Compound sustained-release pellet tablet containing nifedipine and atenolol and preparation thereof

A technology for sustained-release pellets and sustained-release pellets, which is applied in the directions of medical preparations containing active ingredients, pill delivery, pharmaceutical formulations, etc., and can solve the problem of process stoppage, equipment damage, inability to press the drug-containing pellets into tablets, etc. problem, to achieve good mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

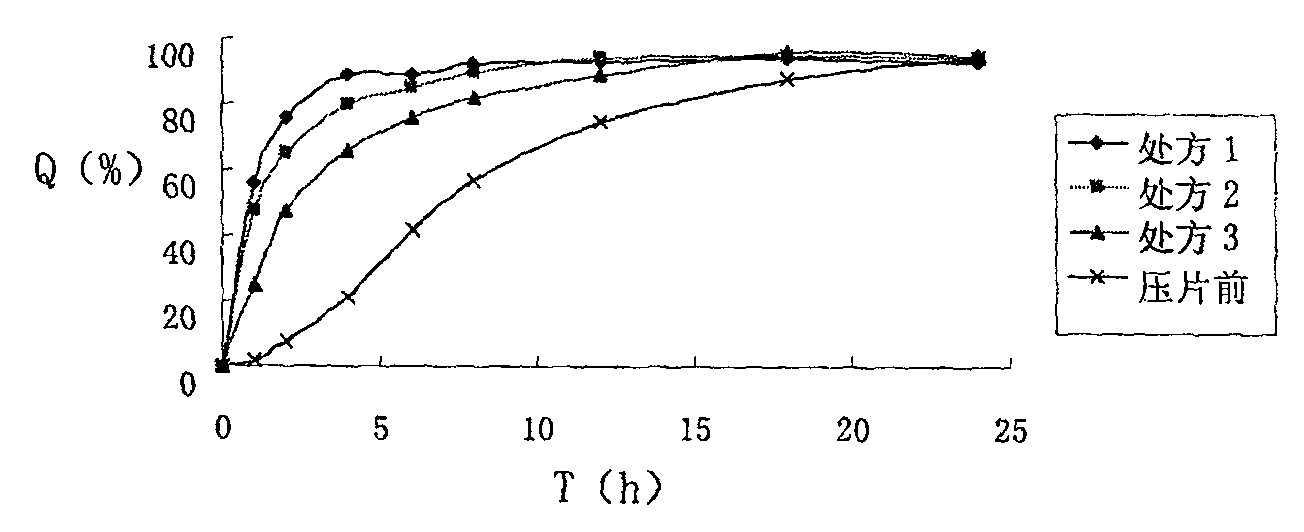

Embodiment 1

[0051] Weigh 5g atenolol, 5g microcrystalline cellulose and 3g tartaric acid, mix them evenly, use a 2% aqueous solution of povidone K30 as a binder to make a soft material, extrude and spheronize to prepare atenolol-containing pellet cores, sieve Take 30-40 mesh and set aside.

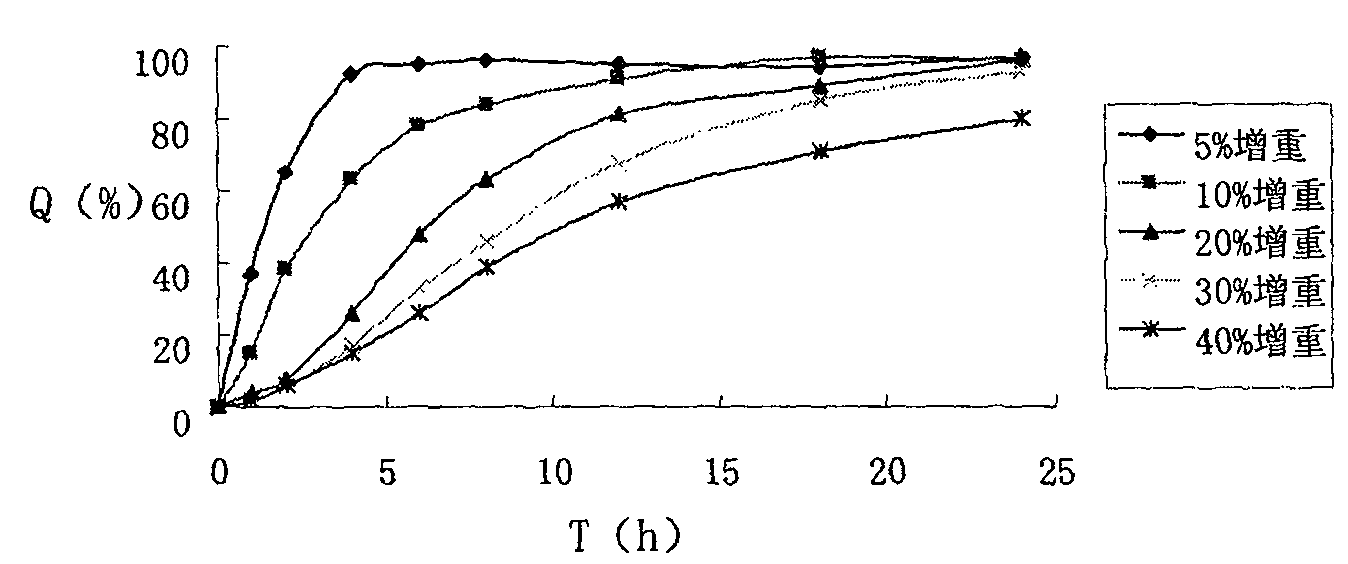

[0052] Weigh the above-mentioned 10g atenolol-containing pellets in a fluidized bed. Add 0.267g talc powder and 0.002g bright blue lake into 15ml water and mix and stir to obtain a suspension. Just before use, add 0.533g methyl methacrylate: butyl acrylate 1:1.5 polymer, 15ml water and 15ml ethanol. In the coating liquid, the wind speed, temperature and flow rate of the coating liquid are adjusted to ensure a good fluidization state, and the weight gain of the coating is about 8%. Atenolol sustained-release pellets are prepared with a drug content of 35.6%.

