Surface treatment method for electrolytic copper foil coating excellent in chemical resistance and cohesive force

A technology of electrolytic copper foil and chemical resistance, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of unsatisfactory copper foil acid resistance degradation rate, inconvenient operation, etc., and achieve favorable The effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

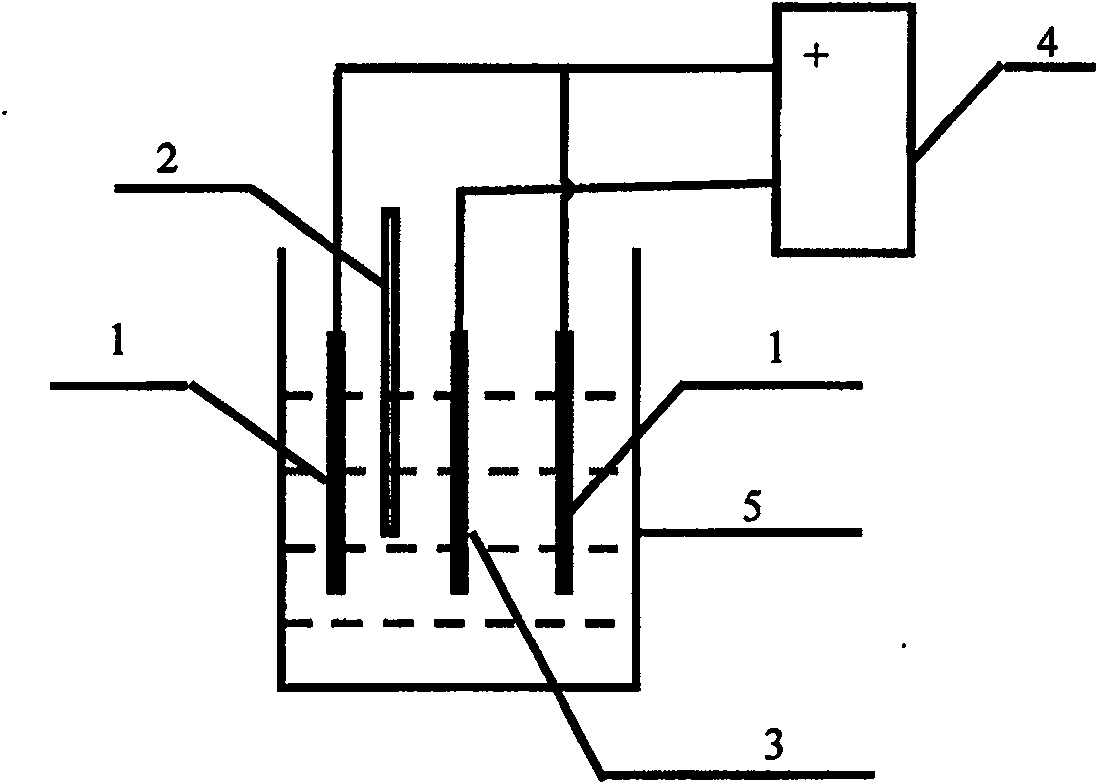

Method used

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: In the electrolytic copper foil coating in this embodiment, the mass percentage of Zn is 65-75%, the mass percentage of Ni is 20-30%, and the mass percentage of Sn is 3-7% %.

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass percentage of Zn in the electrolytic copper foil coating is 75%, the mass percentage of Ni is 22%, and the mass percentage of Sn is 3% %.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the mass percentage of Zn in the electrolytic copper foil coating is 70%, the mass percentage of Ni is 25%, and the mass percentage of Sn is 5% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com