Method for preparing monodisperse high-crystallinity copper powder

A high crystallinity, monodisperse technology, applied in the field of preparation of copper powder for conductive paste, can solve the problems of ineffective control of the reaction process, broadening of powder particle size distribution, unbalanced reaction process, etc., to achieve cheap raw material sources, structure The effect of dense and well-developed crystal lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

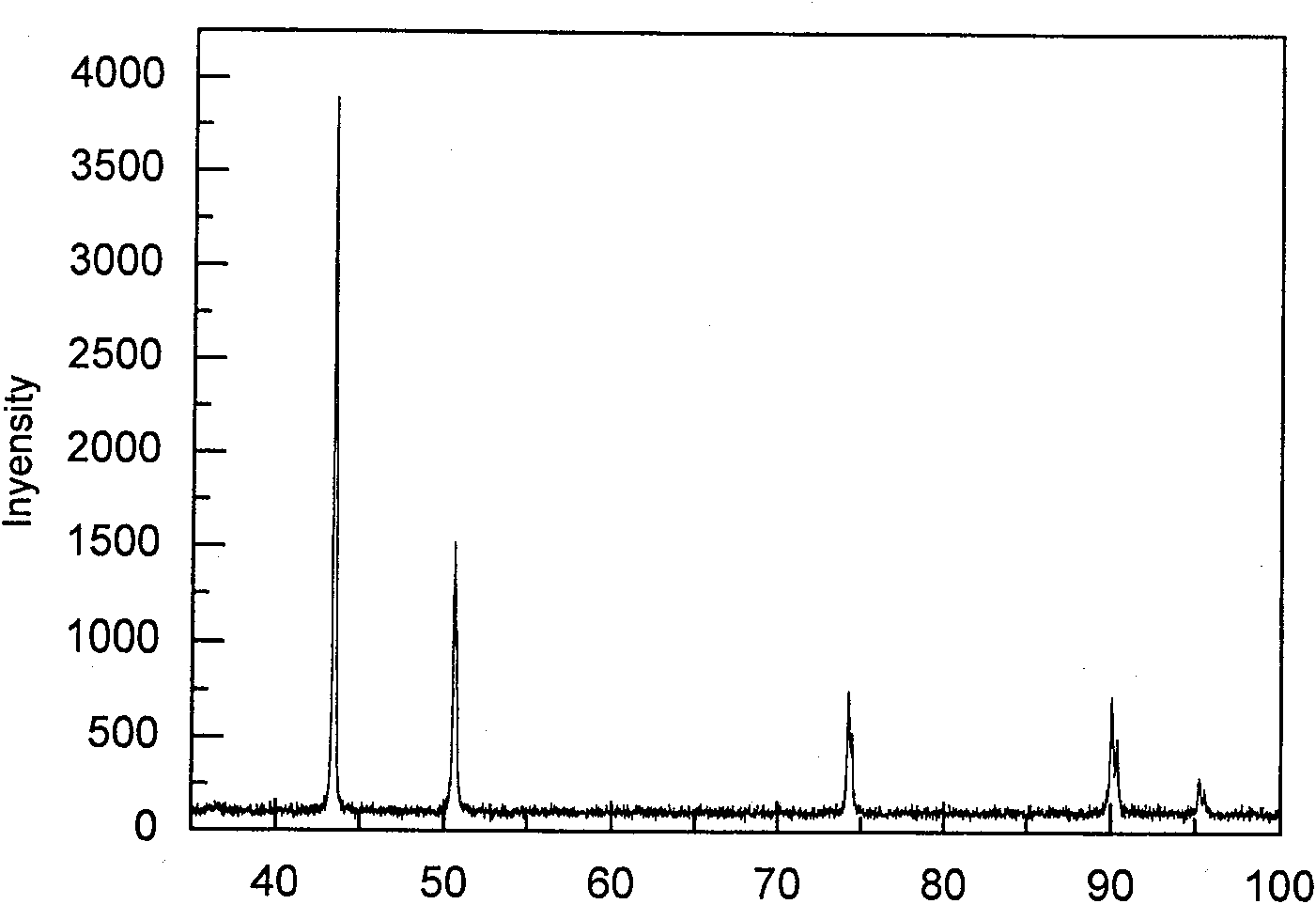

[0022] First prepare 0.5 L of alcohol-water solution of copper compound, wherein the addition amount of ethylene glycol is 0.5 mol, copper nitrate is 0.5 mol, then add 1 mol of sodium hypophosphite, sodium formate is added to the saturated amount, after mixing well, adjust the pH of the solution to 6.8°C, then raised to 95°C, introduced carrier gas Ar, the flow rate of the carrier gas was 200ml / min·L, and after 1 hour of heat preservation, the obtained product was separated from liquid to solid, washed, and dried in vacuum to obtain monodisperse and highly crystalline copper powder. The shape of the copper powder is spherical, and the average particle size is 3.2um. The X-ray pattern of copper powder is as follows figure 1 As shown, it can be seen from the figure that, except for the characteristic peak of copper, there is no other impurity phase, and the characteristic peak is narrow and sharp, indicating that the prepared copper powder grains are well developed and have hig...

