A two-component epoxy-based flame-retardant low-toxic caulking agent and preparation method thereof

An epoxy-based, two-component technology, applied in the field of coatings, can solve the problem that it is not suitable for ships, does not meet the requirements of marine caulking agents, does not have low toxicity, flame retardant, seawater corrosion resistance, self-leveling, smoke suppression, etc. problem, to achieve good self-leveling characteristics, less addition, and the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

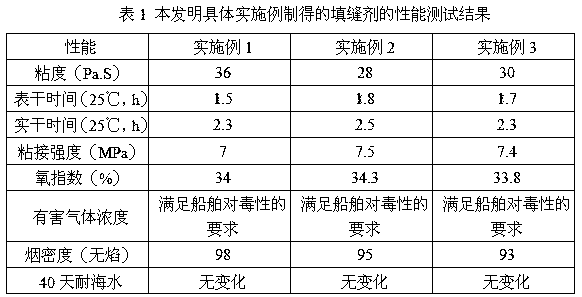

Examples

preparation example Construction

[0025] The preparation method of the two-component epoxy-based flame-retardant low-toxicity caulking agent of the present invention, the detailed steps are as follows:

[0026] (1) According to the ratio of the raw materials of the aforementioned caulking agent, weigh each raw material and set aside;

[0027] (2) Preparation of resin component A: Mix hydroxide compound, acid zinc compound, high wear-resistant carbon black and precipitated silica in a powder disperser, and the stirring blade rotates at 100-150r / min, and disperses Treat for 15-20 minutes to form a powder mixture; stir and mix the phosphating epoxy resin and silicone coupling agent in a double planetary mixer, the stirring speed is 40-60r / min, and the mixing time is 40-60min; the powder Put the mixture into the mixer, soak it for 10-12 hours and then stir it. The speed of the stirring blade is 100-120r / min, and the mixing time is 60-80min. Grind repeatedly on the grinder until the fineness is less than 50 μm, an...

Embodiment 1

[0031] Preparation of resin component A: In parts by weight, weigh 40 parts of magnesium hydroxide, 60 parts of zinc borate, 2 parts of high wear-resistant carbon black, and 10 parts of precipitated white carbon black, and put them into a powder disperser for mixing , stirring paddle speed 150r / min, dispersion treatment 20min, forming a powder mixture; stirring and mixing 100 parts of phosphating epoxy resin and 5 parts of anilinomethyltrimethoxysilane in a double planetary mixer, stirring speed 60r / min, mixing time 60min; put the powder mixture into the mixer, soak for 12h and then stir, the speed of the stirring paddle is 120r / min, and the mixing time is 80min; Grind to a fineness of 46 μm, and pack into barrels to obtain resin component A.

[0032] Preparation of curing agent component B: in parts by weight, weigh 40 parts of phenalkamine T31 and 10 parts of DMP-30 respectively, stir and mix in a double planetary mixer, the speed of the stirring blade is 60r / min, the mixing...

Embodiment 2

[0035] Preparation of resin component A: In parts by weight, weigh 60 parts of aluminum hydroxide, 40 parts of zinc stannate, 1 part of high wear-resistant carbon black, and 15 parts of precipitated white carbon black, and put them into a powder disperser for Mixing, stirring paddle speed 100r / min, dispersing treatment for 15min, forming a powder mixture; stirring and mixing 100 parts of phosphating epoxy resin and 3 parts of γ-aminopropyltriethoxysilane in a double planetary mixer, The speed of the stirring blade is 40r / min, and the mixing time is 50min; put the powder mixture into the mixer, soak for 10h and then stir, the speed of the stirring blade is 100r / min, and the mixing time is 60min; after stirring evenly, add the stirring material to the three-roll grinding Grind in the machine until the fineness is 48 μm, and put into barrels to obtain resin component A.

[0036]Preparation of curing agent component B: in parts by weight, weigh 50 parts of polyamide 651 and 8 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com