Thermal insulation coating and preparation method thereof

A technology for thermal insulation and coating, which is applied to fire-resistant coatings, conductive coatings, antifouling/underwater coatings, etc., can solve the problems of durability and adhesion performance to be further improved, and achieves improved mechanical strength and simple preparation method. , the effect of improving film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

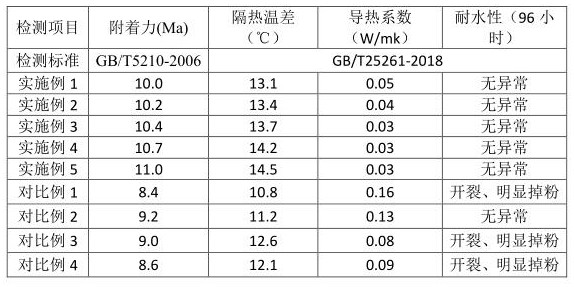

Examples

preparation example Construction

[0034] The preparation method of the modified carbon foam embedded with hollow nanoparticles includes: dispersing the foam carbon embedded with hollow nanoparticles in an organic solvent, and then adding vinyltriethoxysilane, 2-[ 3-(2H-Benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate, N-trimethylolmethacrylamide, glycidyl methacrylate, 1- Allyl-3-vinylimidazolium chloride salt, initiator, stirred and reacted at 70-80°C for 4-6 hours in an inert gas atmosphere, then centrifuged, washed with ethanol, dried, and ground through a 1200-1500 mesh sieve. The modified carbon foam with sealed pores embedded with hollow nanoparticles is obtained.

[0035] The carbon foam embedded with hollow nanoparticles, organic solvent, vinyltriethoxysilane, 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2- The mass ratio of methacrylate, N-trimethylol methacrylamide, glycidyl methacrylate, 1-allyl-3-vinylimidazole chloride salt, initiator is (3-5):( 20-30):(0.2-0.3):0.3:0.3:0.2:(0.1-0.3)...

Embodiment 1

[0046] Embodiment 1 provides a heat-insulating coating, which is characterized in that it is made of the following raw materials in parts by weight: 8 parts of foamed carbon embedded with hollow nanoparticles in modified sealed holes, 3 parts of hydrophilic molecular sieves, amino-terminated 30 parts of hyperbranched polybenzimidazole, 10 parts of sulfonated polybenzimidazole, 30 parts of inorganic filler, 2 parts of defoamer, 1 part of dispersant, and 10 parts of solvent.

[0047] The solvent is cyclohexanone; the dispersant is sodium hexametaphosphate; the defoamer is tributyl phosphate; the inorganic filler is double fly powder; the particle diameter of the inorganic filler is 1000 mesh; Amino-terminated hyperbranched polybenzimidazole is the third generation product.

[0048] The preparation method of the modified carbon foam embedded with hollow nanoparticles includes: dispersing the foam carbon embedded with hollow nanoparticles in an organic solvent, and then adding vin...

Embodiment 2

[0052] Embodiment 2 provides a kind of thermal insulation coating, its formulation and preparation method are basically the same as embodiment 1, the difference is that it is made of the following raw materials in parts by weight: modified sealed foam with hollow nanoparticles embedded Carbon 8.5 parts, hydrophilic molecular sieve 3.5 parts, amino-terminated hyperbranched polybenzimidazole 33 parts, sulfonated polybenzimidazole 12 parts, inorganic filler 33 parts, defoamer 2.5 parts, dispersant 1.5 parts, solvent 11 parts ; The carbon foam embedded with hollow nanoparticles, organic solvent, vinyltriethoxysilane, 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl] ethyl 2 -The mass ratio of methacrylate, N-trimethylol methacrylamide, glycidyl methacrylate, 1-allyl-3-vinylimidazolium chloride, initiator is 3.5:23:0.23: 0.3:0.3:0.2:0.15:0.012.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com