Drying coating technology for sodium percarbonate

A sodium percarbonate and process technology, applied in the field of dry coating technology, can solve the problems of sodium percarbonate and dry coating, and achieve the effects of good fluidity, compact surface and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

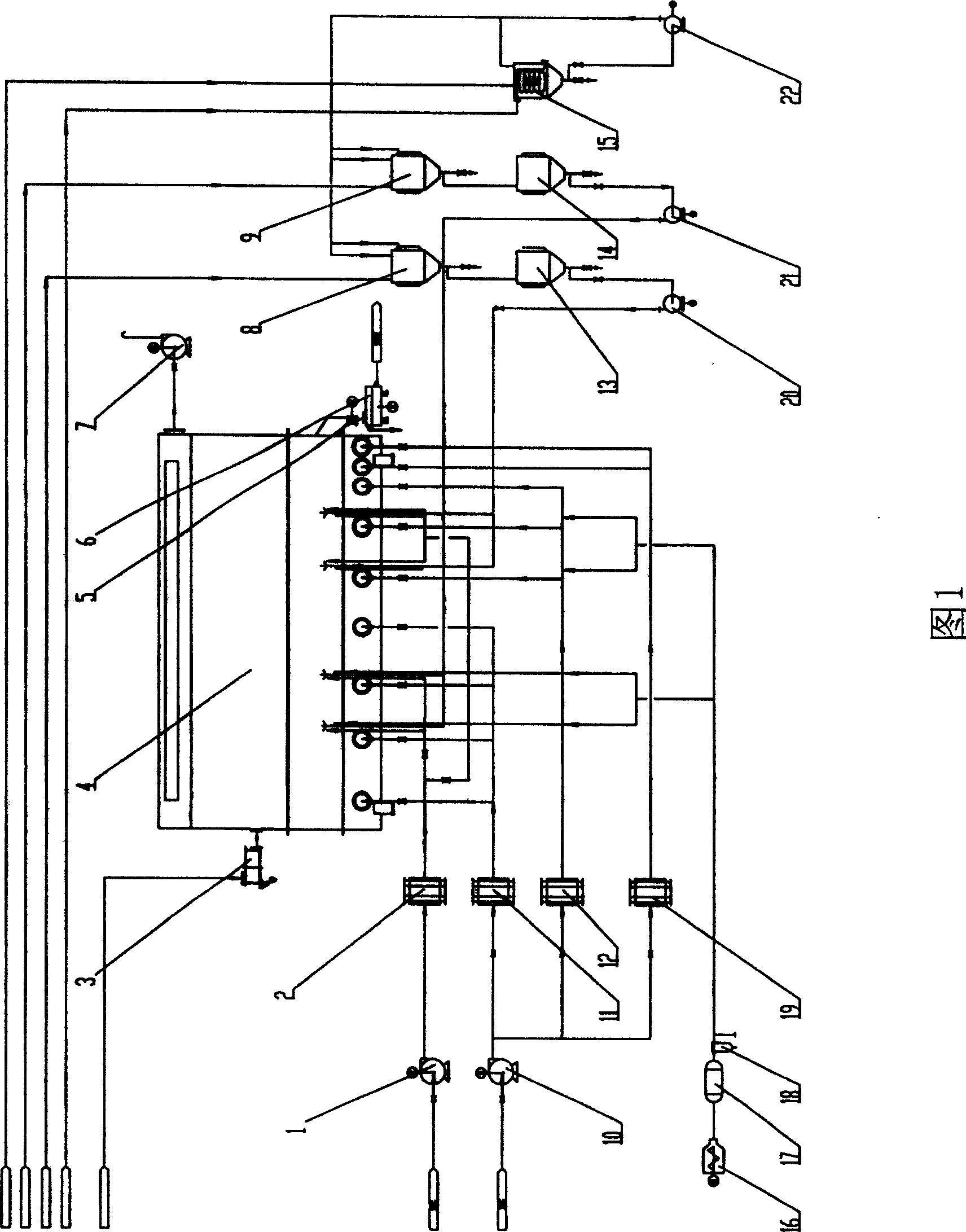

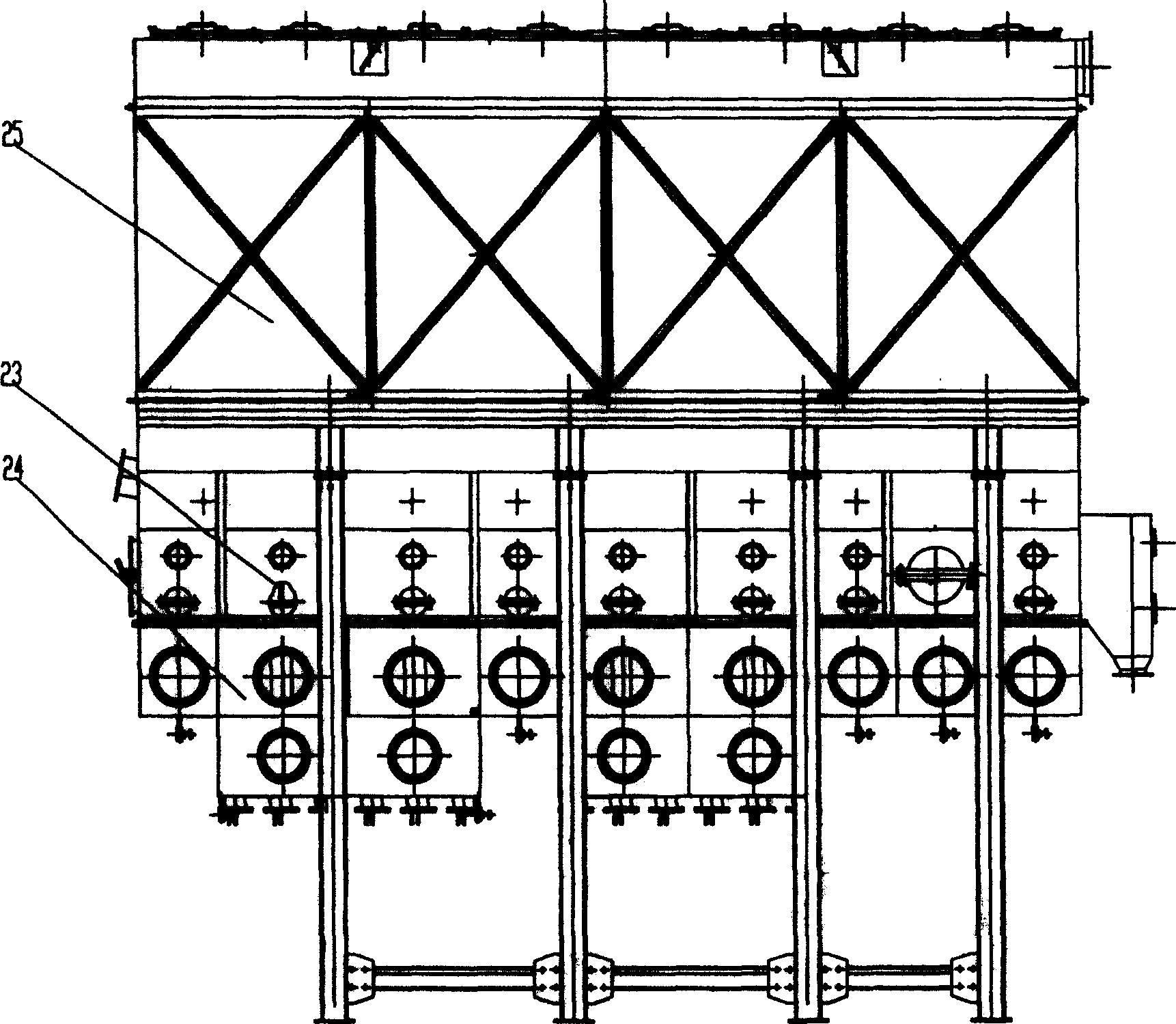

[0022] Example: by Figure 1 and figure 2 It can be seen that sodium percarbonate is added to the feed bin on the vibrating feeder 3, and the material enters the spray fluidized bed dryer 4 through the vibrating feeder 3 with variable speed regulation, and is mixed in the primary mixing tank 9 and the secondary mixing tank simultaneously. The coating material mixed by feed tank 8 and process hot water is atomized by the two-fluid nozzle and sprayed onto the particles in a fluidized state, and by means of the heat and reaction heat of the sodium percarbonate particles and the coating solution itself, the The coating solution completes agglutination, coating, evaporation and crystallization on the surface of the sodium percarbonate particles, and completes the drying process and cooling process in the spray fluidized bed dryer 4 . Part of the fine particle material entrained by the exhaust gas in the spray fluidized bed is separated by the built-in bag filter 25 of the spray flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com