Horizontal broacher

A horizontal, bed-body technology, used in broaching, broaching devices, metal processing, etc., can solve the problems of long broach return time and reduced broaching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

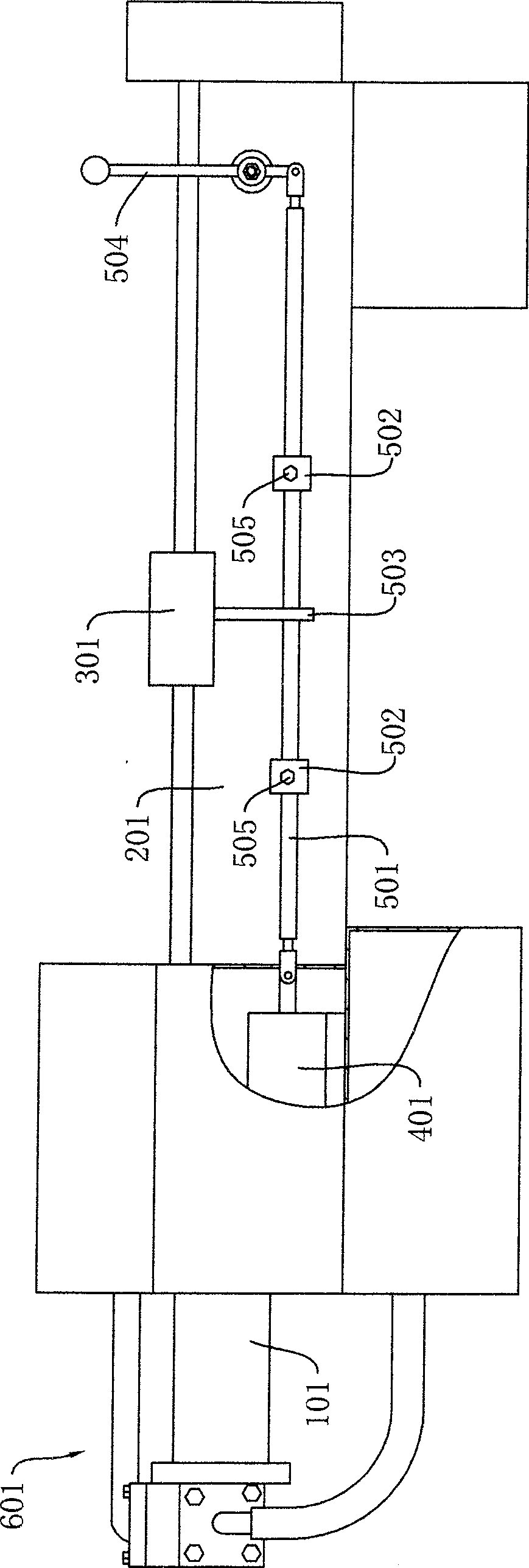

[0020] A horizontal broaching machine, such as figure 1 As shown, the hydraulic cylinder 101 and the manual reversing valve 401 are installed on the bed body 201, the piston rod of the hydraulic cylinder 101 and the broach are fixedly connected together through the chuck, and the chuck and the sliding seat that can slide along the guide rail of the bed body 201 301 fixed connection. The differential valve 601 is fixedly connected to the rodless cavity end of the cylinder body of the hydraulic cylinder 101 .

[0021] An operating device is provided between the sliding seat 301 and the valve stem of the manual reversing valve 401, and the specific structure is as follows: the joystick 501 is connected with the valve stem of the manual reversing valve 401, and is hinged with the operating handle 504 at its other end , the operating handle 504 is hinged with the bed body 201 at an appropriate position. The joystick 501 and the manual reversing valve 401 are preferably hinged, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com