Ship perfusion sealing damping vibration attenuation material and preparation method thereof

A damping material and damping technology, which is applied in the field of damping materials, can solve the problems of wide damping temperature range, high loss factor, non-existence, etc., and achieve the effects of improving flame retardancy, improving mechanical properties, and enhancing damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A ship perfusion seal damping vibration damping material is characterized in that: it includes A component and B component, wherein, A component includes the following raw materials in parts by weight: 100 parts of oligomer polyol, 25 parts of toluene di Isocyanate; component B includes the following raw materials in parts by weight: 100 parts of oligomer polyol, 40 parts of chain-extending cross-linking agent, and 40 parts of damping filler.

[0024] Wherein, the oligomer polyol includes two or more of hydroxyl-terminated polybutadiene, polytetrahydrofuran ether diol, polycaprolactone diol, and polycarbonate diol. Specifically, the oligomer in this embodiment Polyols include hydroxyl-terminated polybutadiene and polycaprolactone diols;

[0025] Among them: the mass ratio of hydroxyl-terminated polybutadiene to toluene diisocyanate in component A is 4:1; the mass ratio of polycaprolactone diol to chain-extending crosslinking agent and damping filler in component B is 10...

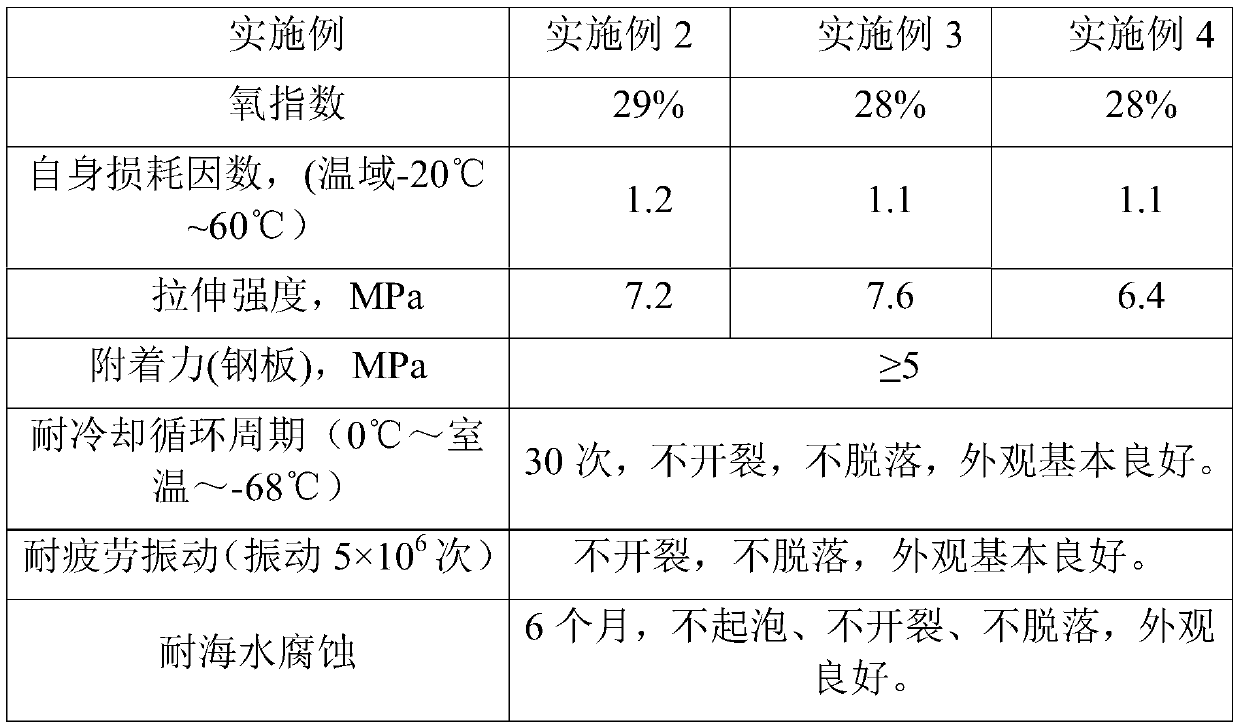

Embodiment 2

[0031] A ship perfusion sealing damping vibration damping material is characterized in that: it includes A component and B component, wherein, A component includes the following raw materials by weight: 100 parts of oligomer polyol, 62.5 parts of diphenyl Methane diisocyanate; B component includes the following raw materials in parts by weight: 100 parts of oligomer polyol, 50 parts of chain-extending cross-linking agent, 40 parts of damping filler.

[0032] Wherein, the oligomer polyol includes two or more of hydroxyl-terminated polybutadiene, polytetrahydrofuran ether diol, polycaprolactone diol, and polycarbonate diol. Specifically, the oligomer in this embodiment Polyols include hydroxyl-terminated polybutadiene and polytetrahydrofuran ether glycol;

[0033] Among them: the mass ratio of hydroxyl-terminated polybutadiene to diphenylmethane diisocyanate in component A is 100:62.5; the mass ratio of polycaprolactone diol to chain-extending crosslinking agent and damping fill...

Embodiment 3

[0039] A ship perfusion sealing damping vibration damping material: including A component and B component, wherein, A component includes the following raw materials in parts by weight: 100 parts of polycaprolactone diol, its relative molecular mass is 2000±50, The hydroxyl value is 56±3mgKOH / g, 25 parts of TDI-80 / 20, the isocyanate content in component A is 6.2%±0.5%;

[0040] Component B includes the following raw materials in parts by weight: 60 parts of polytetrahydrofuran ether glycol with a relative molecular weight of 1000±50 and a hydroxyl value of 107-118 mgKOH / g;

[0041] 40 parts of polycarbonate diol, its relative molecular mass is 2000±50, the hydroxyl value is 56±5mgKOH / g, and the acid value is ≤0.1mgKOH / g;

[0042]26 parts of bis-sec-butylaminodiphenylmethane, 6 parts of 1,4-butanediol, 4 parts of γ-aminopropyltriethoxysilane, 35 parts of phosphine composite flame retardant FR-8107, 15 parts of dimethyl methylphosphonate, 22 parts of mica powder, 18 parts of N,N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com