Method for producing wide and thick superfine-grain hot-rolled plate

A technology of ultra-fine grains and production methods, applied in metal rolling, metal rolling, rolling mill control devices, etc., to achieve the effect of increasing the phase deformation nucleation rate, simple chemical composition, and reasonable yield-strength ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

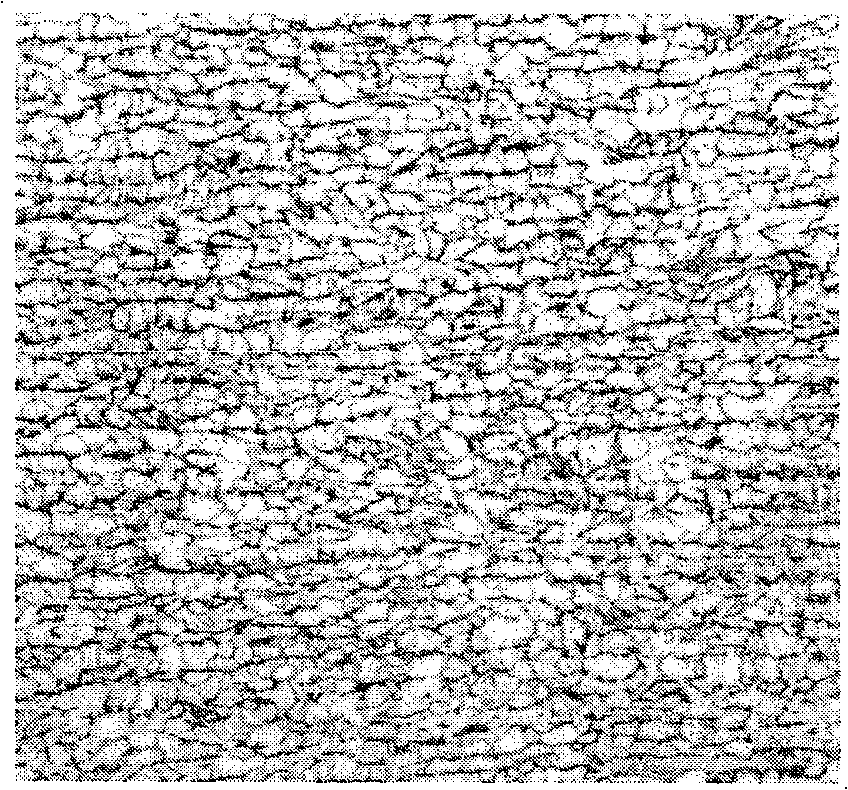

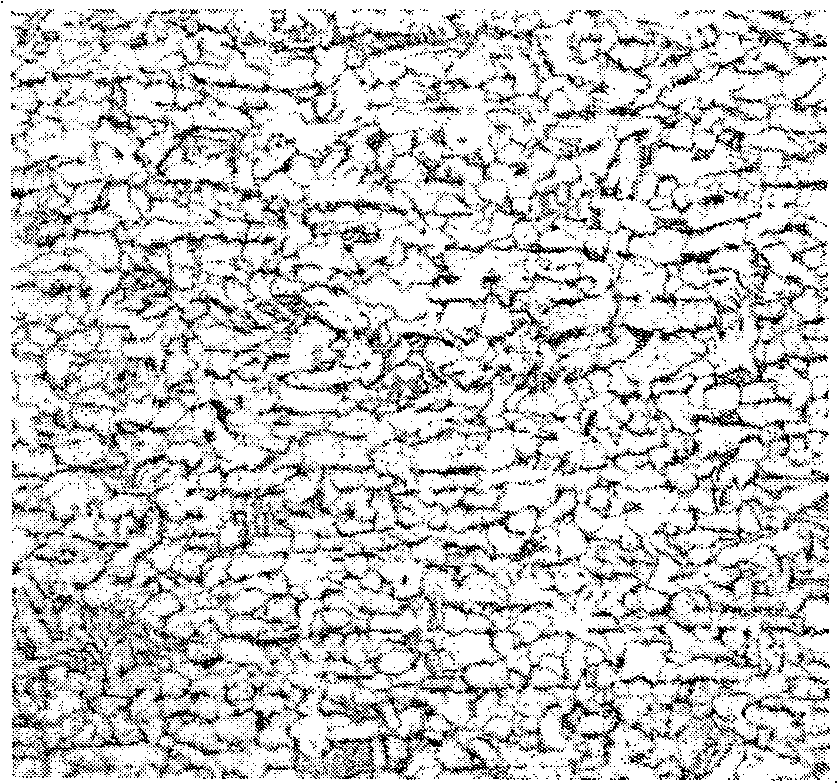

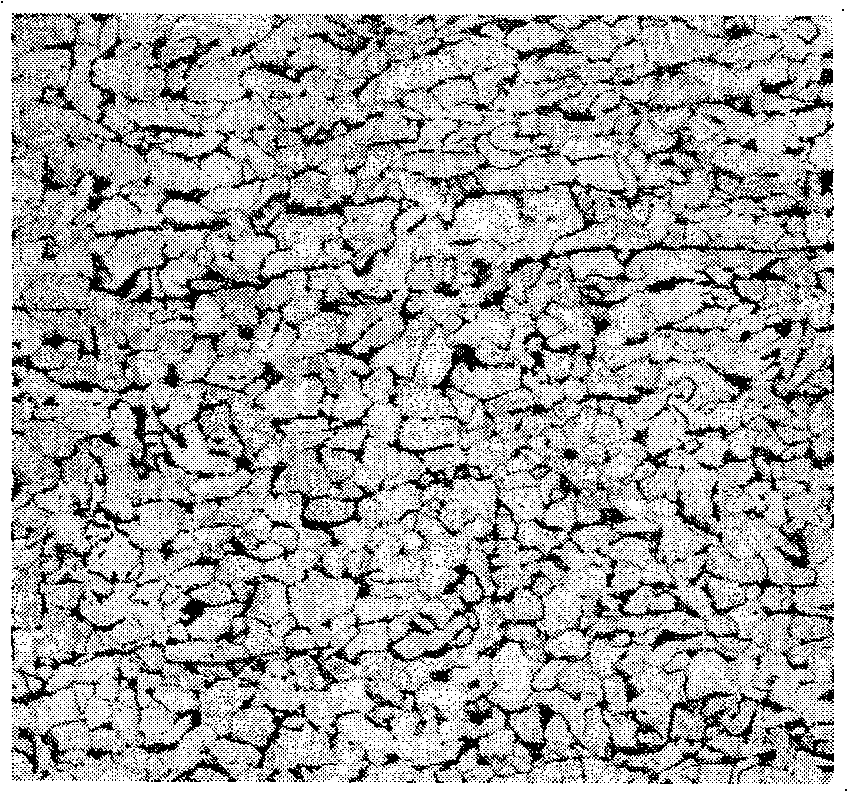

Image

Examples

Embodiment Construction

[0023] In order to reduce production costs and improve economic benefits, the invention adjusts and optimizes the chemical composition of common SS400, so that the strength of the steel plate is greatly improved. In order to reduce processing and welding deterioration, and at the same time properly achieve the purpose of solid solution strengthening, adjust C to 0.12-0.18%. In order to make Si play a role of solid solution strengthening and avoid deterioration of the surface properties of the steel plate, Si is adjusted to 0.12-0.25%. Mn can reduce Ar 3 The transformation point and the effect of expanding the austenite phase region are helpful for grain refinement and increased strength. At the same time, considering that it can improve the strength-ductility balance, the Mn is adjusted to 0.70-1.30%. According to the requirements of ultra-fine grain steel, the content of P and S is appropriately reduced, and the economical cleanliness of steel is achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com