Embodiment 2

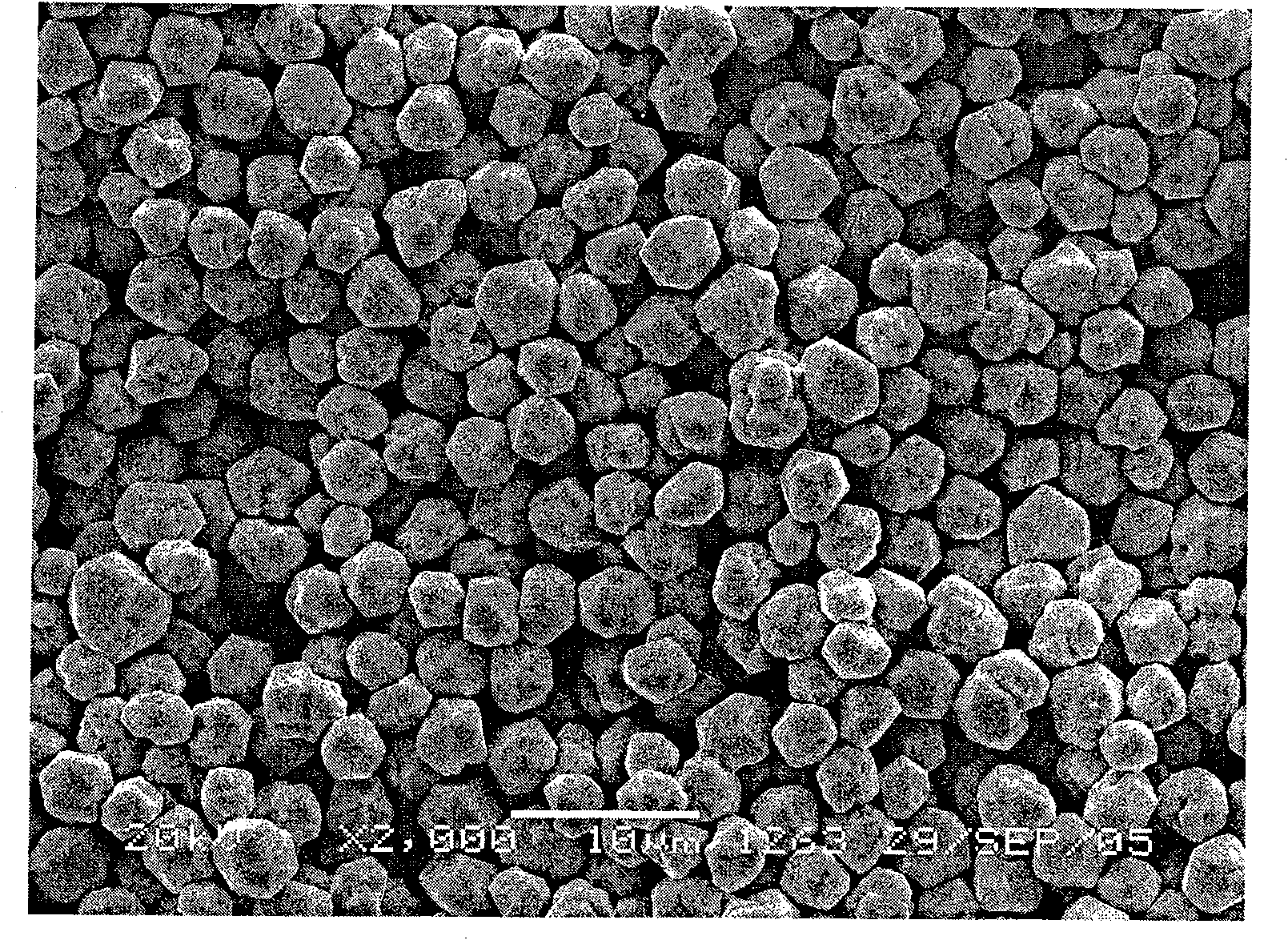

[0024] First prepare 0.5 L of alcohol-water solution of copper compound, wherein the addition amount of triethylene glycol is 0.5 mol, copper chloride is 0.5 mol, then add 1 mol of formaldehyde, sodium chloride is added to the saturated amount, after fully mixing, adjust the pH of the solution to 6.5, then the temperature was raised to 65°C, and the carrier gas N 2 , the flow rate is 100ml / min·L, after 2 hours of heat preservation, the obtained product is separated from liquid to solid, washed, and dried in vacuum to obtain monodisperse copper powder with high crystallinity. The shape of the copper powder is spherical, and the average particle size is 4.7um. Scanning electron microscope photos as image 3 shown.

