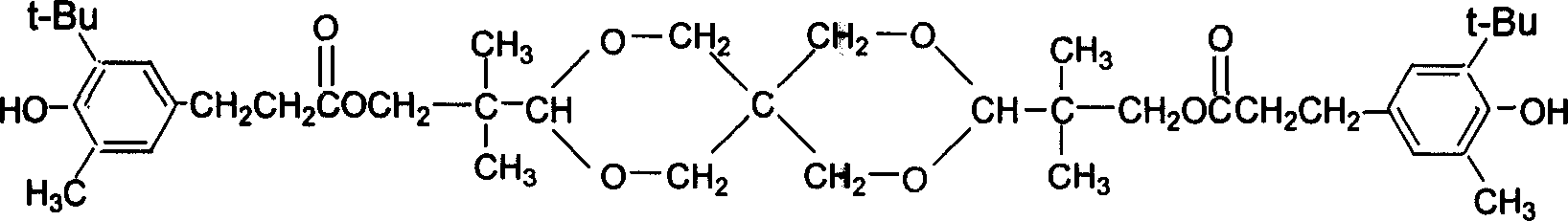

Method used

Image

Examples

Embodiment 1 to 9

[0028] The rubber-based damping materials prepared in Examples 1 to 9 all use 100 parts by mass of nitrile rubber as the base rubber, and add the phenolic organic small molecules shown in Table 1 as functional additives, and the added parts by mass are also given in Table 1. out. The specific preparation method and steps are: (1) masticating nitrile rubber on an open mill for 3-5 minutes at room temperature, then adding phenolic organic small molecules, kneading for 5-8 minutes with a knife, thinning, and making triangular bags , to make it kneaded evenly, and the next sheet; (2) the obtained mixture was kneaded at a high temperature for 5-8 minutes, and the kneading temperature was as listed in Table 1, so that the additives were fully melted, blanked, and cooled at room temperature; (3) room temperature Next, add various vulcanization system compounding agents to the compound obtained on the open mill, knead for 5-8 minutes, thinly pass, make a triangle bag, make it mix even...

Embodiment 10 to 18

[0044] For each of the rubber-based damping materials prepared in Examples 10 to 18, the matrix rubber is nitrile rubber / polyvinyl chloride co-precipitation glue (70 / 30, mass ratio, polyvinyl chloride resin as a compatibilizer), and then add Table 3 The phenolic organic small molecules shown are used as functional additives, and the addition amounts are also given in Table 3. The specific preparation method and steps are: (1) masticate the nitrile rubber / polyvinyl chloride co-precipitated rubber on an open mill for 3-5 minutes at room temperature, then add phenolic small molecules, and knead for 5-8 minutes, Thin pass, make a triangular bag, make it knead evenly, and release the tablet; (2) knead the obtained mixture at high temperature for 5-8 minutes, the temperature is listed in Table 3, make the additive fully melt, cut the material, and cool at room temperature; ( 3) At room temperature, add various vulcanization system compounding agents to the obtained compound on an op...

Embodiment 19

[0058] For the rubber-based damping material prepared in Example 19, the matrix is styrene-butadiene rubber, and the compatibilizer is brominated phenolic resin (the mass ratios of styrene-butadiene rubber and brominated phenolic resin are respectively 80 / 20, and the brominated phenolic resin is used simultaneously as cross-linking agent), adding the phenolic organic small molecules shown in Table 5, they are used as functional additives, and the addition amount is also given in Table 5. The specific preparation method and steps are: (1) masticating styrene-butadiene rubber on an open mill for 3-5 minutes at room temperature, then adding small phenolic molecules, kneading for 5-8 minutes with a knife, thinning, making triangular bags, Make it kneaded evenly, and lower the tablet; (2) knead the obtained mixture at high temperature for 5-8 minutes, and the temperature is listed in Table 5, so that the additives are fully melted, blanked, and cooled at room temperature; (3) at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com