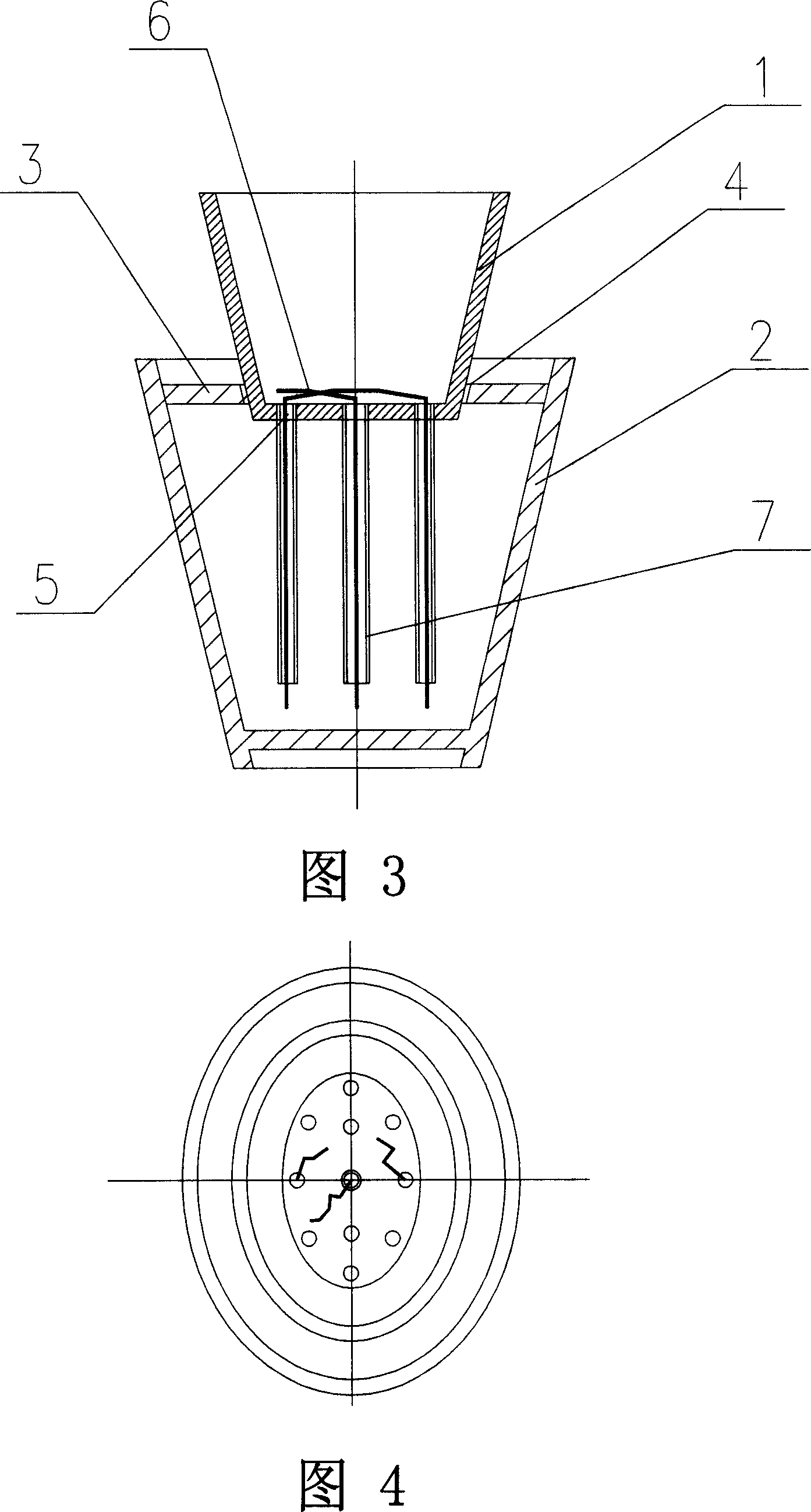

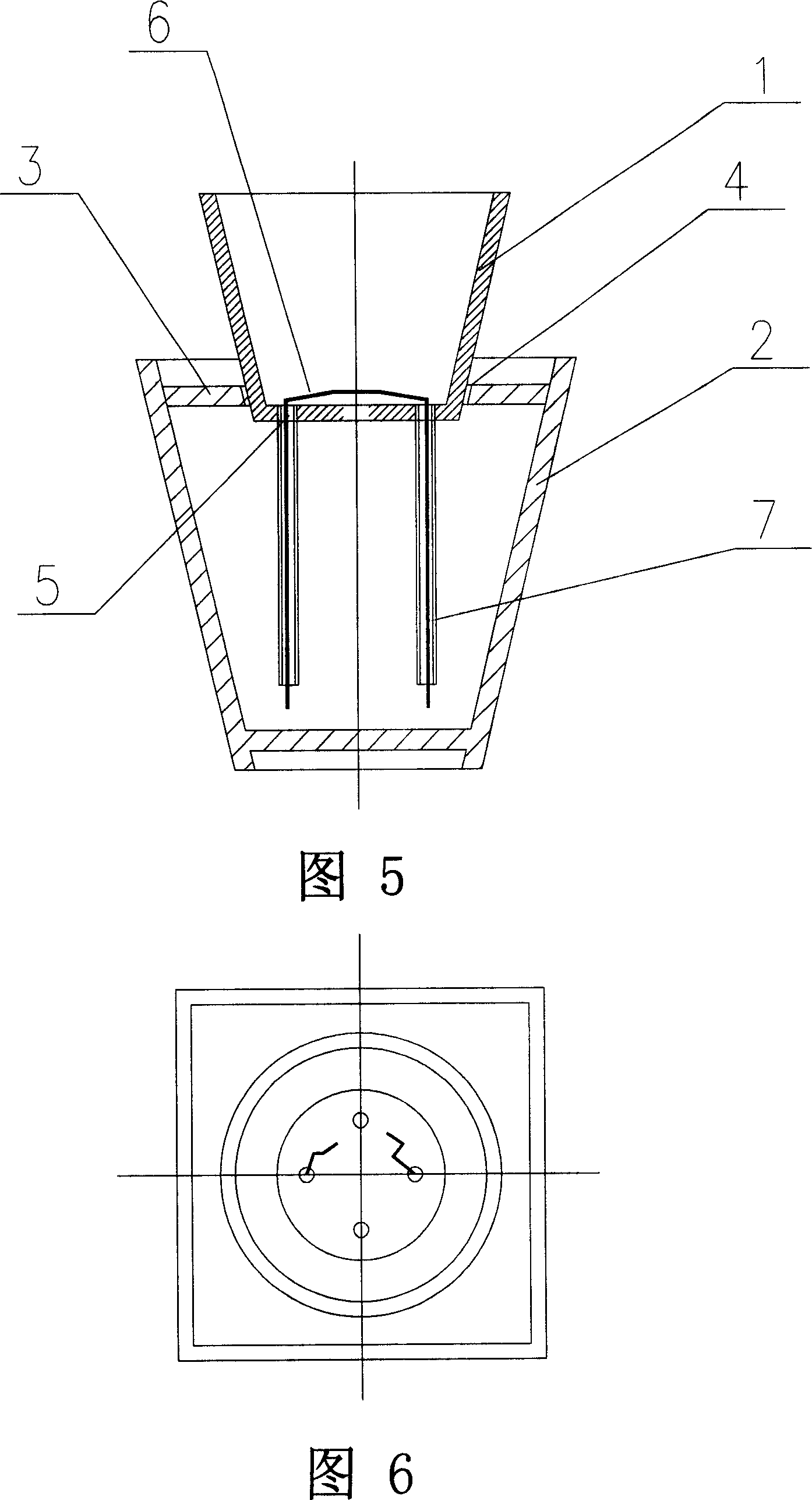

Degradable material and sand-fixation nursery stock cultivation stoup manufactured by the same

A technology of degradable materials and cultivation pots, applied in container cultivation, fertilizer mixtures, solid waste management, etc., can solve the problems of not being able to retain for a long time, easily volatile water, and difficult for plants to survive, so as to reduce water evaporation and prevent water loss , good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The degradable material of the present invention is used to make the sand-fixing seedling cultivation bowl, the weight percentage of the compound material of the sub-bowl is 80%, and the weight percentage of the compound agent is 20%, and the composition and weight ratio of the compound material are: 10 parts of kaolin, pearl 50 parts of rock, 10 parts of sawdust, 8 parts of bamboo cashmere.

[0040] The composition and weight ratio of the compound glue are: 1 part of starch, 14 parts of low free aldehyde urea-aldehyde resin, 2 parts of acrylic glue, 1 part of ceramic plasticizer, and 2 parts of liquid paraffin.

[0041] The weight percentage of the mother bowl compound is 67%, and the weight percentage of the compound is 33%. The composition and weight ratio of the compound are: 10 parts of kaolin, 30 parts of perlite, 20 parts of wood chips, 2 parts of compound fertilizer, 5 parts of paper fleece; the composition and weight ratio of the compound glue are: 1 part of wa...

Embodiment 2

[0045] Use the degradable material of the present invention to make the sand-fixing seedling cultivation bowl, the weight percentage of the compound material of the sub-bowl is 75%, the weight percentage of the described compound agent is 25%, and the composition and weight ratio of the described compound material are: kaolin 8 40 parts of perlite, 18 parts of chaff, 2 parts of compound fertilizer, and 7 parts of paper wool.