[0053] Weigh 10g of nifedipine and 20g of polyethylene glycol 6000 to prepare a solid dispersion. Weigh 10g of the above solid dispersion and 10g of...

Embodiment 2

[0059] Weigh 5g atenolol, 5g microcrystalline cellulose and 3g tartaric acid, mix them evenly, use a 2% aqueous solution of povidone K30 as a binder to make a soft material, and prepare atenolol-containing pellet cores by centrifugal granulation coating , Sieve 30-40 mesh for later use.

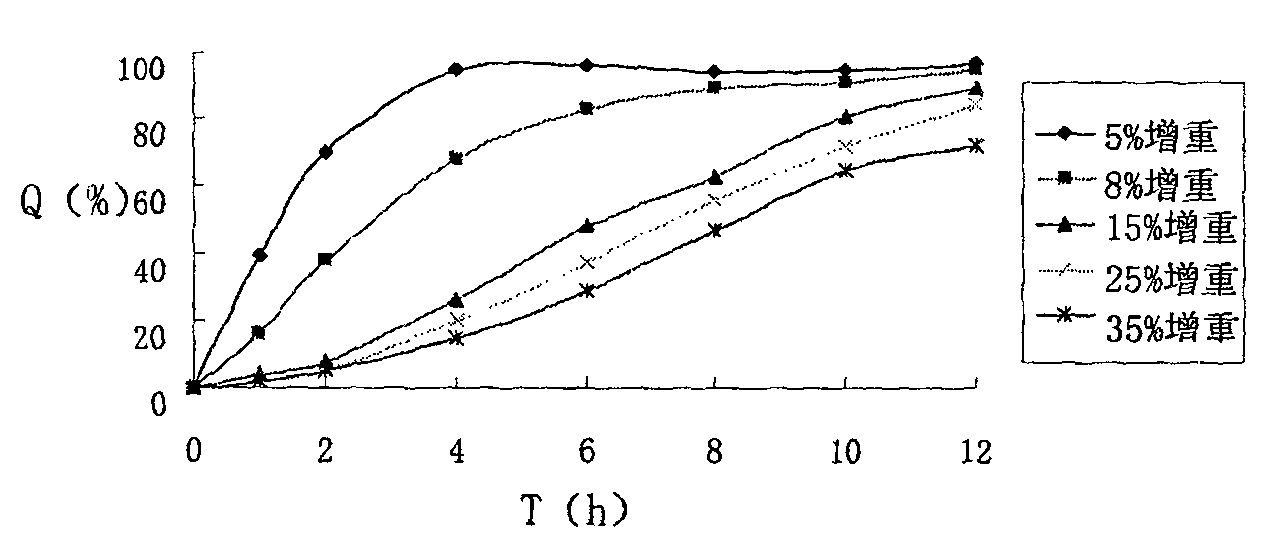

[0060] Weigh the above-mentioned 10g atenolol-containing pill core in a centrifugal granulation coating machine. Add 0.833g talc powder and 0.002g bright blue lake into 15ml water and mix and stir to obtain a suspension. Just before use, add 1.667g methyl methacrylate: ethyl acrylate 1:2 polymer, 15ml water and 15ml ethanol In the coating liquid, the wind speed, temperature and flow rate of the coating liquid are adjusted to increase the weight of the coating by about 25% to prepare atenolol sustained-release pellets with a drug content of about 30.77%.

[0061] Weigh 10g of nifedipine and 20g of polyethylene glycol 4000 to prepare a solid dispersion. Weigh 10g of the above solid dispersion and 1...

Embodiment 3

[0067] Weigh 5g of atenolol, 10g of microcrystalline cellulose and 3g of tartaric acid, mix them evenly, use a 2% aqueous solution of povidone K30 as a binder to make a soft material, and prepare atenolol-containing pellet cores in a fluidized bed in one step. Sieve 30-40 mesh for later use.

[0068] Weigh the above-mentioned 10g atenolol-containing pellets in a fluidized bed. Add 0.5g of talc and 0.002g of bright blue lake into 15ml of water and mix and stir to obtain a suspension. Just before use, add 1g of methyl methacrylate: butyl acrylate 1:2 polymer, 15ml of water and 15ml of ethanol. In the coating liquid, the wind speed, temperature and flow rate of the coating liquid are adjusted to ensure a good fluidization state, and the weight gain of the coating is about 15% to prepare atenolol sustained-release pellets with a drug content of 24.15%.

[0069] Weigh 10g of nifedipine and 40g of polyethylene glycol 6000 to prepare a solid dispersion. Weigh 10g of the above solid dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com