ITO etching solution for TFT-LCD display screen and preparation method

A technology of etching solution and display screen, which is applied in the direction of chemical instruments and methods, surface etching composition, etc., can solve the problems of difficult control of etching precision, severe etching reaction, high cost of etching solution, etc., and achieve excellent anti-corrosion effect and excellent production process Simple and satisfying technical process and process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] An ITO etching solution for TFT-LCD display screen, comprising the following components by weight percentage: 14wt% sulfuric acid, 3wt% ammonium sulfate, 1wt% 2-mercaptoimidazole, 0.1% surfactant, 0.05 wt% % defoamer, balance water.

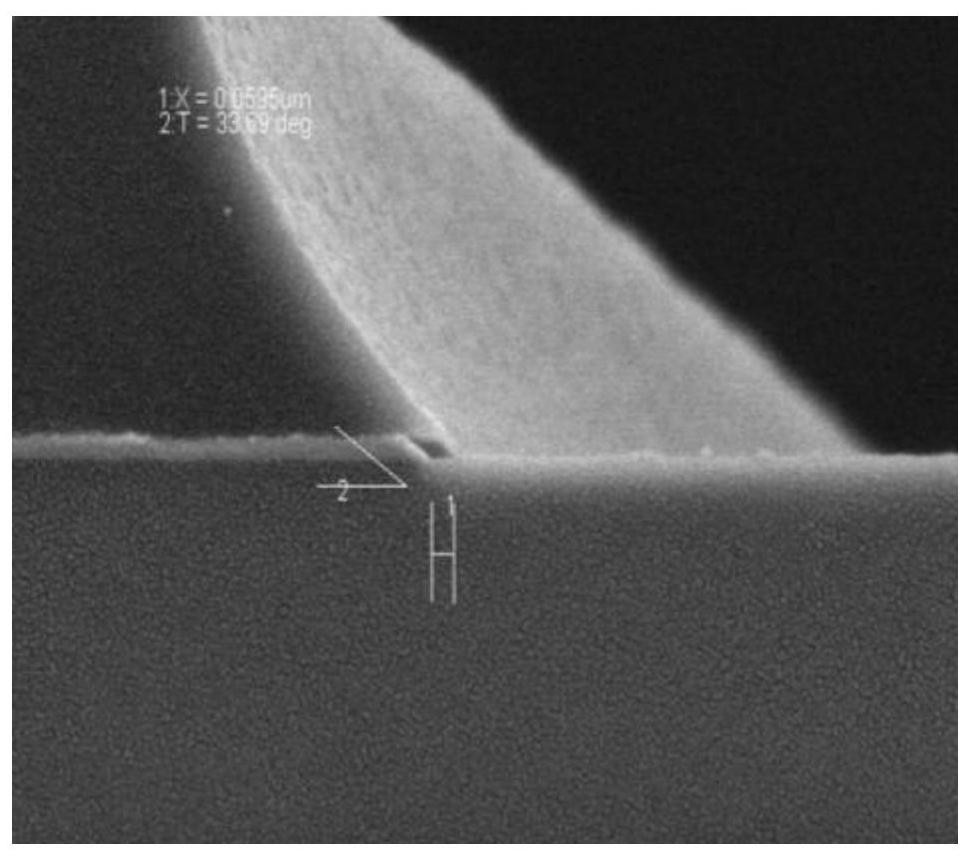

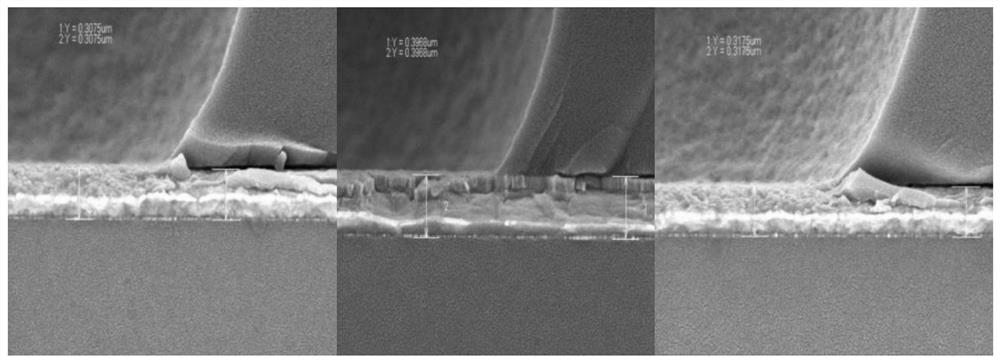

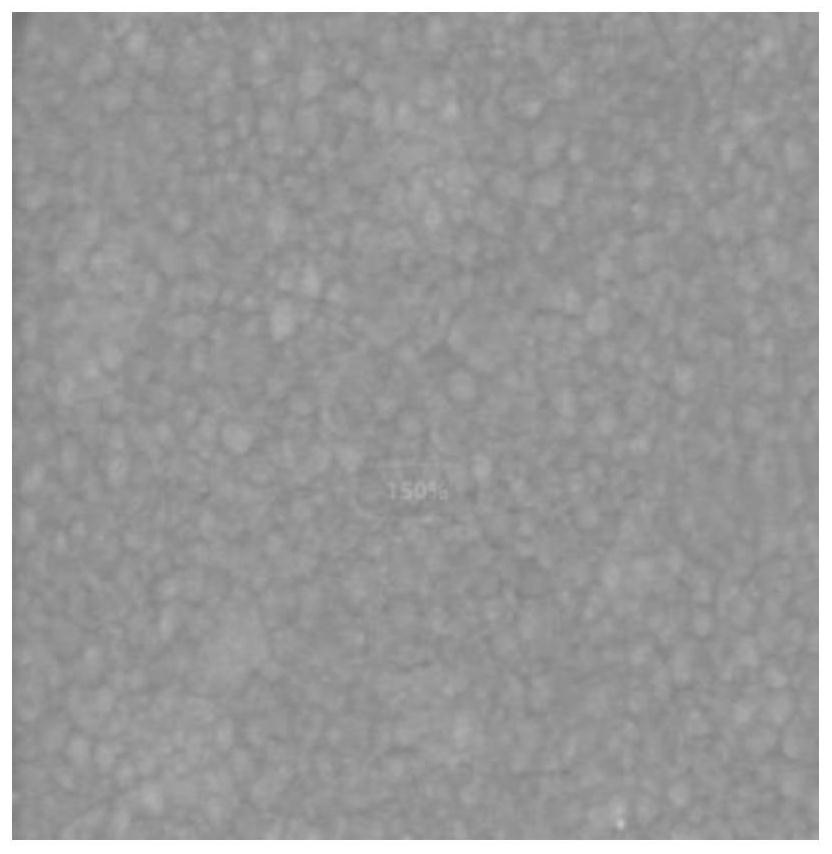

[0028] The etching object of the etching solution is ITO film, the etching time is 50s, and the etching temperature is 40℃; the etching results are as follows figure 1 As shown, the unilateral CD after etching is 0.0595um, and the slope angle of ITO is 33°; figure 2 Shown is the result of etching Mo, Al, and Cu by the etching solution, the etching time is 600s, the etching temperature is 40 °C, and the etching solution does not corrode the Mo, Al, and Cu metal layers; image 3 Shown is the result of etching the Cu glass sheet for 600 s with the etching solution, and no pitting is found.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com