[0046] The composition and weight ratio of the compound glue are as follows: 1 part of starch, 16 parts of low free aldehyde urea-aldehyde resin, 3 parts of silicone acrylic grease, 3 parts of ceramic plasticizer, and 2 parts of liquid paraffin.

[0047] The weight percentage of the mother pot compound is 69%, the weight percentage of the compound is 31%, and the composition and weight ratio of the compound are: 15 parts of kaolin, 35 parts of perlite, 15 parts of wood chips, compound fertilizer 2 parts, 2 parts of bamboo wool; the composition and weight...

Embodiment 3

[0051] The degradable material of the present invention is used to make the sand-fixing seedling cultivation bowl, the weight percentage of the compound material of the sub-bowl is 76%, the weight percentage of the described compound agent is 24%, and the composition and weight ratio of the described compound material are: kaolin 10% 45 parts of perlite, 13 parts of chaff, 2 parts of compound fertilizer, 6 parts of bamboo cashmere.

[0052] The composition and weight ratio of the compound glue are: 1 part of water-absorbing starch, 18 parts of low-free aldehyde urea-aldehyde resin, 2 parts of acrylic glue, 1 part of plasticizer, and 2 parts of liquid paraffin.

[0053] The weight percentage of the mother bowl compound is 55%, and the weight percentage of the compound is 45%. The composition and weight ratio of the compound are: 8 parts of kaolin, 28 parts of perlite, 14 parts of chaff, and 2 parts of compound fertilizer , 3 parts of bamboo cashmere; the composition and weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com