An elastic metamaterial wheel structure with medium and low frequency vibration damping properties

A medium and low frequency, metamaterial technology, applied to springs made of plastic materials, low internal friction springs, springs, etc., can solve the problems that processing and manufacturing cannot be fully realized, and it is difficult to meet industrial requirements in strength and stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

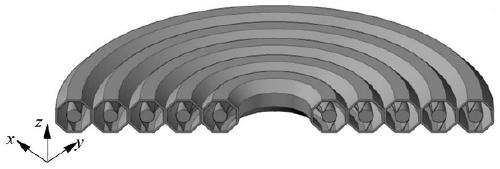

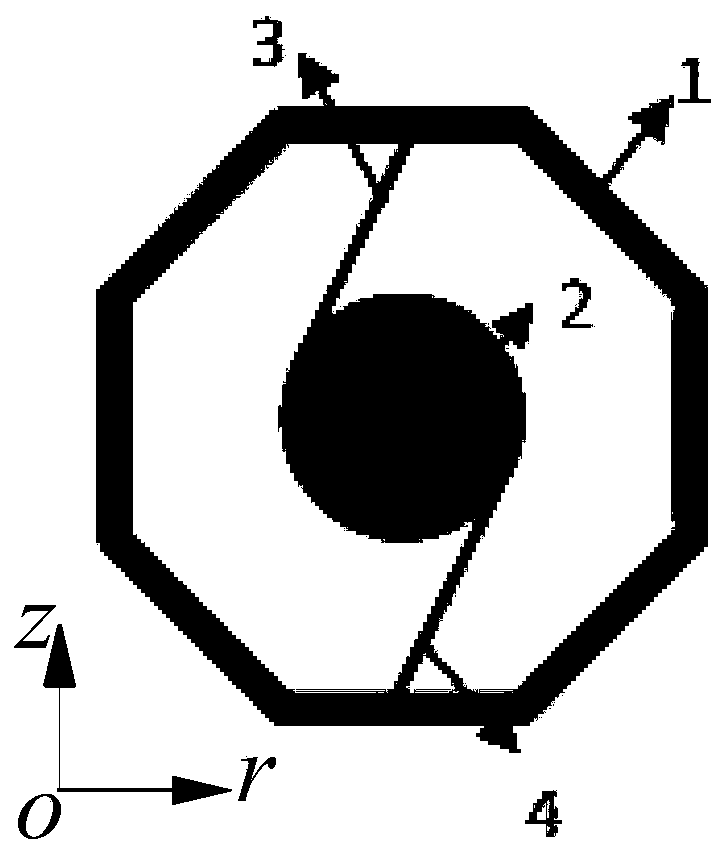

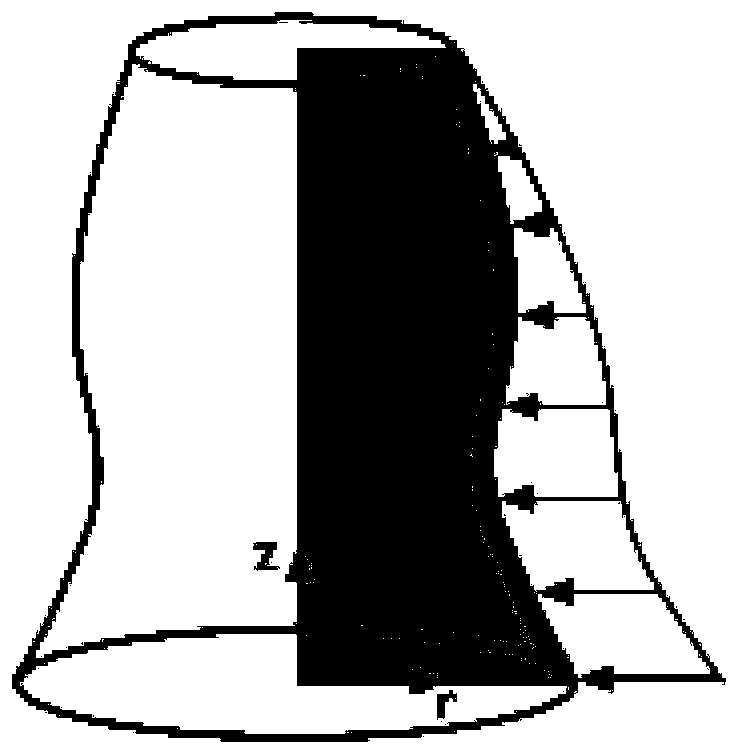

[0020] Such as figure 1 , figure 2 and image 3 As shown, an implementation method of the elastic metamaterial wheel structure of the present invention, the hollow ring structure is arranged in five periodic structures along the radial direction. The longitudinal section of the ring structure 1 is a regular octagon, and the interior is a middle ring cylinder 2, a ring connection block 1 3 and a ring connection block 2 4, and the ring connection block 1 3 and the ring connection block 2 4 are center-symmetrically distributed. The distance between the outermost layers of the annular structure 1 is 20mm, the wall thickness of the shell is 1mm, the section radius of the middle annular cylinder 2 is 4mm, and the thickness of the connecting block is 0.5mm. Use epoxy resin as the overall material of structure among the present invention, concrete m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com