Damping steel rail

A rail and damping technology, which is applied in the field of damping rails, can solve the problems of loss of vibration and noise reduction effects, reduction of bonding strength of damping structures, and large temperature difference changes, etc., to achieve good shock absorption, broaden the frequency range, medium and low frequency vibration and noise The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

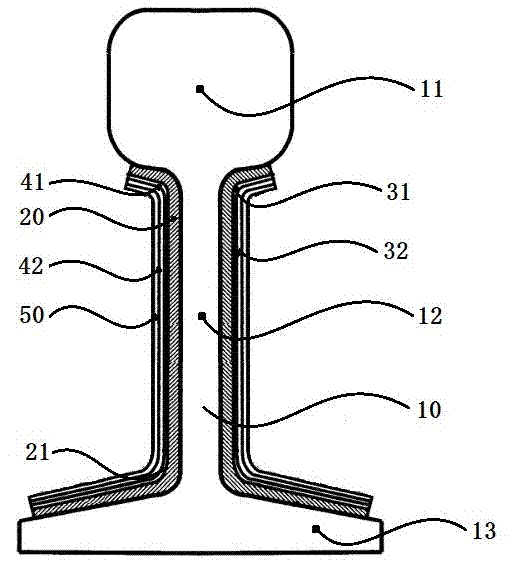

[0015] as attached figure 1 As shown, the damping rail described in this embodiment includes a rail body 10, the rail body 10 has a waist rail 12, a top rail 11 located at the upper end of the waist rail 12, and a rail seat 13 located at the lower end of the waist rail 12 The surface of the waist rail 12 has a layered structure, and the layered structure extends along the waist rail 12 to the top rail 11 and the rail seat 13 and the layered structure extends from the inside along the surface of the waist rail There are elastic energy dissipation layer 20 , magnetic adsorption layer 21 , first damping layer 31 , first constrained layer 41 , second damping layer 32 , second constrained layer 42 and protective layer 50 outside. The elastic energy-dissipating layer described in this embodiment can effectively absorb the energy of the low-frequency vibration of the rail; and the first damping layer and the second damping layer can further absorb the energy of the middle and high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com