Linear guide rail

A technology of linear guides and guides, applied in the field of linear guides, can solve the problems of large friction coefficient of linear guides and low lifespan of guides, and achieve the effects of good follow-up, improved response speed and sensitivity, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

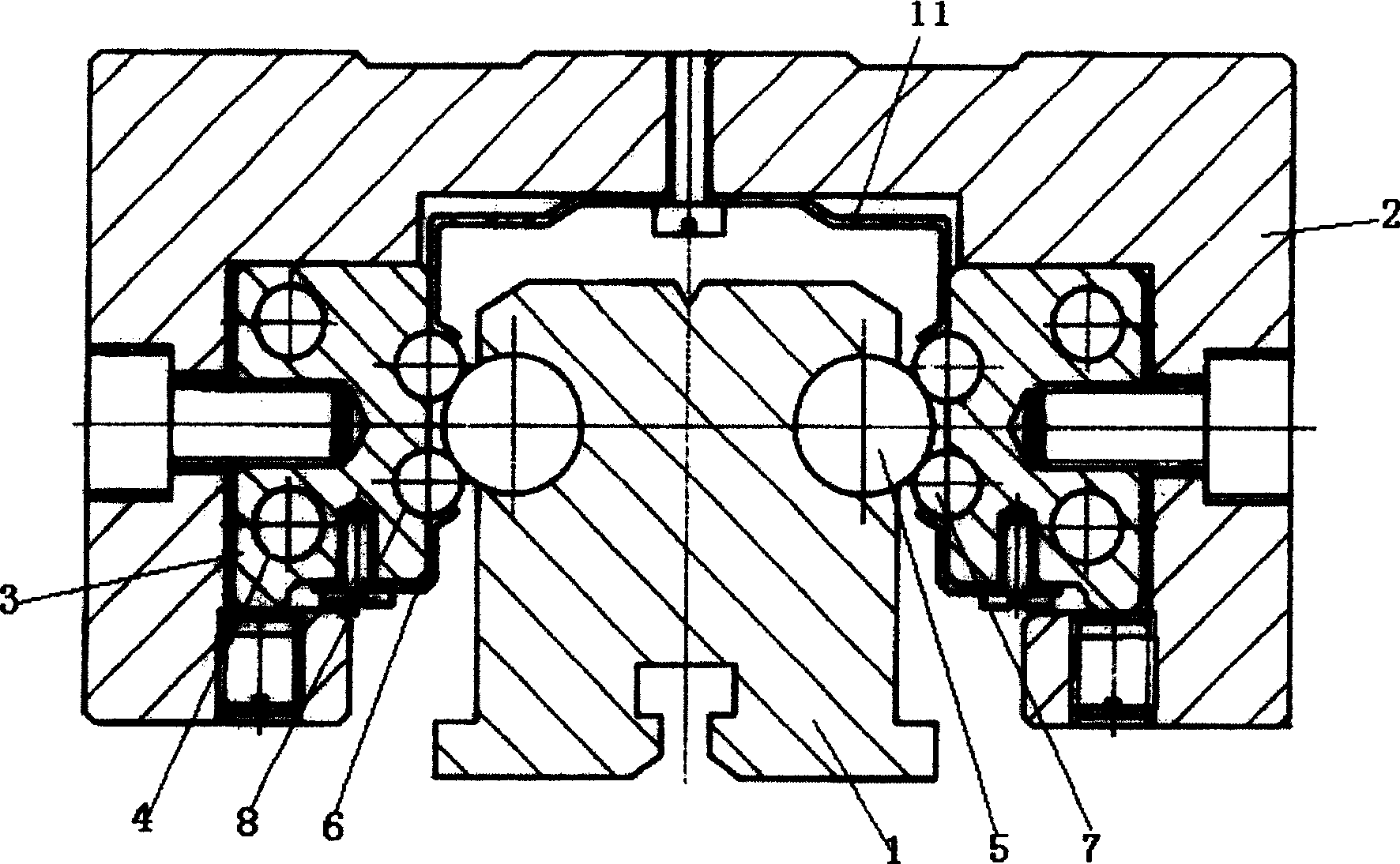

[0021] Further illustrate the present invention below in conjunction with accompanying drawing.

