Electromagnetic actuating device

A control device and electromagnetic technology, applied in the direction of electromagnet, valve device, valve operation/release device, etc., can solve the problems of complex manufacturing and magnetic force reduction, and achieve the effects of simplified manufacturing, simple cost, and avoiding the weakening of the magnetic circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

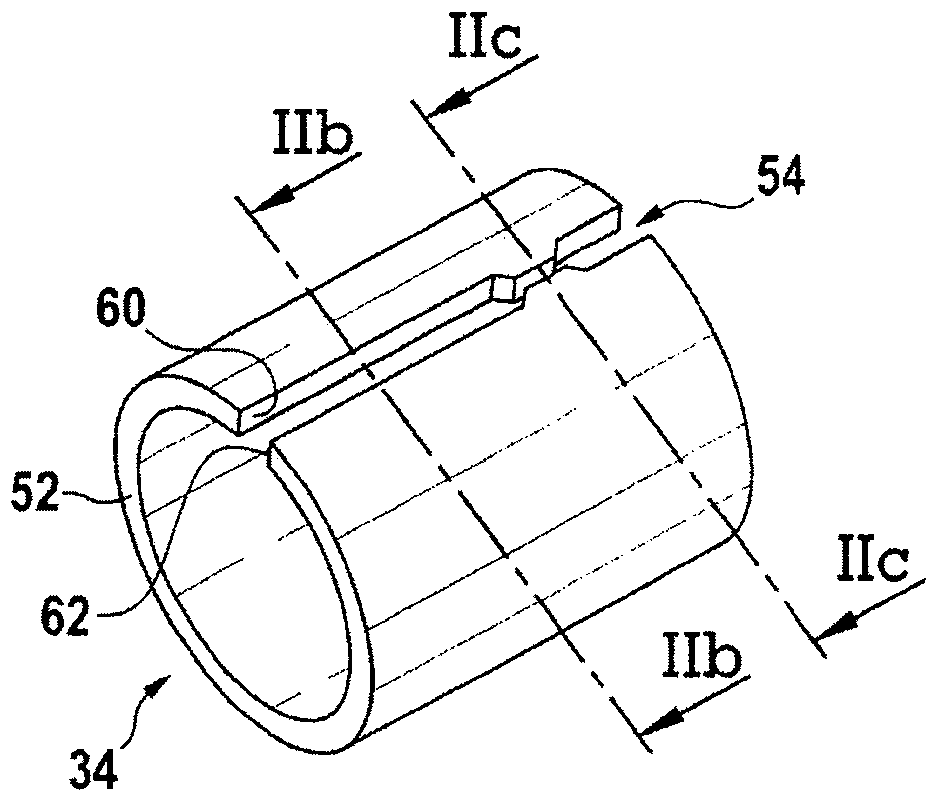

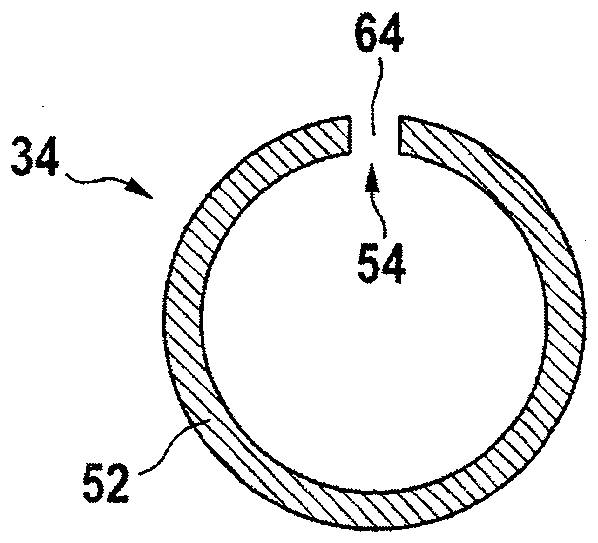

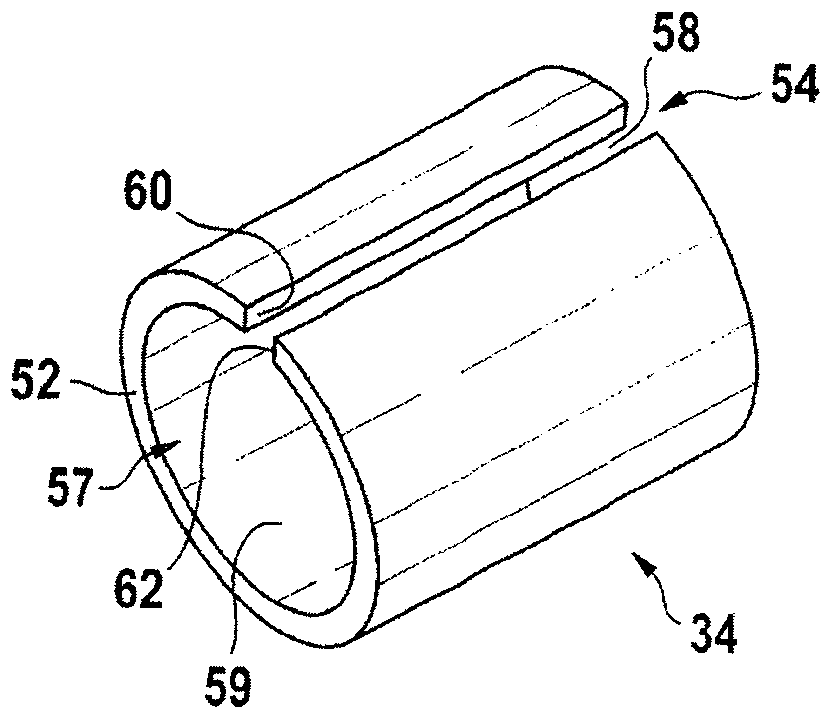

[0026] Electromagnetic control device in Figure 1aThe center bears the reference numeral 10 as a whole. Such electromagnetic actuating devices 10 are used, for example, in the transmission technology of motor vehicles, in particular for controlling clutches of automatic transmissions. For this purpose, hydraulic valves are actuated, for example, by electromagnetic actuation device 10 , said hydraulic valves Figure 1a is only schematically delineated by the box provided with the reference number 12 ).

[0027] The electromagnetic actuating device 10 has a housing 14 in which the components of the electromagnetic actuating device 10 are arranged. The electromagnetic actuating device 10 has a solenoid coil 16 which has a coil body 18 and a winding 20 . At the first end side 22 the housing 14 is closed by means of a closure 24 which can be a flux disk. On the second end side 26 the housing is closed by means of a cover 28 which can be a magnet cover 28 . Furthermore, an elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com