Thermal transfer in-mould decoration and preparation method thereof

A technology of thermal transfer printing and decorations, which is applied in special decorative structures, printing of special varieties of printed matter, decorative art, etc., to achieve the effects of high color saturation, firm adhesion, and overcoming high temperature impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0027] one. Production of Thermal Transfer Coated Films

[0028] 1. Corona treatment on one side of Dupont 25um BOPET film (carrier film) to a surface tension of 48 dynes or more;

[0029] 2. Dilute KP-1153 silicone resin (Shanghai Kaiping Resin Co., Ltd.) with butanone and toluene (the mass ratio of butanone and toluene is 1:1), and coat it on the surface of BOPET to form a uniform silicone resin coating , the coating amount is 4g per square meter; then, at 180°C, cure for 6 seconds;

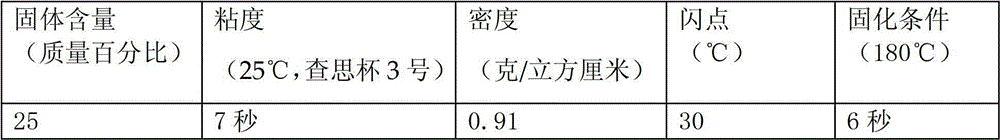

[0030] The typical physical properties of silicone resin diluted with methyl ethyl ketone and toluene are shown in Table 1.

[0031] Table 1

[0032]

[0033] 3. The mixed ink of gravure printing ink acrylic resin (Japan DIC) and polyurethane ink ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com