Embodiment 3

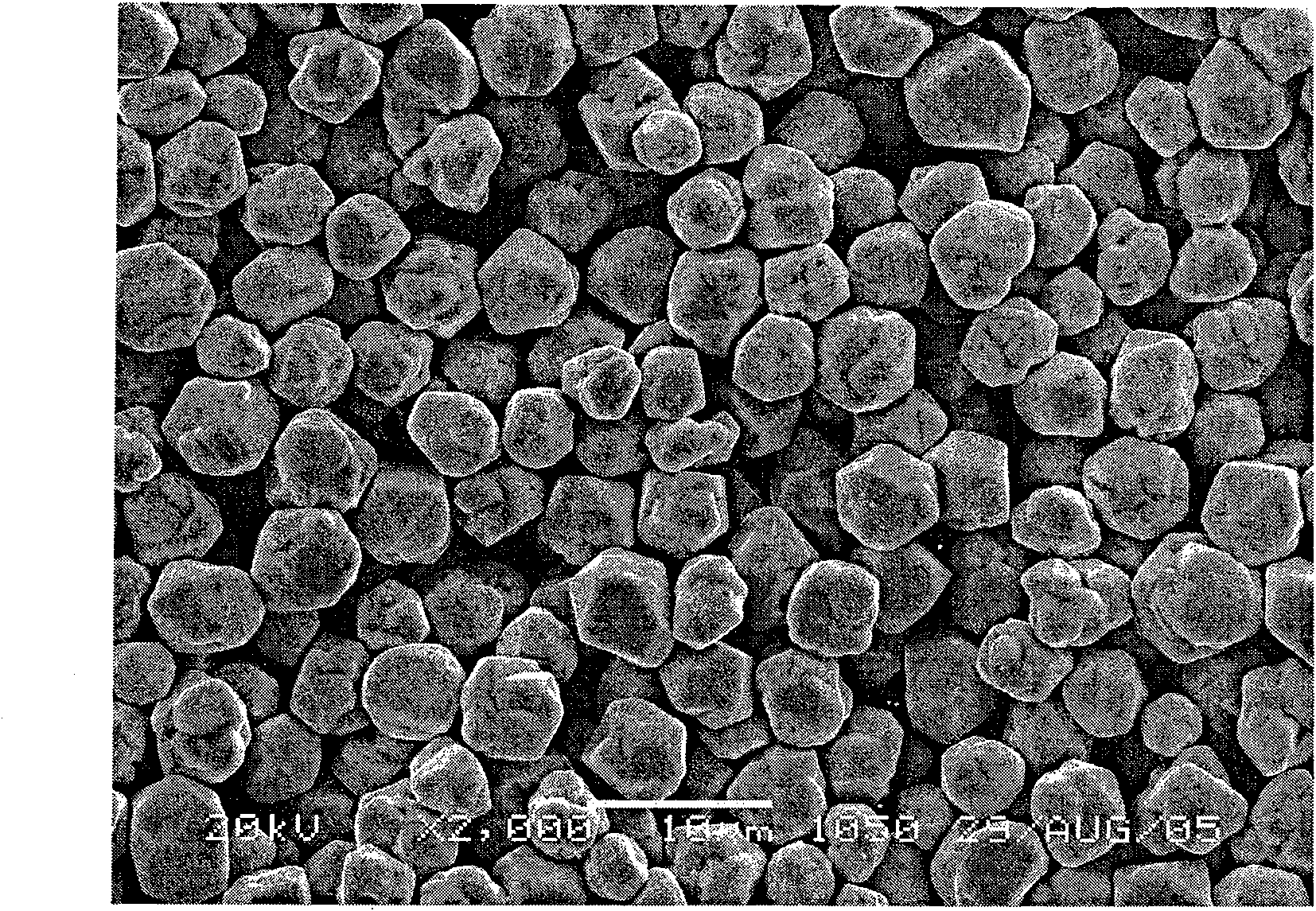

[0026] First prepare 0.5L of alcohol-water solution of copper compound, wherein the addition amount of 1,2-propanediol is 0.5mol / L, copper acetate is 0.25mol, then add 1mol of hydrazine hydrate, add sodium chloride to the saturated amount, and mix thoroughly, Adjust the pH of the solution to 7.2, then raise the temperature to 80°C, pass the carrier gas Ar, the flow rate of the carrier gas is 200ml / min·L, keep it warm for 3 hours, separate the liquid from the solid, wash it, and dry it in vacuum to obtain monodisperse High crystallinity copper powder. The shape of the copper powder is spherical, and the average particle size is 2.4um. Scanning electron microscope photos as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com