Process for preparing carbon nanotube cathode material

A carbon nanotube cathode and carbon nanotube technology, which are applied in cold cathode manufacturing, discharge tube/lamp manufacturing, electrode system manufacturing, etc., to achieve the effects of reducing production costs, improving display resolution, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

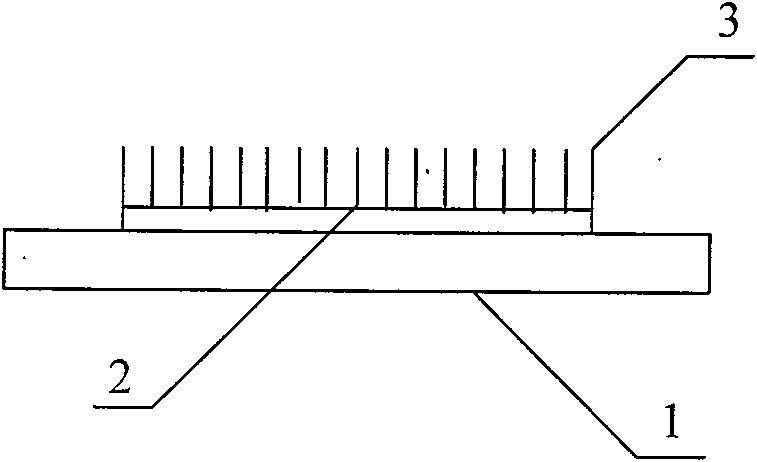

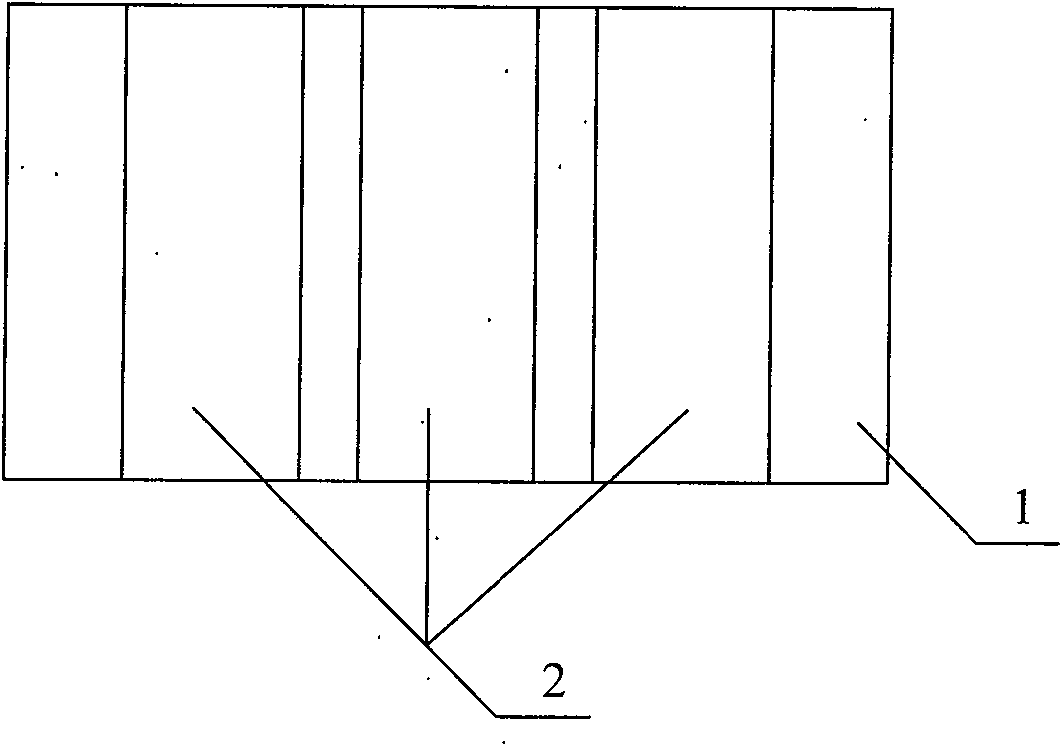

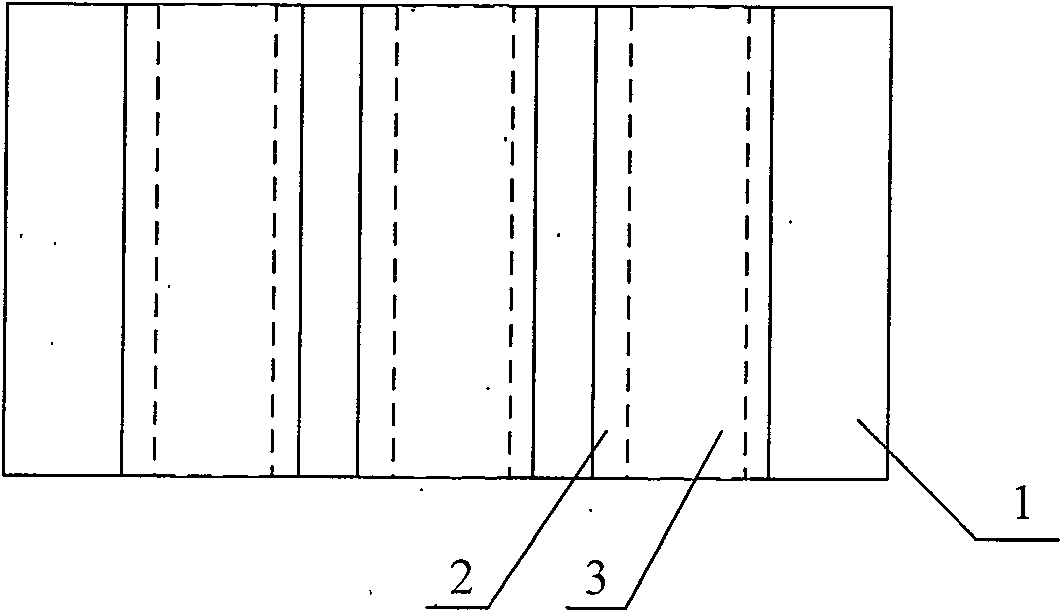

[0025] Such as figure 1 , 2 , 3, and 4, in order to understand and demonstrate the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

[0026] The present invention provides a manufacturing process of carbon nanotube cathode material, including the following manufacturing steps:

[0027] 1. Scribing of the cathode substrate glass (1): Scribing the whole flat glass;

[0028] 2. The making of the cathode conductive strip (2): vapor-depositing a layer of tin-indium oxide thin film layer on the cathode base glass (1); photolithography is carried out to the evaporated tin-indium oxide thin-film layer to form the cathode conductive strip (2) );

[0029] 3. Preparation of carbon nanotube powder materials: Purify carbon nanotube powder, remove impurities in the powder, and carry out discrete work of large groups of carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com