[0022] see figure 1 , the linear guide rail of the present invention includes a guide rail and a slider, and the slider is slidably fixed on the guide rail. The guide rail includes a guide rail main body 1 and a cylindrical guide rail 5; The axis of symmetry is provided with an arc-shaped track groove, and the cylindrical guide track 5 is embedded in the track grooves on both sides of the guide rail main body.

[0023] The slider includes a slider body 2 and bearings.

[0024] The slider main body 2 is a door shape, and grooves are symmetrically arranged on the inner sides of the door frames on both sides of the slider main body

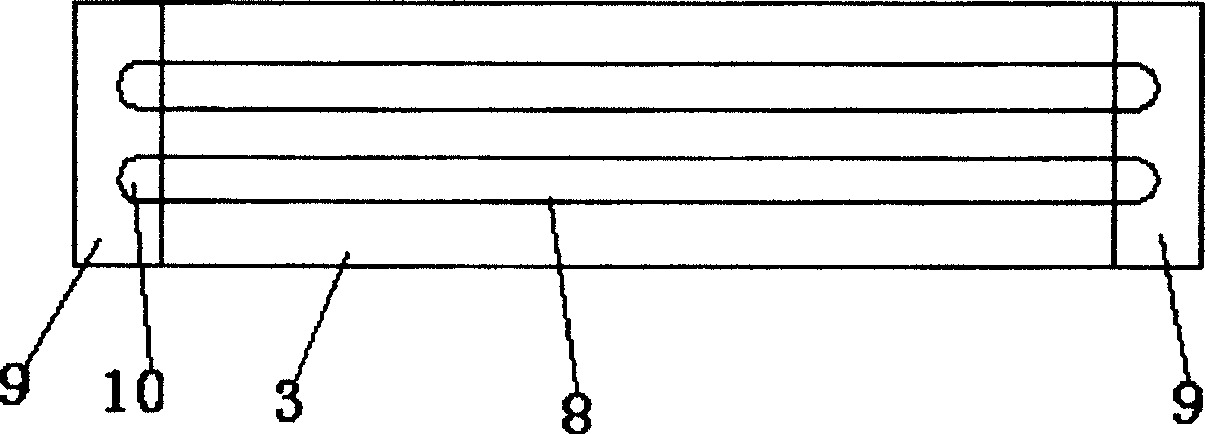

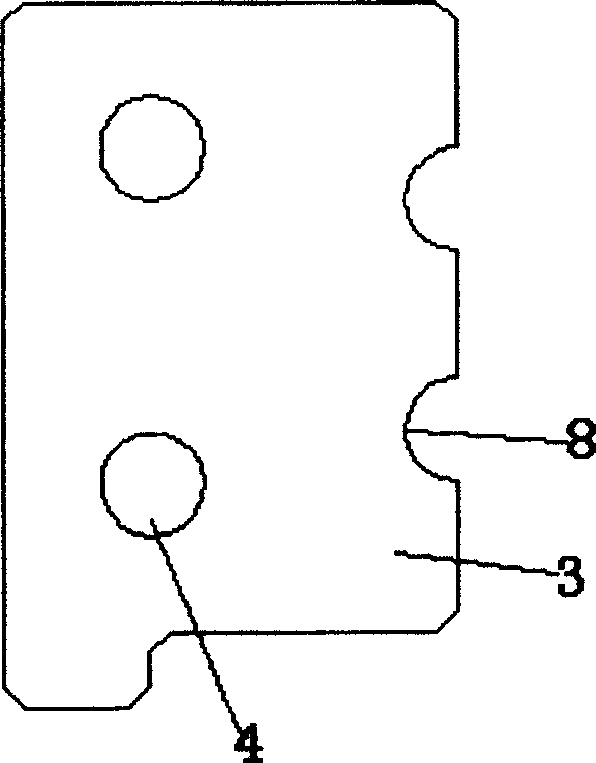

[0025] see figure 1 , figure 2 , image 3 , the bearing includes a bearing main body 3, steel balls 7, and end caps 9, the end caps 9 are fixedly arranged at both ends of the bearing main body 3, and the bearing main body 3 is fixedly arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com