Fabricating method for semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting device performance, poor adhesion, etc., and achieve the effect of enhancing stability and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

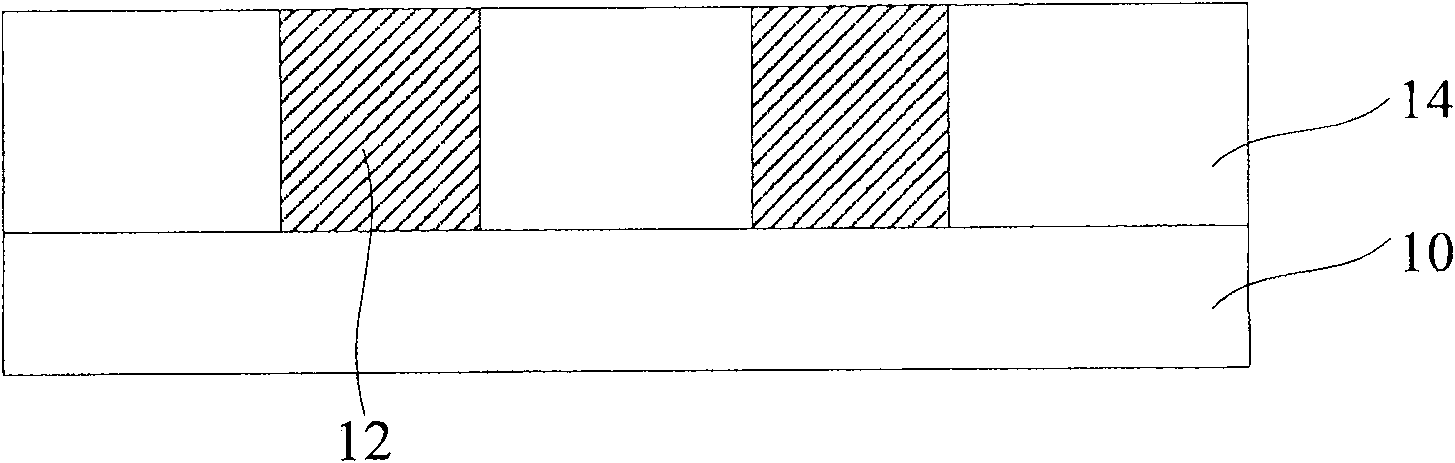

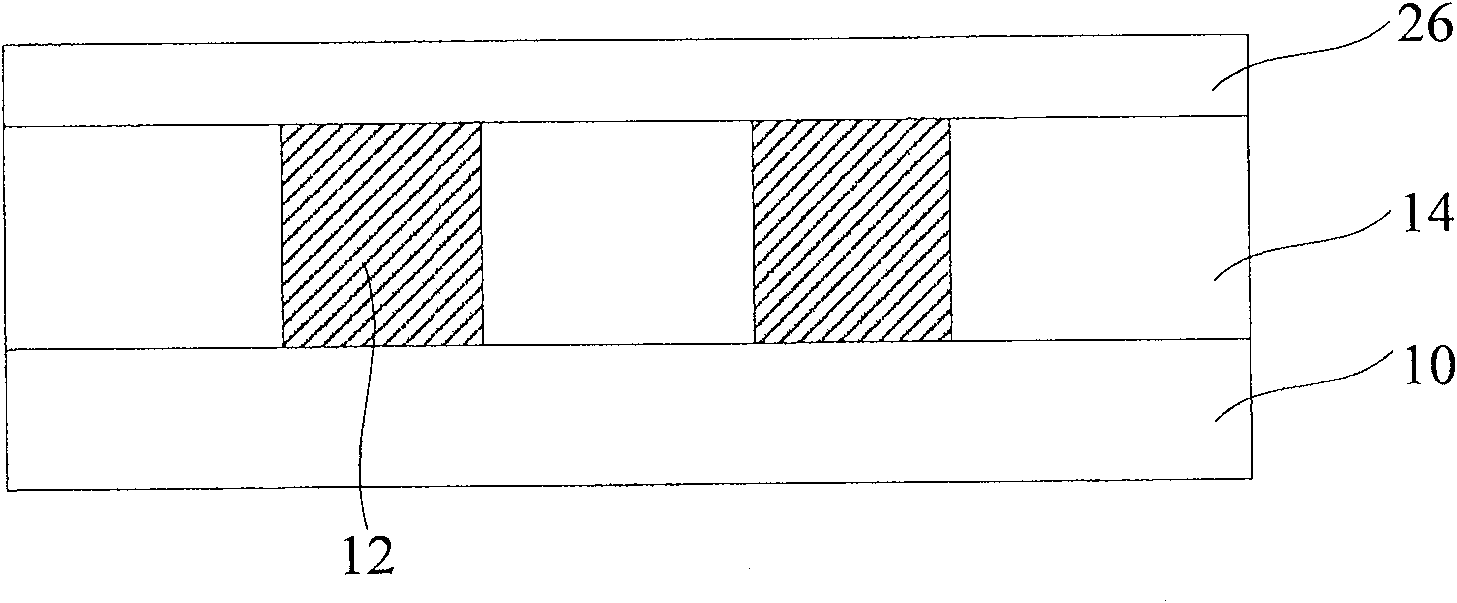

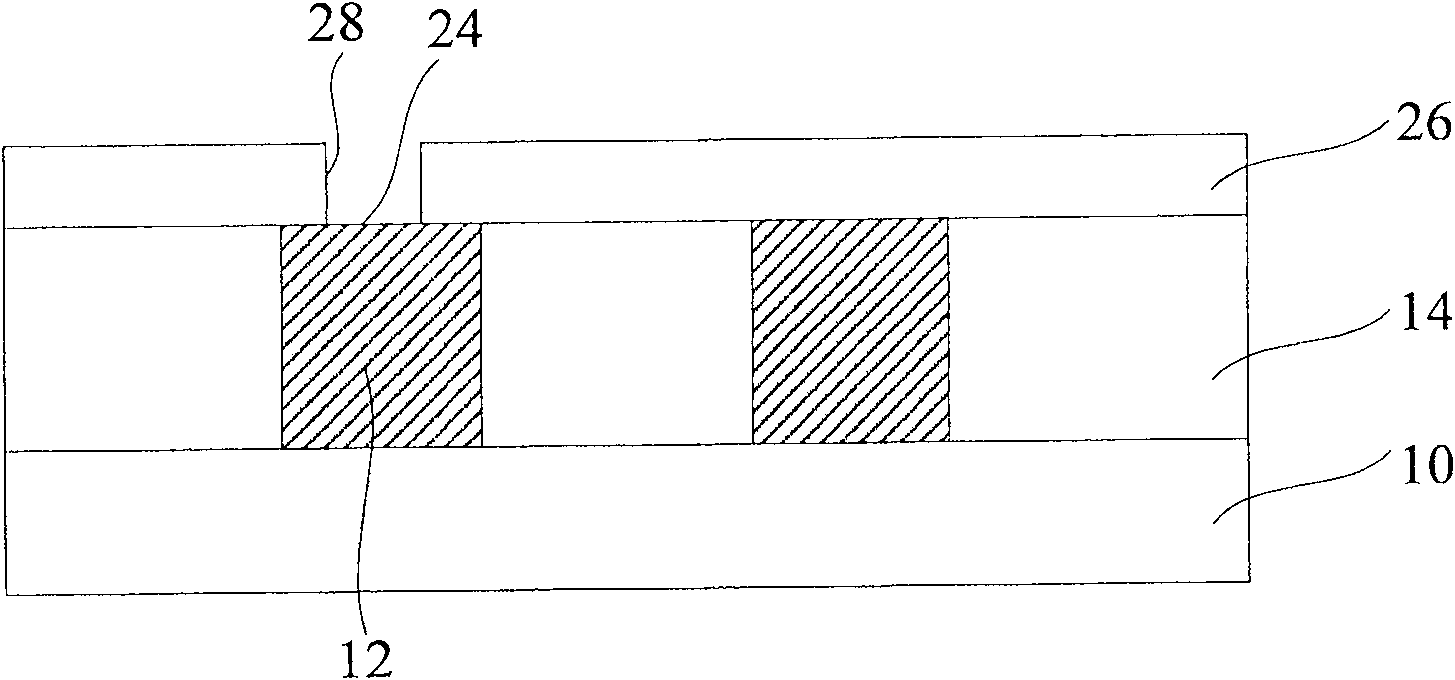

[0048] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] In the method of the present invention, before the photoresist layer is spin-coated on the aluminum metal layer, a barrier layer is first formed on the aluminum metal layer, then a photoresist layer is spin-coated on the barrier layer, and the patterned The photoresist layer forms a metal interconnection line pattern or a lead pad pattern; then etching removes the barrier layer and the aluminum metal layer not covered by the metal interconnection line pattern or the lead pad pattern to form a metal interconnection made of aluminum wire or lead pad. By forming a barrier layer between the photoresist layer and the aluminum metal layer, the photoresist layer can be prevented from diffusing into the grain gap of the aluminum metal layer, thereby reducing or eliminating metal residues caused thereby.

[0050] Figure 8 It is a flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com