Pt/Ti metal membrane patterning technique

A technology of metal thin film and thin film graphics, which is applied in the fields of metal thin film patterning that is not easy to be etched, titanium metal thin film patterning, and platinum, and can solve problems such as low product qualification rate, graphic deformation, and product surface contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

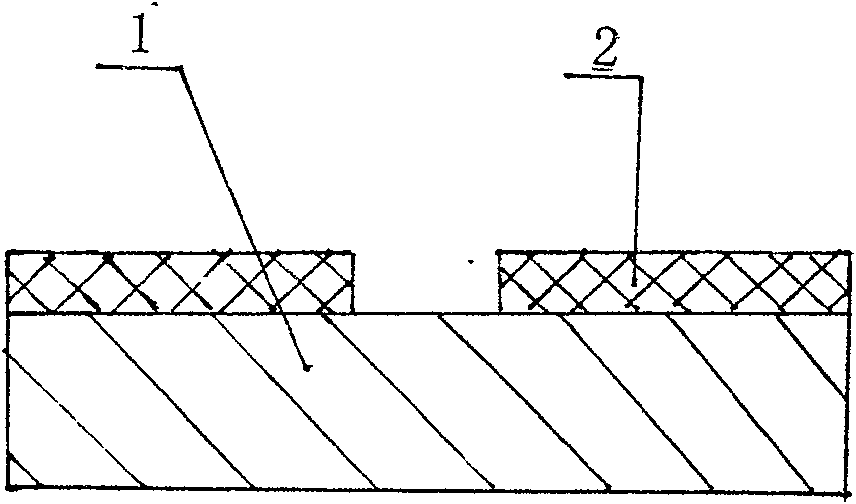

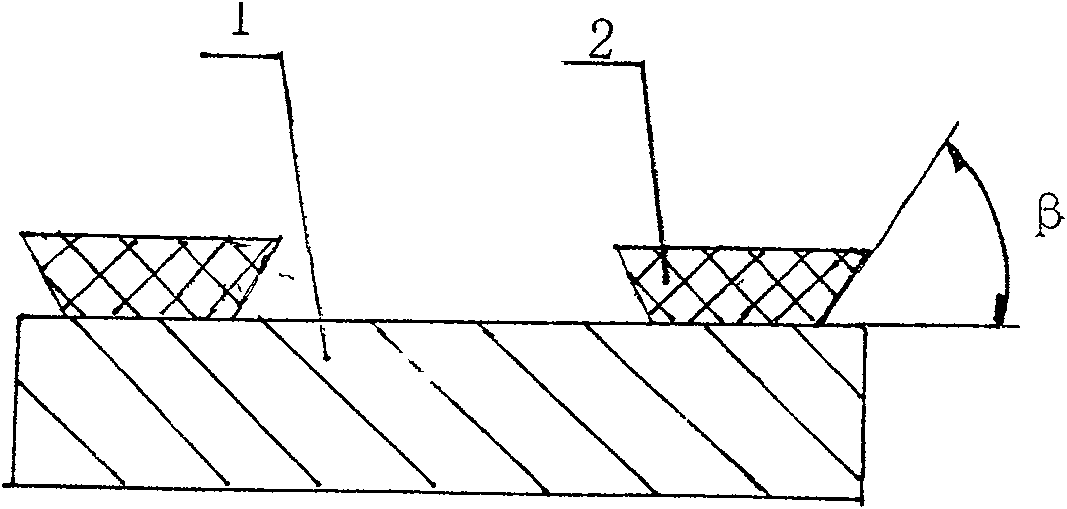

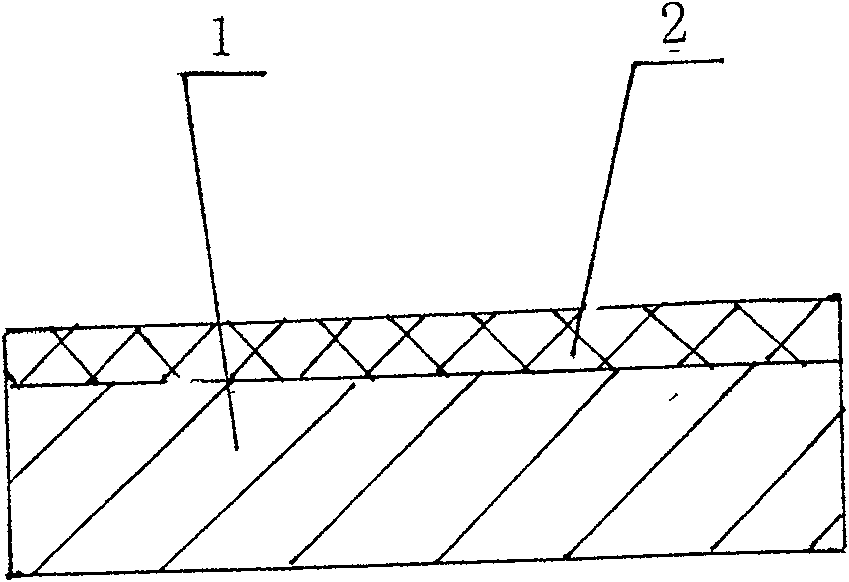

[0014] refer to Figure 6 , the concrete technological process of the present invention is: A, wash sheet, at first use detergent ultrasonic cleaning silicon chip 5 minutes, initially remove the organic dirt on silicon chip surface; Use acetone ultrasonic cleaning silicon chip 5 minutes again, clean silicon chip Impurities and dirt; Finally, soak in absolute ethanol for 3 minutes to completely remove the remaining impurities in the silicon wafer. B. Blow dry treatment, put the clean silicon wafer on the filter paper, and use nitrogen gas to dry the residual liquid on the surface of the silicon wafer through an air gun. C. Drying treatment, put the dried silicon wafer into a petri dish, put the petri dish into an oven, bake at 85°C for 5 minutes, and then take it out. D. Glue, refer to image 3 , Install the silicon wafer on the pallet of the homogenizer, and under the condition that the speed of the homogenizer is 4000 rpm, apply the photoresist 2 evenly on the silicon wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com