Slipper deformable tooth stepless meshing adjustable gear

A technology of deforming teeth and sliding vanes, applied in the direction of gear transmission, belt/chain/gear, V-belt, etc., can solve the problems of low bearing capacity and impact resistance, low transmission power, discontinuous power flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

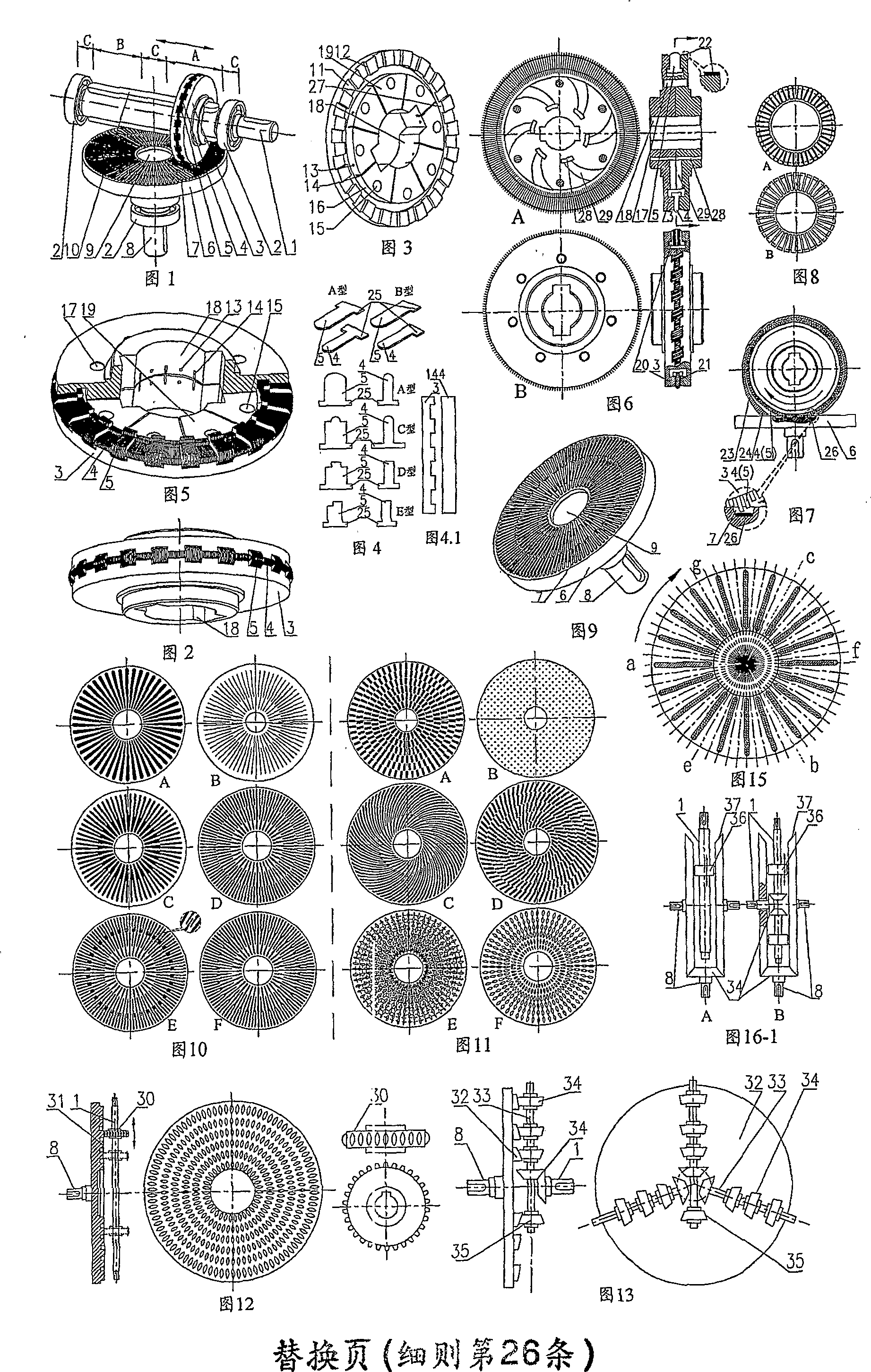

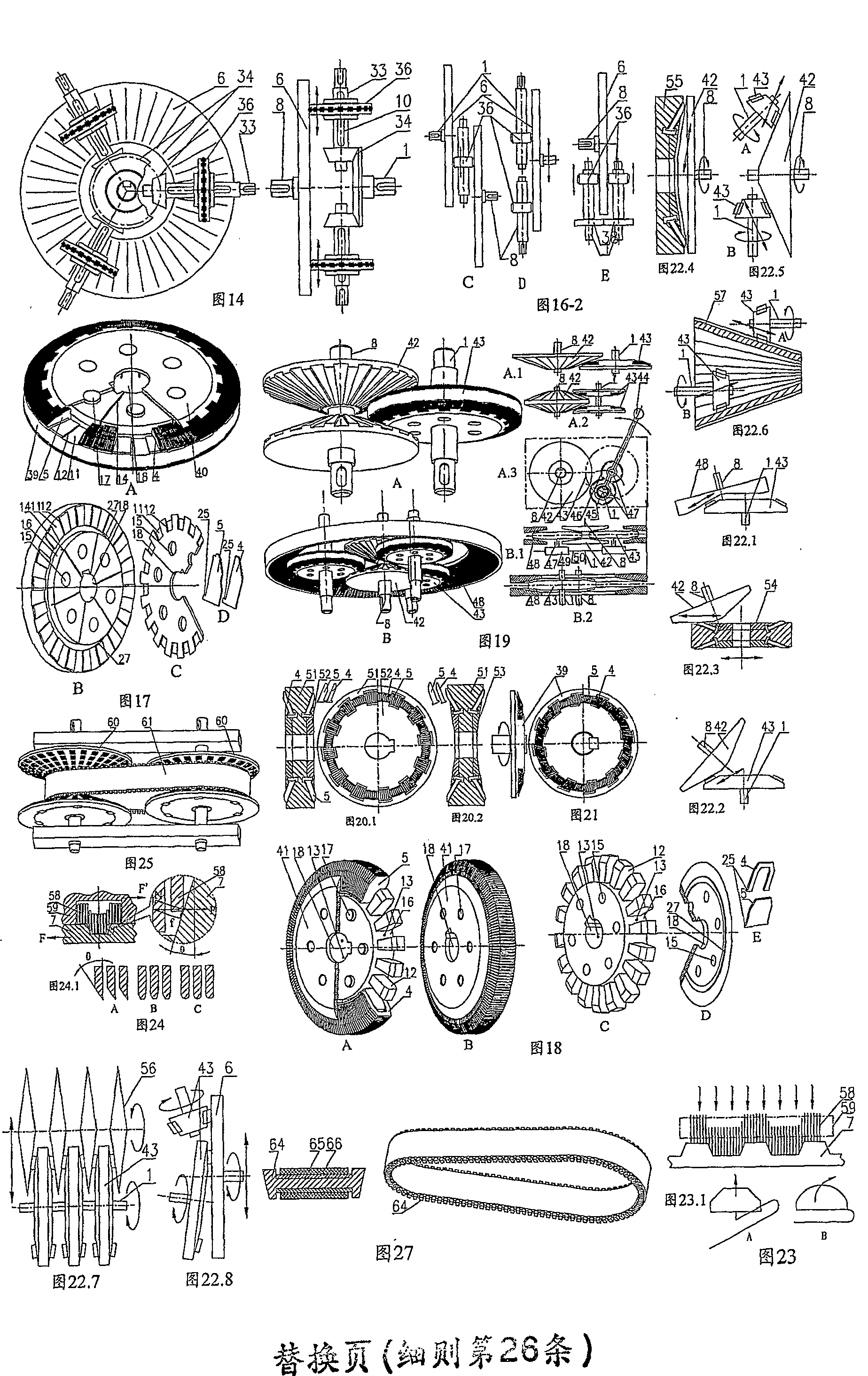

[0325] The present invention innovates and improves the shortcomings of the existing gear transmission and continuously variable transmission, and provides a new type of continuously variable transmission on this basis to meet and adapt to the needs of modern industries, especially the needs of the automobile industry, and to meet and expand It breaks down most of the current CVT functions and realizes the unique "non-friction gear meshing CVT", which is a new concept of high-power and high-efficiency (close to gear transmission efficiency) mechanical CVT.

[0326] Technical scheme of the present invention is as follows:

[0327] Basic working principle: The entire working surface of the gear is composed of a large number of thin slides (or sliding needles). The free and stepless sliding of the slides can form an meshing tooth shape of any shape. This design idea is equivalent to the gear Microelement segmentation can form any desired tooth shape through the organic combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com