Preparing process of nano gamma-alumina powder with intraparticle mesoporous structure

A kind of aluminum oxide nanometer and internal mesopore technology, which is applied in the direction of aluminum hydroxide preparation, alumina/hydroxide preparation, nanostructure manufacturing, etc., to achieve the effect of wide source, low energy consumption and cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: under the magnetic stirring of 1300r / min, the concentration that will contain 4.5wt% polyethylene glycol (PEG) 400 is 0.3mol / LAlCl 3 Add the solution of the same volume as the aluminum salt A solution to the concentration of 0.6mol / L ammonium bicarbonate B solution (pH is 9.3) containing 4.6wt% polyethylene glycol (PEG) 2000 at a speed of 300 drops / minute, After the titration is completed, continue to stir for 0.5 h; centrifuge, wash 3 times with secondary water and 3 times with ethanol, dry at 80° C. for 4 h, remove surface water, and obtain a dry powder. Add the obtained dry powder into 80ml of n-butanol, after ultrasonic dispersion, reflux for 2h, distill and remove the n-butanol-water azeotrope at 93°C, when the fraction temperature rises to the boiling point of n-butanol at 117°C, After stopping the distillation and continuing to reflux for 2 h, the n-butanol was recovered by distillation under reduced pressure to obtain a loose powder.

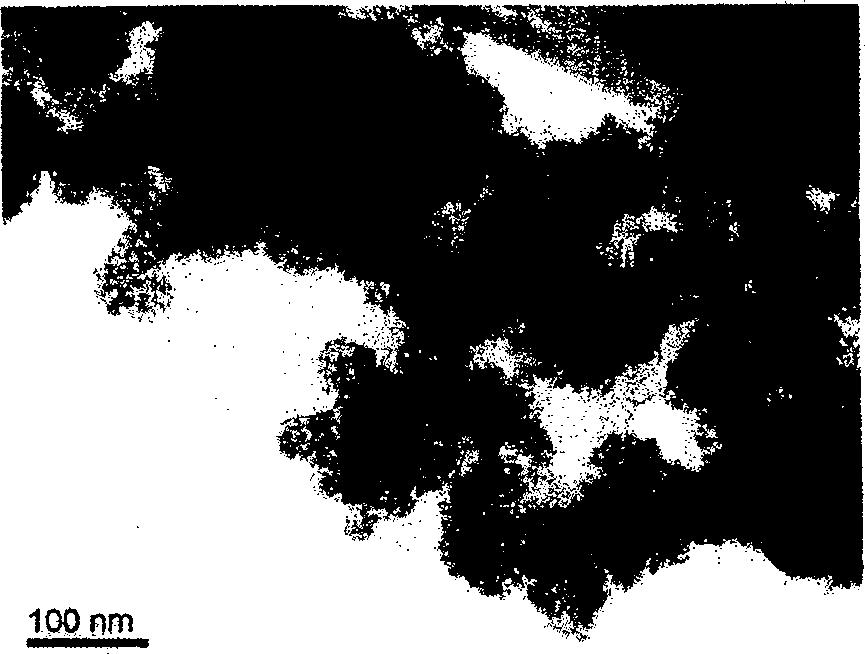

[0027] Calc...

Embodiment 2

[0028] Embodiment 2: Under the magnetic stirring of 1000r / min will contain the Al of 4.5wt% PEG400 3+ The concentration is 0.30mol / L (AlCl 3 : NH 4 Al(SO 4 ) 2 =1:1 molar ratio) solution as the aluminum salt A solution is added into an equal volume of ammonium bicarbonate B solution (pH is 9.3) containing 4.6wt% PEG2000 with a concentration of 0.60mol / L as the aluminum salt A solution at a rate of 250 drops / minute, After the titration is completed, continue to stir for 0.5 h; centrifuge, wash 3 times with secondary water and 3 times with ethanol, dry at 80° C. for 4 h, remove surface water, and obtain a dry powder. Add the obtained dry powder into 80ml of n-butanol, after ultrasonic dispersion, reflux for 2h, distill and remove the n-butanol-water azeotrope at 93°C, when the fraction temperature rises to the boiling point of n-butanol at 117°C, After stopping the distillation and continuing to reflux for 2 h, the n-butanol was recovered by distillation under reduced pressu...

Embodiment 3

[0030] Embodiment 3: under the magnetic stirring of 1300r / min will contain the Al of 8wt% PEG400 3+ The concentration is 0.4mol / L (AlCl 3 : NH 4 Al(SO 4 ) 2 =1:1) solution as the aluminum salt A solution is added at a rate of 350 drops / min to 2 times the volume of ammonium bicarbonate B solution (pH is 9.3) containing 8wt% PEG2000 with a concentration of 0.40mol / L, and the titration is completed After that, continue to stir for 0.5h; centrifuge, wash with secondary water for 3 times, add the obtained precipitate to 80ml of n-butanol, after ultrasonic dispersion, reflux for 2h, and distill to remove 93°C n-butanol-water For azeotrope, when the distillate temperature rises to 117°C, the boiling point of n-butanol, stop the distillation, continue to reflux for 2 hours, recover n-butanol by distillation under reduced pressure, and obtain a loose powder.

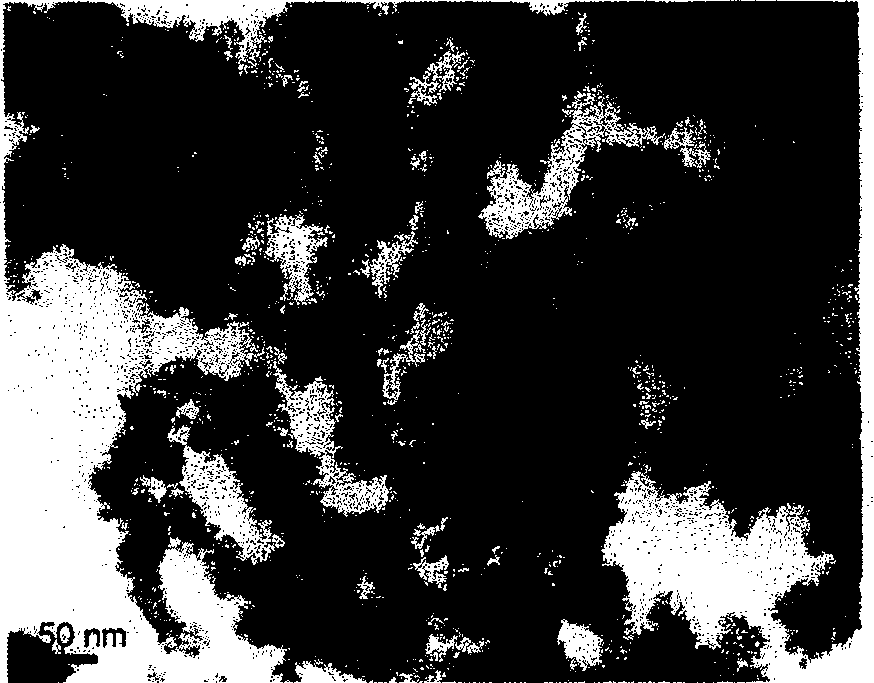

[0031] Calcined at 880°C for 2.5 hours to obtain γ-Al 2 o 3 product, its particle morphology see image 3 . The surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com